Crystal jewelry processing system

A processing system and jewelry technology, applied in metal processing equipment, clothing, manufacturing tools, etc., can solve problems such as inconsistent workpiece sizes, and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a further explanation in conjunction with the accompanying drawings:

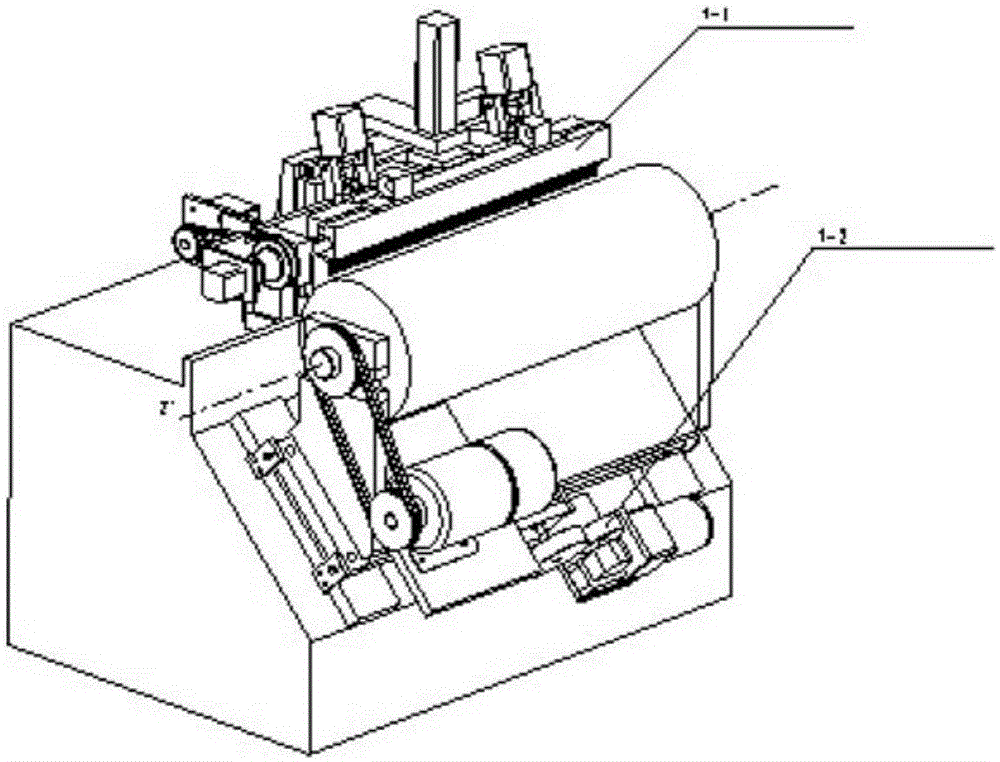

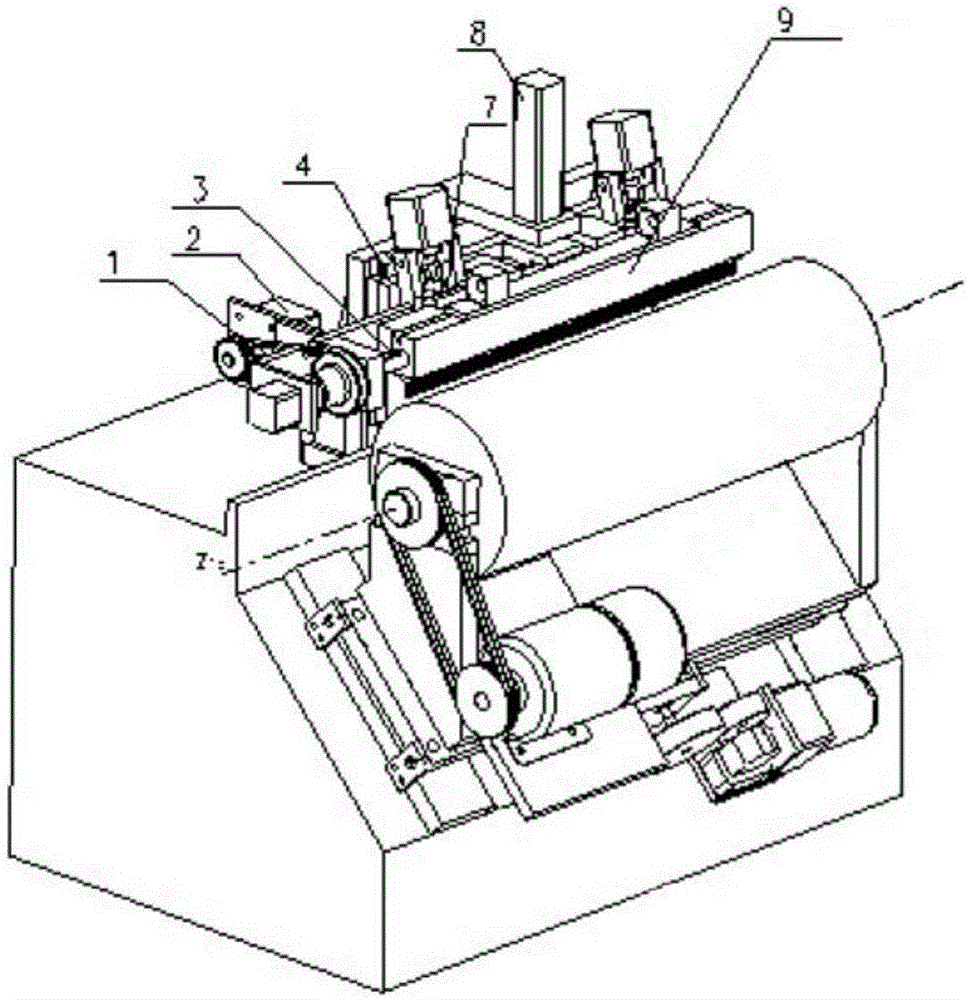

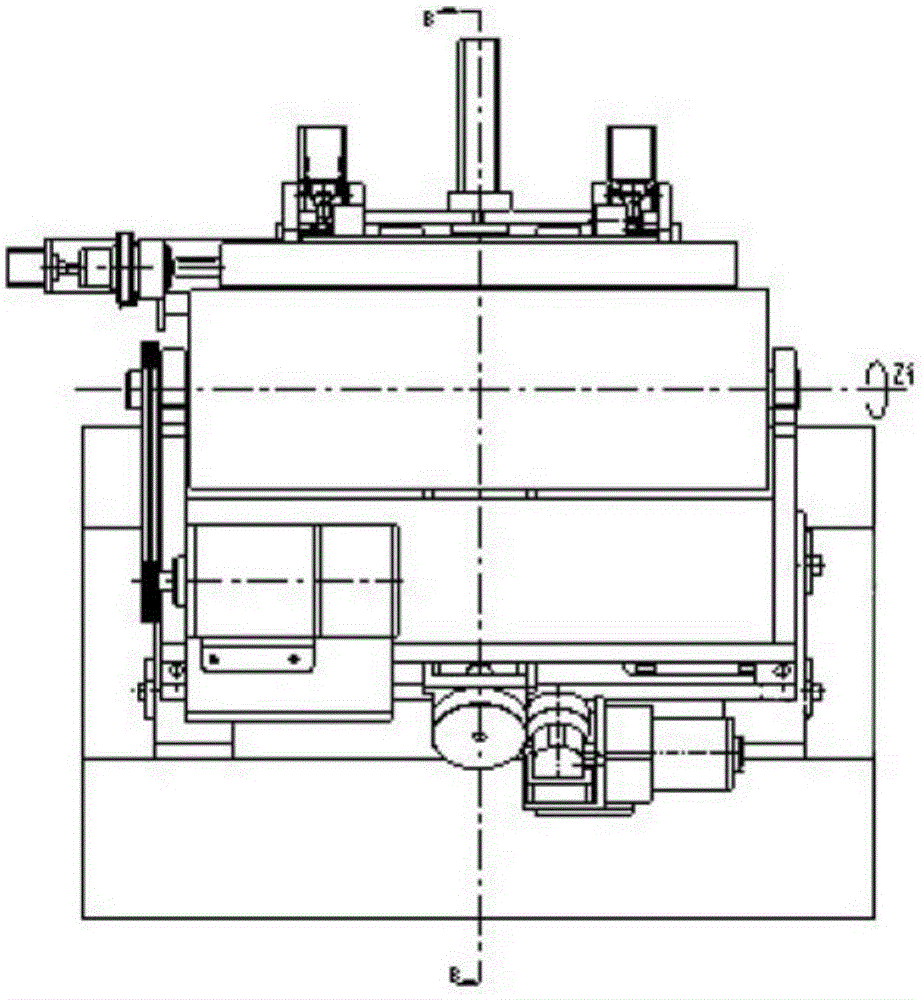

[0019] Such as Figure 1-6 As shown, the processing system of crystal jewelry includes a frame, a clamp body up and down conveying system 1-1 and a polishing wheel inclination compensation feeding system 1-2. The clamp body up and down conveying system 1-1 is installed on the upper end of the frame, and the polishing The wheel inclination compensation feed system 1-2 is installed on one side of the frame.

[0020] Polishing wheel inclination compensation feed system, which includes stepper motor 1, coupling 2, worm gear reducer 3, keyway, screw nut mechanism 9, polishing wheel assembly 7, stepper motor 1 is connected by coupling 2 Worm gear reducer 3, worm gear reducer 3 output shaft is connected to gear 4 through keyway, gear 4 is connected to screw nut mechanism through keyway, screw nut mechanism is connected to sliding guide mechanism 8, screw nut mechanism 9 drives polishing wheel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com