Detection method of droplet necking in molten electrode arc welding

An arc welding and melting electrode technology, applied in the field of arc welding, can solve problems such as time delay, and achieve the effects of reducing welding spatter, good real-time and authenticity, and good welding arc dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

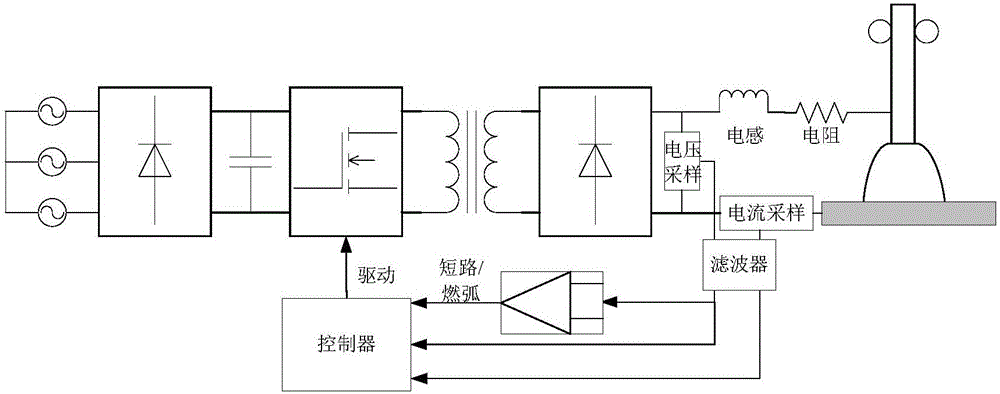

[0020] Such as Figure 6 shown. In the molten electrode welding process based on the inverter power supply, when the droplet short-circuits and the short-circuit process ends and returns to the arc, the time constant of the system will change suddenly, so the slope of the welding current will change suddenly at this moment.

[0021] Such as Figure 7 As shown, the embodiment of the present invention takes the digital signal processor (DSP) as the core, samples the welding current through the A / D unit, calculates the slope of the welding current, and compares the slope with the short circuit threshold or the arcing judgment threshold, as a reverse short circuit and arcing status flags. Among them, in order to improve the real-time performance of the judgment process, the process of sampling the welding current by the digital signal processor is repeatedly sampled, that is, the welding current is sampled multiple times within one switching cycle.

[0022] Figure 7 It is a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com