Method and device for salt separation and crystallization of high-salinity wastewater in coal chemical industry

A technology for high-salt wastewater and coal chemical industry, applied in chemical instruments and methods, mining wastewater treatment, multi-stage water treatment, etc., can solve the problems of high operating costs, large equipment footprint, high energy consumption, and achieve low operating costs. , the effect of small footprint and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

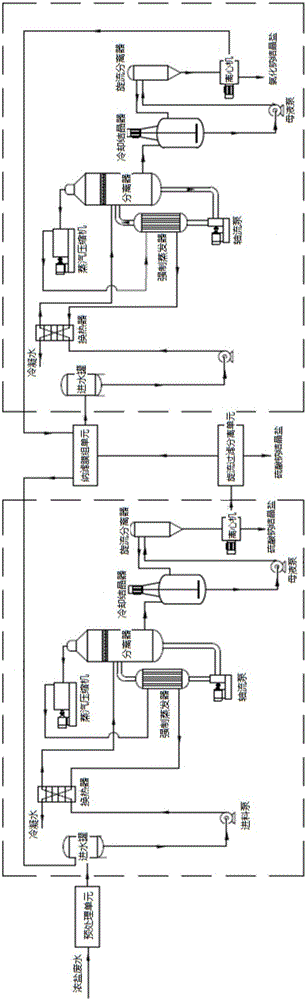

Image

Examples

Embodiment 1

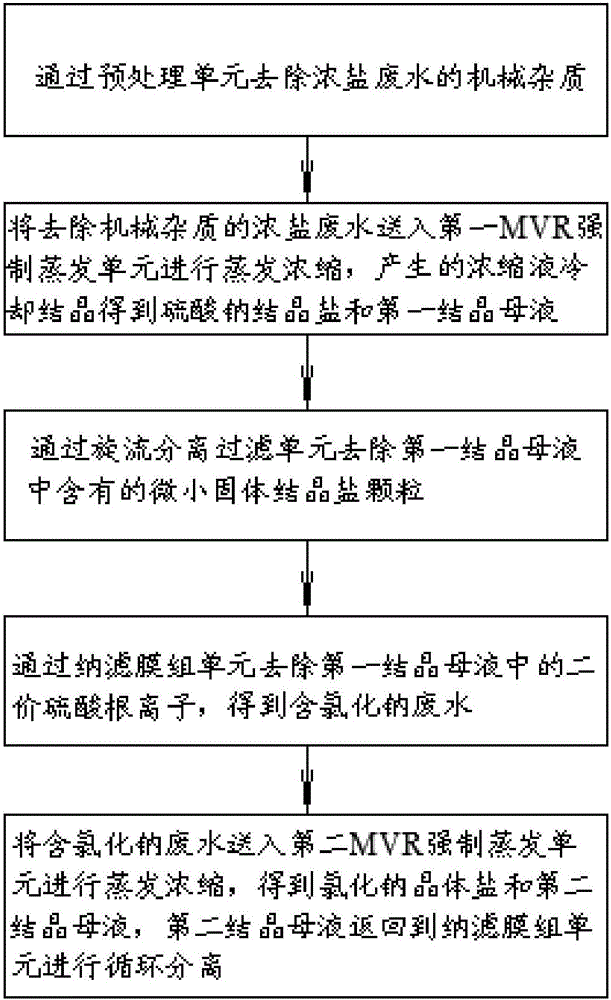

[0066] S1: The flow rate is 1m 3 / h, the high-salt wastewater with a total salt content of 30,000-15,000 mg / L, the mechanical impurities of high-salt wastewater from coal chemical industry are removed through the pretreatment unit.

[0067] S2: Send the coal chemical high-salt wastewater from which mechanical impurities have been removed to the first MVR forced evaporation unit for evaporation and concentration, and the resulting concentrated solution is cooled and crystallized to obtain sodium sulfate crystalline salt and the first crystallization mother liquor. The technical parameters of the steam compressor in the first MVR forced evaporation unit are: the inlet pressure is 105KPa; the outlet pressure is 160KPa.

[0068] S3: removing tiny solid crystalline salt particles contained in the first crystallization mother liquor through a cyclone separation and filtration unit.

[0069] S4: Removing divalent sulfate ions in the first crystallization mother liquor through the na...

Embodiment 2

[0072] S1: The flow rate is 1m 3 / h, the high-salt wastewater with a total salt content of 30,000-15,000 mg / L, the mechanical impurities of high-salt wastewater from coal chemical industry are removed through the pretreatment unit.

[0073] S2: Send the coal chemical high-salt wastewater from which mechanical impurities have been removed to the first MVR forced evaporation unit for evaporation and concentration, and the resulting concentrated solution is cooled and crystallized to obtain sodium sulfate crystalline salt and the first crystallization mother liquor. The technical parameters of the steam compressor in the first MVR forced evaporation unit are: the inlet pressure is 110KPa; the outlet pressure is 170KPa.

[0074] S3: removing tiny solid crystalline salt particles contained in the first crystallization mother liquor through a cyclone separation and filtration unit.

[0075] S4: Removing divalent sulfate ions in the first crystallization mother liquor through the na...

Embodiment 3

[0078] S1: The flow rate is 1m 3 / h, the high-salt wastewater with a total salt content of 30,000-15,000 mg / L, the mechanical impurities of high-salt wastewater from coal chemical industry are removed through the pretreatment unit.

[0079] S2: Send the coal chemical high-salt wastewater from which mechanical impurities have been removed to the first MVR forced evaporation unit for evaporation and concentration, and the resulting concentrated solution is cooled and crystallized to obtain sodium sulfate crystalline salt and the first crystallization mother liquor. The technical parameters of the steam compressor in the first MVR forced evaporation unit are: the inlet pressure is 115KPa; the outlet pressure is 180KPa.

[0080] S3: removing tiny solid crystalline salt particles contained in the first crystallization mother liquor through a cyclone separation and filtration unit.

[0081] S4: Removing divalent sulfate ions in the first crystallization mother liquor through the na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com