Assembly type concrete whole-process monitoring system based on Internet of Things

A monitoring system and prefabricated technology, applied in the transmission system, comprehensive factory control, digital transmission system, etc., can solve problems such as difficulty in ensuring construction, lack of specifications and technical regulations, and simple component forms, so as to solve the shortage of labor force and improve the overall quality. The effect of improving quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to clearly illustrate the technical solutions in the present invention, preferred embodiments are given below, and detailed descriptions are given in conjunction with the accompanying drawings.

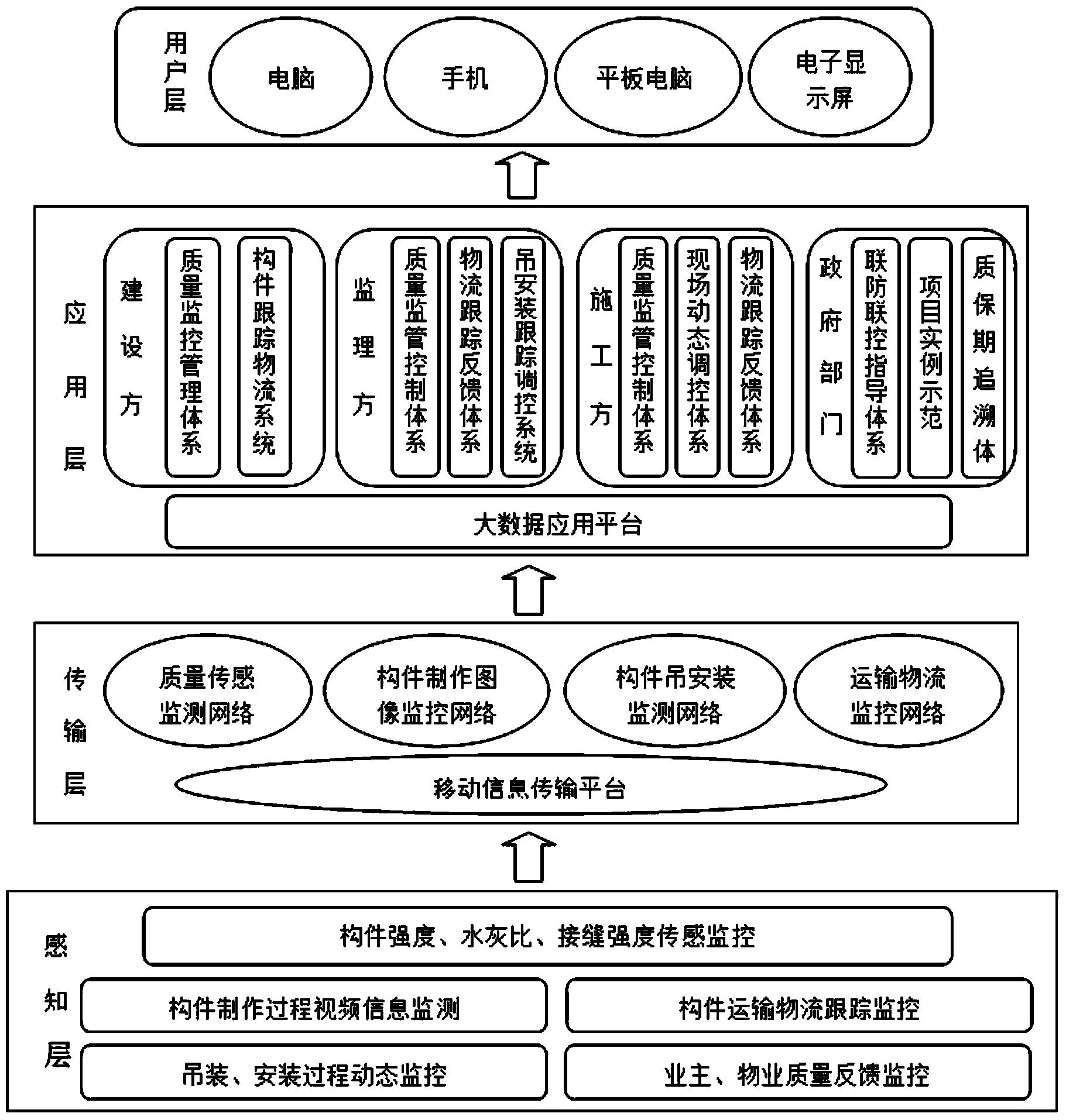

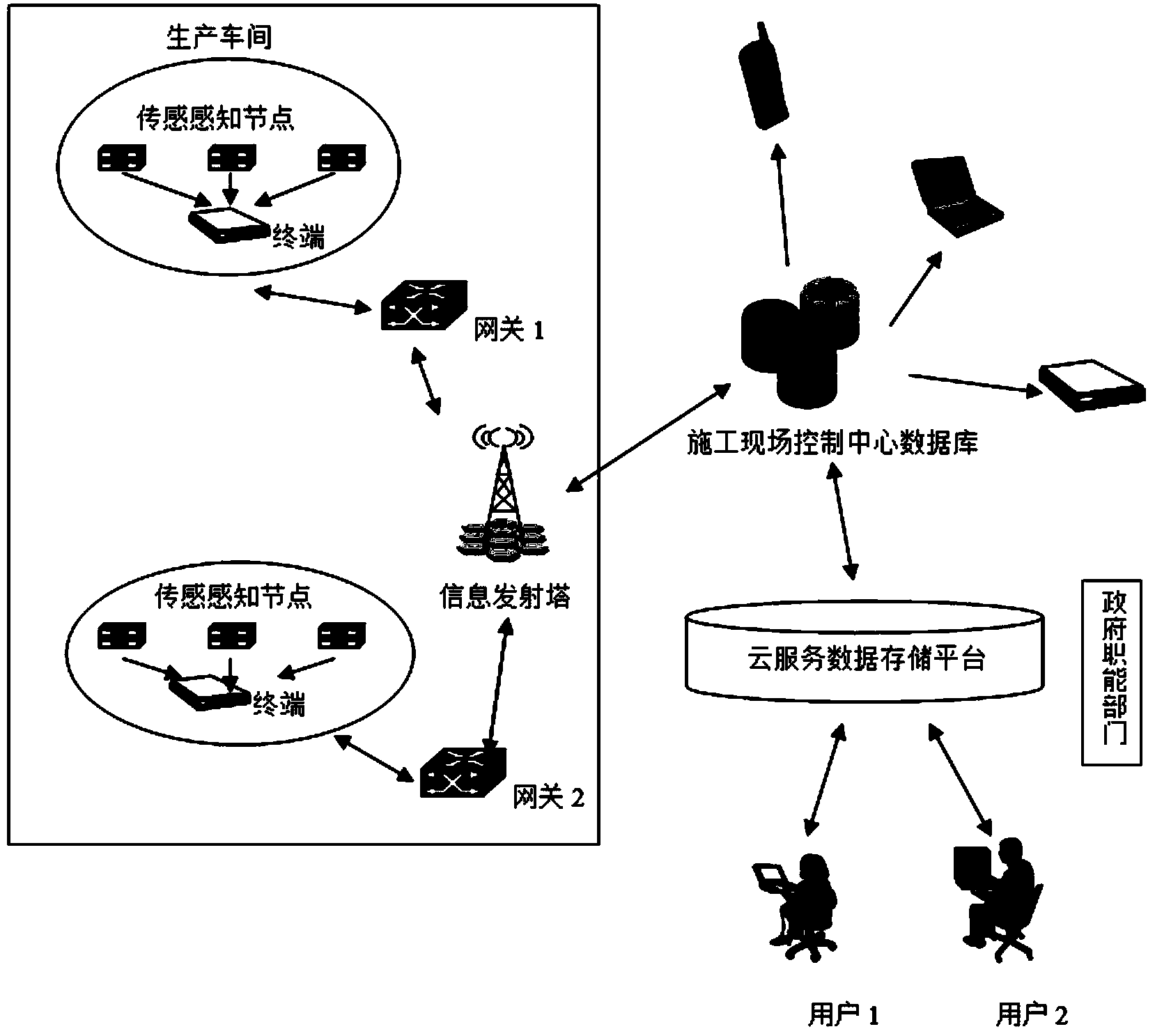

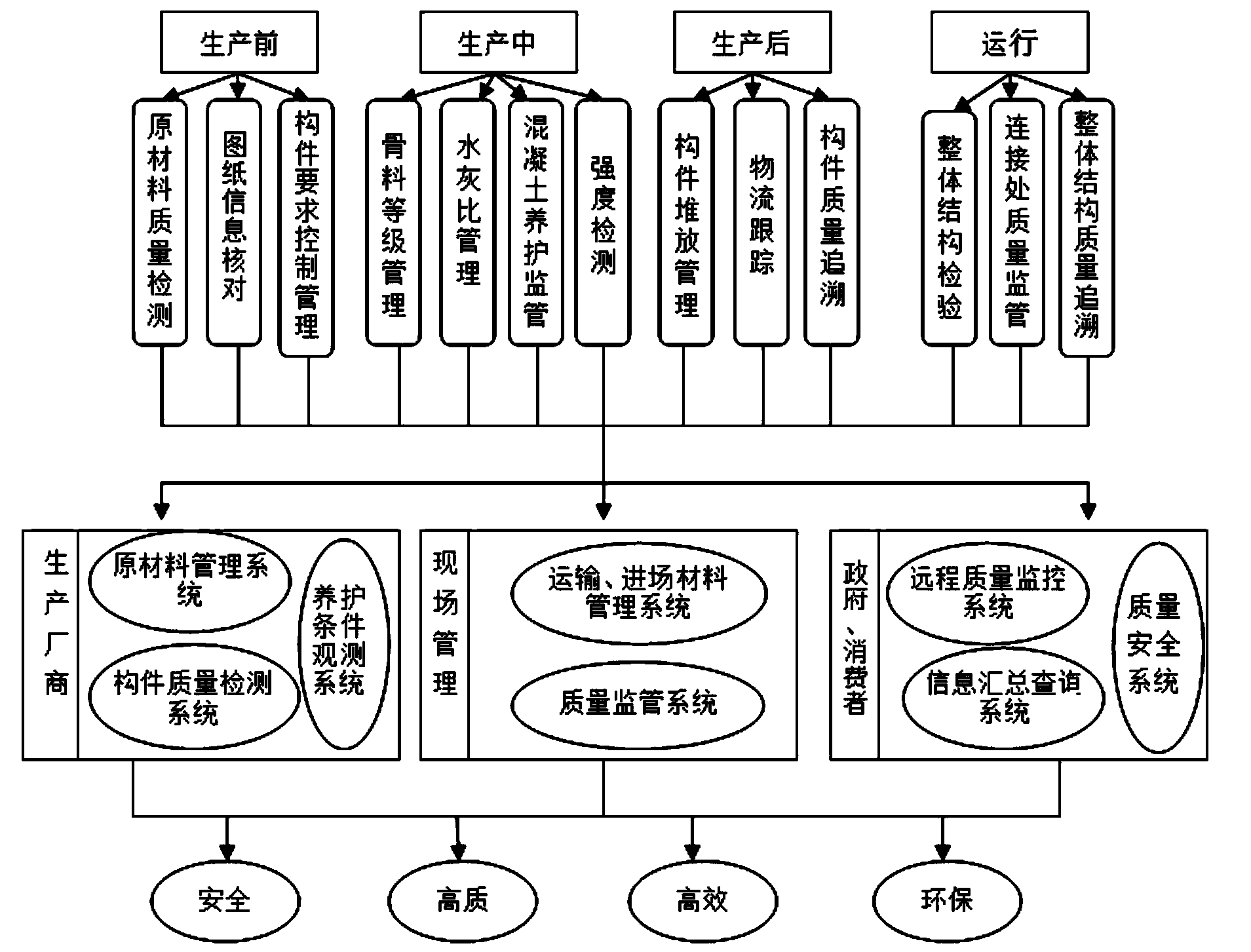

[0017] According to the current Internet of Things technology framework of various researches, and the problems existing in the four stages of pre-production, production, post-production, and operation of prefabricated concrete, the prefabricated concrete monitoring system based on the Internet of Things of the present invention is a system based on Sensing perception and wireless radio frequency technology network, wireless information transmission technology platform, which can perform real-time observation and monitoring, intelligent information transmission, and fully interconnected models to facilitate the supervision and management of construction parties, supervisors, construction parties, and relevant municipal departments.

[0018] The whole process monitoring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com