Continuous Eucommia jelly freeze-out device

A technology of eucommia gum and freeze-out, which is applied in the field of continuous eucommia jelly freeze-out device, which can solve the problems of difficult separation of suspended solids in continuous production, failure to meet the industrial production of eucommia gum, and accelerated freeze-out of heat transfer coefficient, etc., to achieve convenient Industrialization and large-scale production, the effect of eliminating solvent leakage and improving the overall heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with accompanying drawing, the present invention is described in further detail.

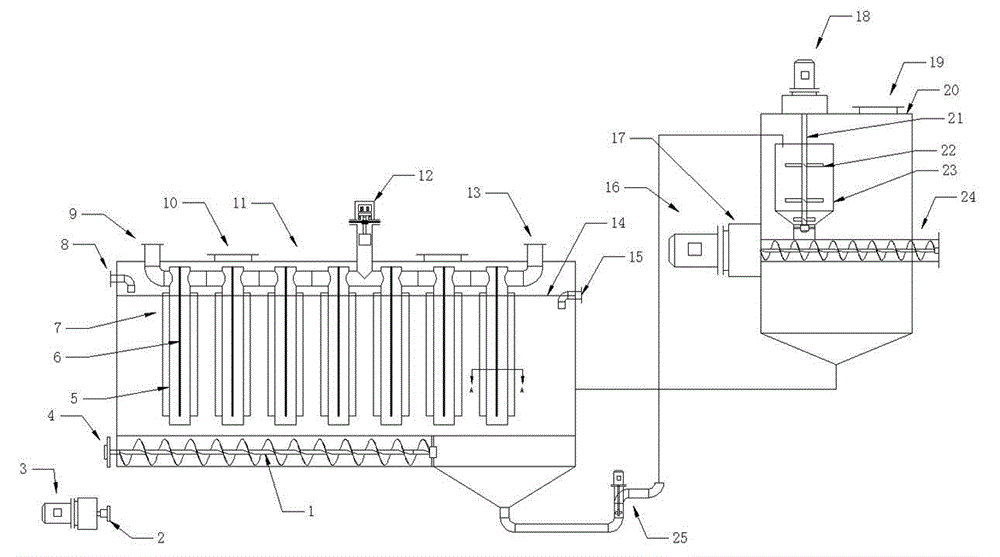

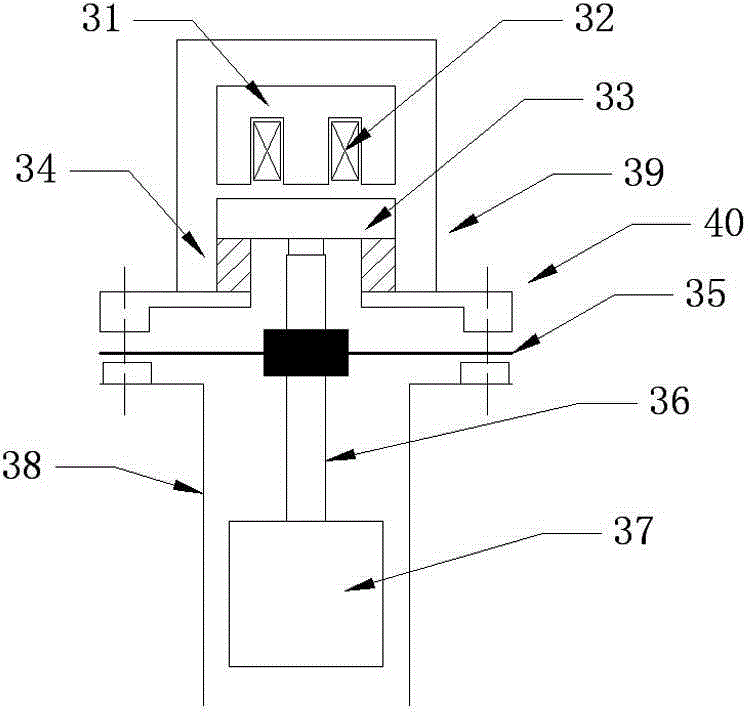

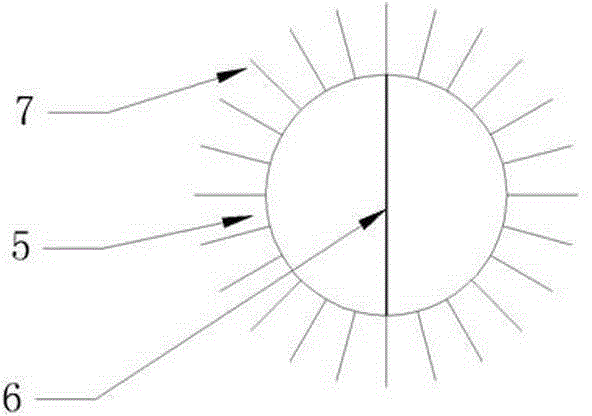

[0022] Such as figure 1 , figure 2 with image 3 The continuous eucommia jelly freeze-out device shown comprises a freeze-out bucket 11, and the freeze-out bucket 11 is provided with a chilled water inlet pipe 13. The water pipe 9 passes through the freeze-out bucket 11, the heat exchange tube 5 has fins 7 and is placed vertically, and the chilled water pipe 13 is connected with a water hammer exciter 12; Pipe 15; one side of the bottom of the freeze-out bucket 11 is provided with a screw conveyor 1, and the screw conveyor 1 is driven by a motor 3 with a reducer through two small sprockets to drive a large sprocket 4; the other side of the bottom of the freeze-out bucket 11 is an inverted Conical structure, the axial flow pump 25 passes through the solid-liquid separation barrel 20 to connect to the sieve barrel 23, the sieve barrel 23 is provided with a stirring de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com