Preparation method of magnetic imprinted polymer for separating and purifying ractopamine

A technology of imprinted polymers and ractopamine, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of magnetic iron tetroxide leakage and other problems, achieve good paramagnetism, fast adsorption rate, and satisfy the effect of rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

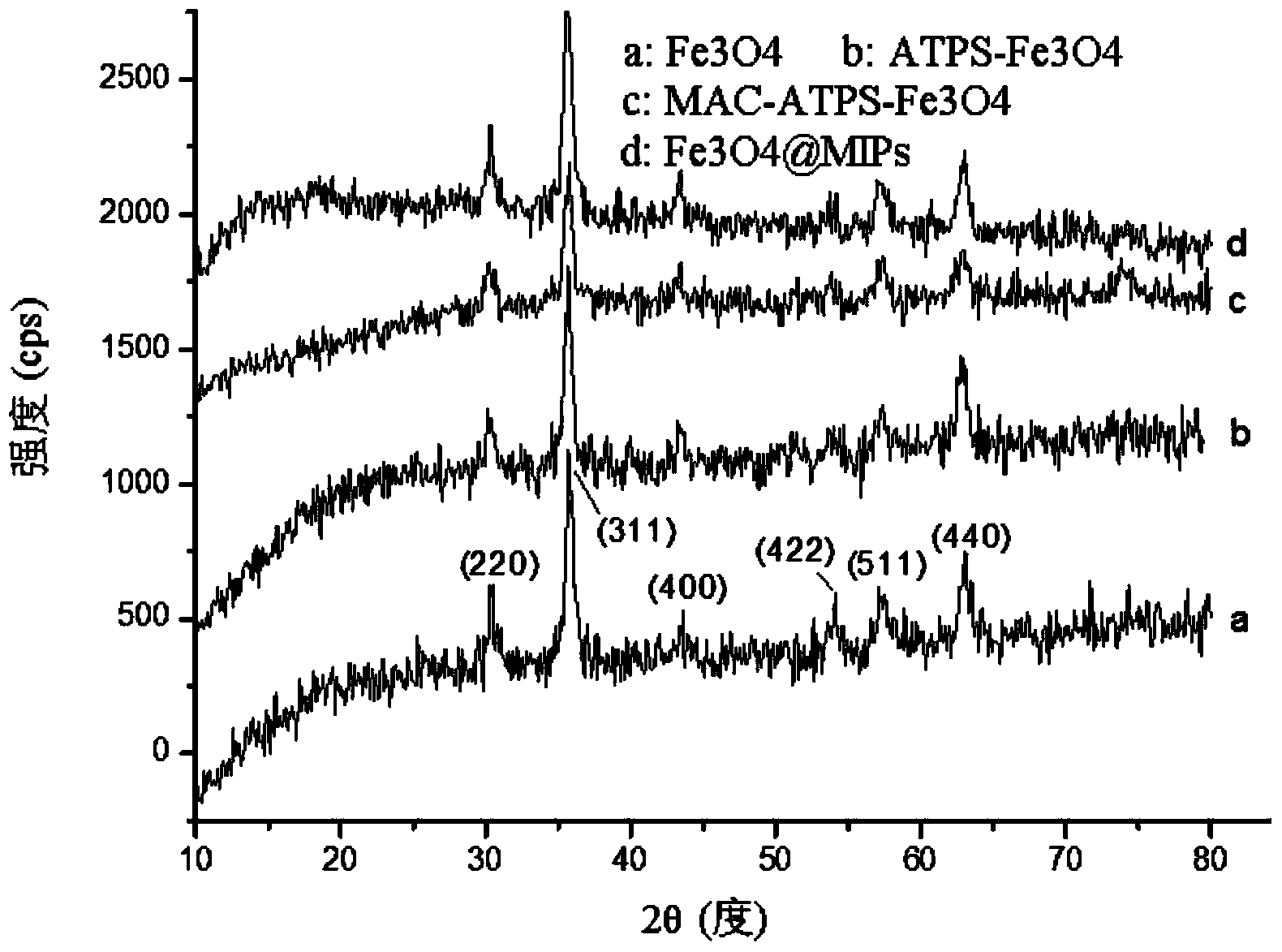

[0041] The preparation method of the magnetically imprinted polymer for separating and purifying ractopamine of the present invention, the steps are as follows:

[0042] (1) Preparation of magnetic iron tetroxide (Fe 3 o 4 ) nanospheres:

[0043] FeCl 2 4H 2 O and FeCl 3 ·6H 2 O was placed in a three-necked flask, deionized water after ultrasonic degassing was added, and mechanically stirred under nitrogen protection; then the reaction system was heated and ammonia water was added drop by drop, and after the addition was completed, it was crystallized at a constant temperature; after the crystallization was completed, the temperature was naturally lowered To room temperature, use a magnet to separate the black product Fe synthesized in the solution 3 o 4 , rinse the Fe with deionized water 3 o 4 , remove the unreacted solvent until the solution is neutral, and the product is vacuum-dried for subsequent use;

[0044] (2) Preparation of 3-aminopropyltrimethoxysilane (A...

Embodiment 1

[0062] A method for preparing magnetically imprinted polymers for separating and purifying ractopamine, the steps of which are as follows:

[0063] (1) Preparation of magnetic ferric oxide nanospheres:

[0064] Take 0.03mol FeCl 2 4H 2 O and 0.06 mol FeCl 3 ·6H 2 O was added to a three-necked flask, and then 300 mL of deionized water after ultrasonic degassing was added, and mechanically stirred under nitrogen protection. Heat the reaction system to 65°C and add 60mL ammonia water dropwise. After the dropwise addition, crystallize at a constant temperature at 65°C for 60 minutes; after the crystallization is completed, let the temperature drop to room temperature naturally, and use a magnet to separate the black product Fe 3 o 4 , rinse the Fe with deionized water 3 o 4 , remove the unreacted solvent until the solution is neutral, and the product is vacuum-dried at 45°C for 24h before use.

[0065] (2) Preparation of 3-aminopropyltrimethoxysilane (ATPS) modified ferric...

Embodiment 2

[0072] A method for preparing magnetically imprinted polymers for separating and purifying ractopamine, the steps of which are as follows:

[0073] (1) Preparation of magnetic ferric oxide nanospheres:

[0074] Take 0.03mol FeCl 2 4H 2 O and 0.06 mol FeCl 3 ·6H 2 O was added to a three-necked flask, then 240 mL of deionized water after ultrasonic degassing was added, mechanically stirred under the protection of nitrogen, the reaction system was heated to 60 °C, and 54 mL of ammonia water was added dropwise, and after the addition was completed, it was crystallized at a constant temperature at 60 °C for 80 min; After the crystallization is completed, the temperature is naturally lowered to room temperature, and the black product Fe synthesized in the solution is separated by a magnet. 3 o 4 , rinse the Fe with deionized water 3 o 4 , remove the unreacted solvent until the solution is neutral, and the product is vacuum-dried at 40° C. for 30 h before use.

[0075] (2) Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com