Cold rolled strip steel production technology

A production process, cold-rolled strip technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problem of affecting the stability of the emulsion and cooling effect, limiting the temperature to further increase, and the temperature of the emulsion cannot be too high, etc. problems, achieve the effect of reducing scratch defects and rolling mill vibration, reducing strip surface scratches, simple structure and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

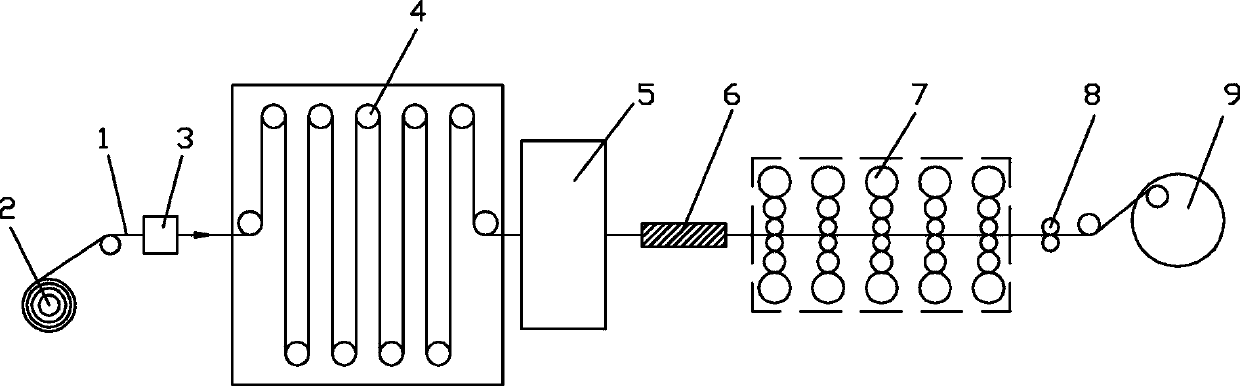

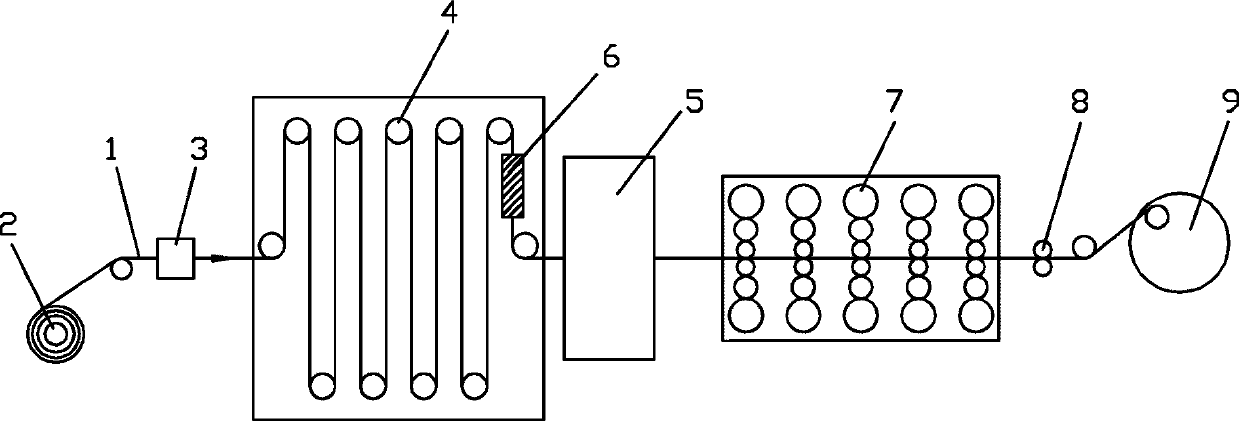

[0039] see figure 1 , image 3 , taking the situation of adding a strip heating device at the entrance side of the rolling mill as an example:

[0040]Inlet strip 1 is pickled steel plate with a thickness of 1.8mm and a width of 923mm. According to the characteristics of the emulsion of the cold tandem mill, in order to ensure a good lubrication state, it is necessary to ensure that the temperature of the strip at the entrance of the rolling mill is T 1 Keep it at about 60°C.

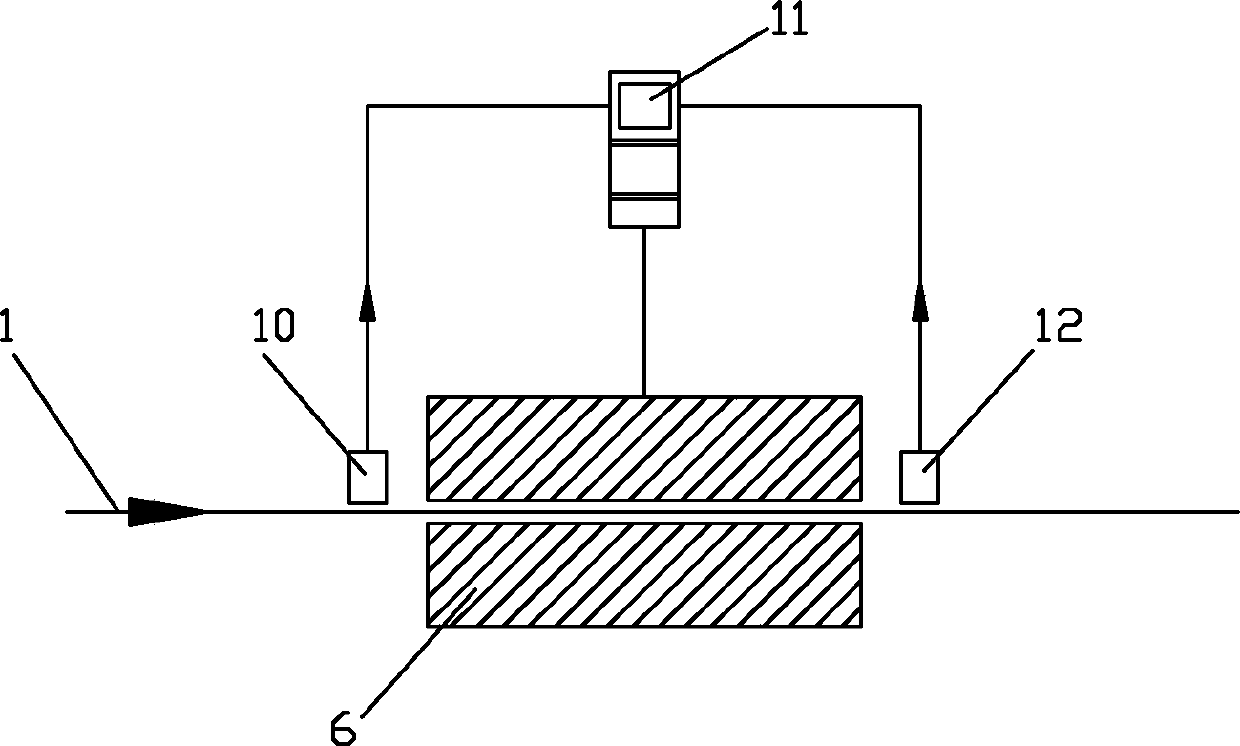

[0041] After the pickled steel strip 1 is uncoiled by the uncoiler 2, it enters the rolling mill inlet looper 4 through the welding machine 3, and then enters the strip heating device 6 after passing through the rolling mill inlet tension unit 5, and is arranged on the strip heating device 6 inlet side. The strip temperature detection device 10 will detect the strip temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com