Pulverized fuel ash-cement foam material for controlling spontaneous combustion of coal and preparation method of pulverized fuel ash-cement foam material

A technology for spontaneous combustion of coal and foam materials, which can be used in ceramic products, other household appliances, household appliances, etc., and can solve the problems of low blocking strength, high cost, and damage to the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

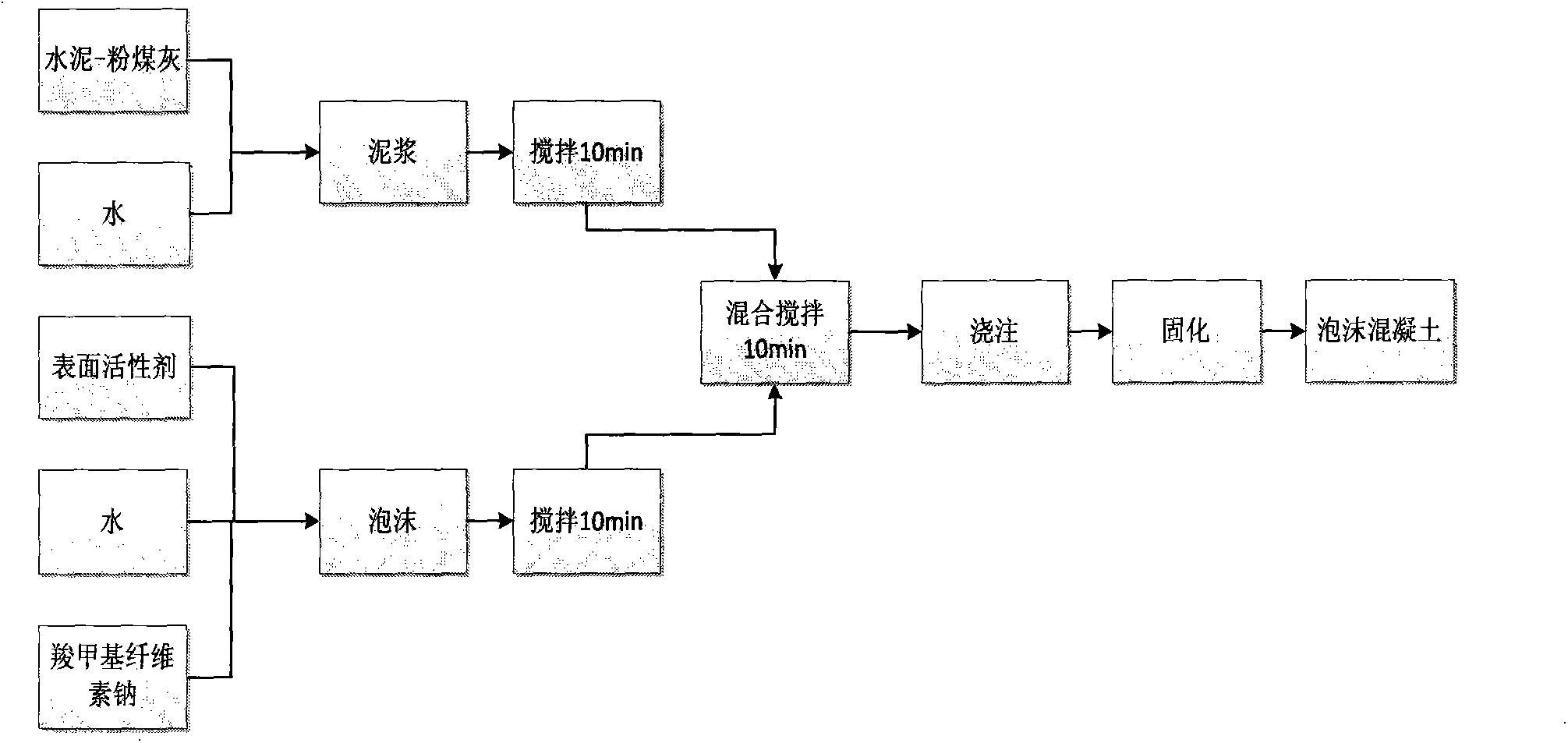

Method used

Image

Examples

Embodiment 1

[0008] Example 1: This embodiment is made of the following components: (amount is weight percent) sulfoaluminate superfine cement 20, fly ash 20, carboxymethyl cellulose 0.2-0.3, sodium fluoride 0.1-0.3, 0.1-0.3 of melamine, 0.1-0.3 of aluminum sulfate, 0.3-0.6 of sodium lauryl sulfate, 0.4-0.6 of sodium dodecylbenzenesulfonate, and the rest is water, and the amounts of all components are percentages by weight.

Embodiment 2

[0009] Example 2: This embodiment is made from the following components: (amount is weight percentage) sulfoaluminate superfine cement 15, fly ash 25, carboxymethyl cellulose 0.5, sodium fluoride 0.2-0.3, melamine 0.1 -0.3, aluminum sulfate 0.1-0.3, sodium lauryl sulfate 0.4-0.6, sodium dodecylbenzenesulfonate 0.4-0.6, and the rest is water, and the amounts of all components are weight percentages.

Embodiment 3

[0010] Example 3: This embodiment is made from the following components: (amount is weight percentage) sulfoaluminate superfine cement 25, fly ash 15, carboxymethyl cellulose 0.5, sodium fluoride 0.2-0.3, melamine 0.1 -0.3, aluminum sulfate 0.1-0.3, sodium lauryl sulfate 0.4-0.6, saponin 0.5-0.6, the rest is water, and the amounts of all components are weight percentages.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com