A lightweight railway wagon underframe

A lightweight technology for railway freight cars, which is applied to railway car body components, underframes, transportation and packaging, etc., and can solve the problems of inability to fully utilize the role and efficiency of railway transportation equipment, unsatisfactory stress state of the overall structure of the vehicle, and the application of railway freight cars Different working conditions and other issues, achieve the effect of realizing lightweight design, reducing maintenance workload, and reducing the self-weight of the chassis structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. However, it should not be construed that the scope of the above-mentioned subject matter of the present invention is limited to the following examples.

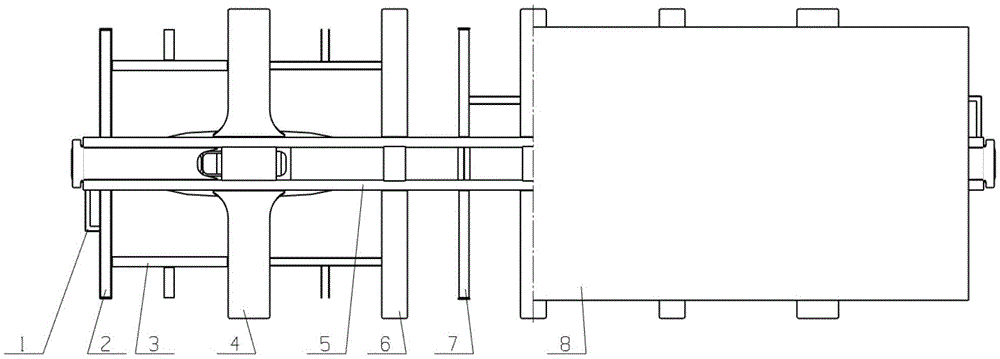

[0020] combine figure 1 — Figure 6 , a railway lightweight gondola car chassis is composed of steel floor 8, middle beam 5, corbel beam 4, large beam 6, small beam 7, tail device mounting seat 1, auxiliary beam 2 and auxiliary longitudinal beam 3, the underframe is not equipped with end beams and side beams, and the two ends of the underframe are equipped with column tail device mounting seats 1 and auxiliary beams to form 2.

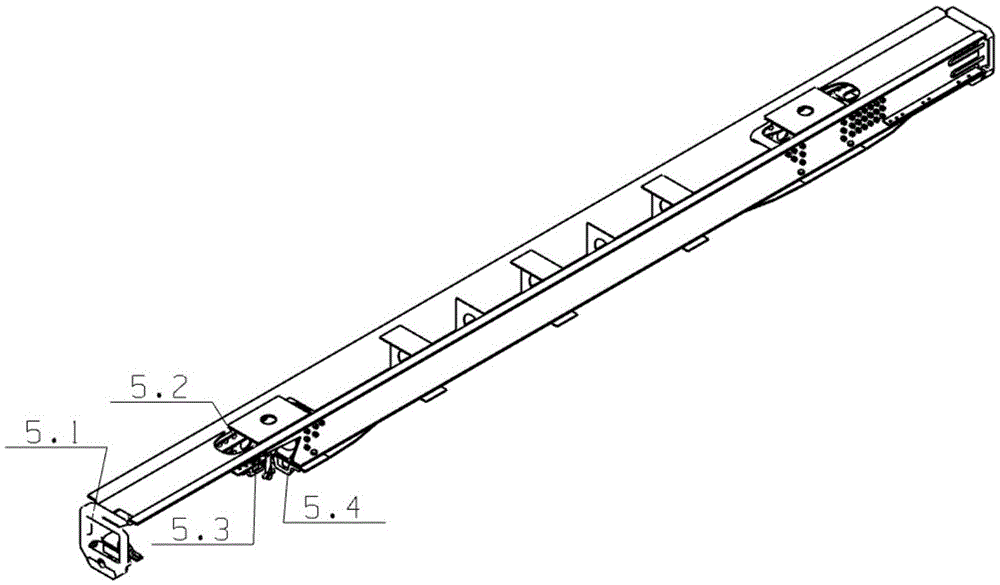

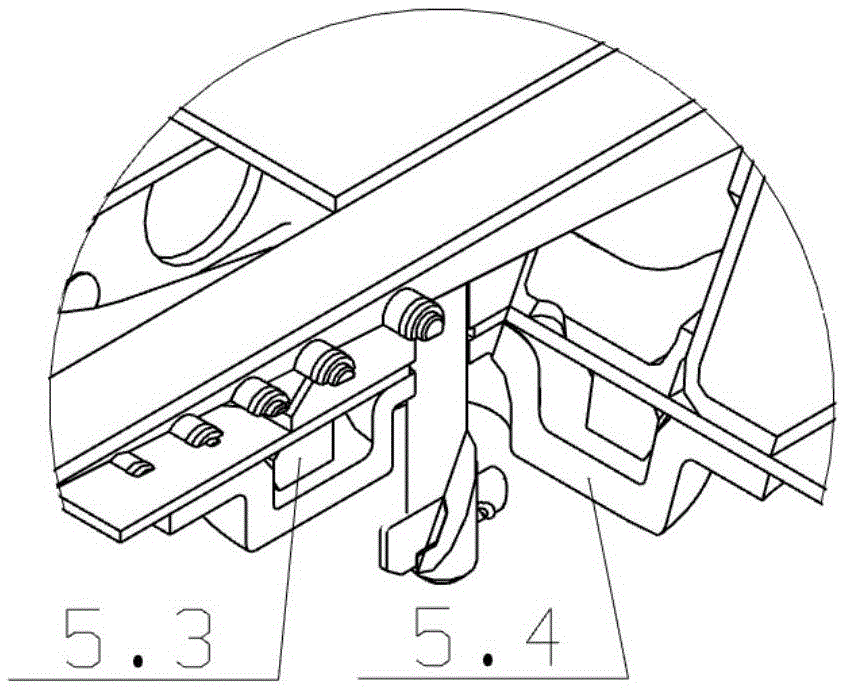

[0021] The middle beam composition 5 is located in the middle of the bottom frame along the longitudinal direction of the bottom frame. The middle beam composition 5 is assembled and welded by two cold-formed channel steels. Plate base 5.2, upper center plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com