A kind of epoxy mortar bridge deck thin-layer pavement material and its construction method

An epoxy mortar and paving material technology, applied in the field of bridge deck paving materials, can solve the problems of reduced waterproof performance, strict construction process, unstable low temperature performance, etc., and achieves good high and low temperature performance, excellent chemical corrosion resistance, Easy and convenient mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A construction method for paving a bridge deck epoxy mortar thin layer, comprising the steps of:

[0041] a. Preparation of binder:

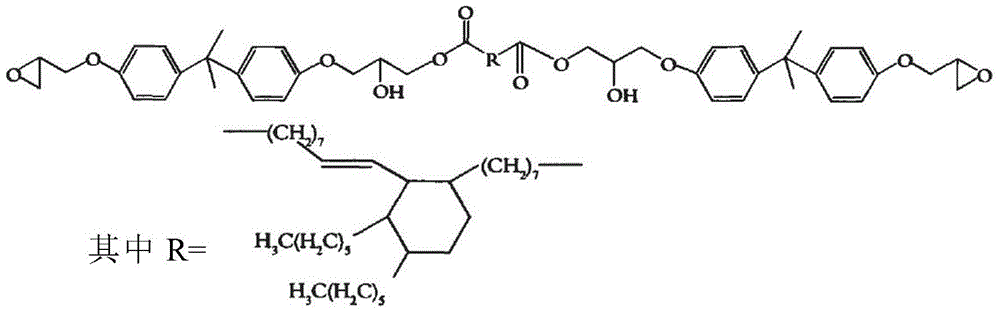

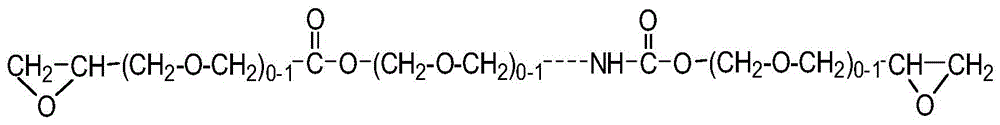

[0042] 1) React the following components in parts by mass: 65 parts of epoxy resin, 10 parts of dimer acid modified epoxy resin, 5 parts of toughening agent, and 20 parts of diluent at a temperature of 130-140 °C for 6 hours to obtain the resin A;

[0043] 2) Put the following components in parts by mass: 30 parts of polyetheramine D230, 30 parts of polyetheramine D400, 18 parts of polyetheramine D2000, 3 parts of aminoethylpiperazine AEP, accelerator DMP-30 3 parts, mixed and reacted at 50°C for 30-50 minutes to obtain modified amine curing agent B;

[0044] 3) Mix resin A and modified amine curing agent B according to the mass ratio of 1.5:1 and stir for 3 minutes to form a binder;

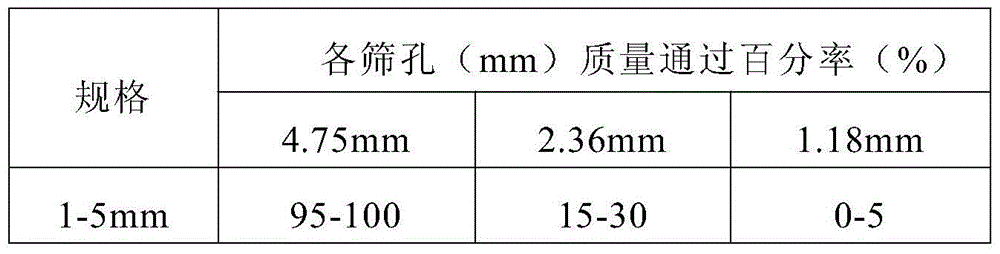

[0045] b. Preparation of epoxy mortar: Epoxy mortar is prepared from a and mixed evenly with quartz sand at a mass ratio of 1:3 and stirred for 2 minute...

Embodiment 2

[0051] A construction method for paving a bridge deck epoxy mortar thin layer, comprising the steps of:

[0052] a. Preparation of binder:

[0053] 1) React the following components in parts by mass: 45 parts of epoxy resin, 15 parts of dimer acid modified epoxy resin, 7 parts of toughening agent, and 20 parts of diluent at a temperature of 130-140 °C for 6 hours to obtain the resin A;

[0054] 2) Put the following components in parts by mass: 30 parts of polyetheramine D230, 30 parts of polyetheramine D400, 20 parts of polyetheramine D2000, 6 parts of aminoethylpiperazine AEP, accelerator DMP-30 4 parts, mixed and reacted at 50°C for 30-50 minutes to obtain modified amine curing agent B;

[0055] 3) Mix resin A and modified amine curing agent B according to the mass ratio of 2:1 and stir for 3 minutes to form a binder;

[0056] b. Preparation of epoxy mortar: Epoxy mortar is prepared from a and mixed evenly with quartz sand at a mass ratio of 1:3 and stirred for 2 minutes....

Embodiment 3

[0062] A construction method for paving a bridge deck epoxy mortar thin layer, comprising the steps of:

[0063] a. Preparation of binder:

[0064] 1) React the following components in parts by mass: 55 parts of epoxy resin, 17 parts of dimer acid-modified epoxy resin, 6 parts of toughening agent, and 25 parts of diluent at a temperature of 130-140°C for 6 hours to obtain the resin A;

[0065] 2) Put the following components in parts by mass: 25 parts of polyetheramine D230, 30 parts of polyetheramine D400, 18 parts of polyetheramine D2000, 8 parts of aminoethylpiperazine AEP, accelerator DMP-30 3 parts, mixed and reacted at 50°C for 30-50 minutes to obtain modified amine curing agent B;

[0066] 3) Mix resin A and modified amine curing agent B at a mass ratio of 1.7:1 and stir for 3 minutes to form a binder;

[0067] b. Preparation of epoxy mortar: Epoxy mortar is prepared from a and mixed with quartz sand at a mass ratio of 1:2 and stirred evenly for 2 minutes. The quartz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com