A direct-to-beam laser tractor auxiliary navigation control system

A through-beam laser and control system technology, applied in the field of control systems, can solve problems such as poor indication effect and weak adaptability, and achieve the effects of low cost, reduced labor intensity and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

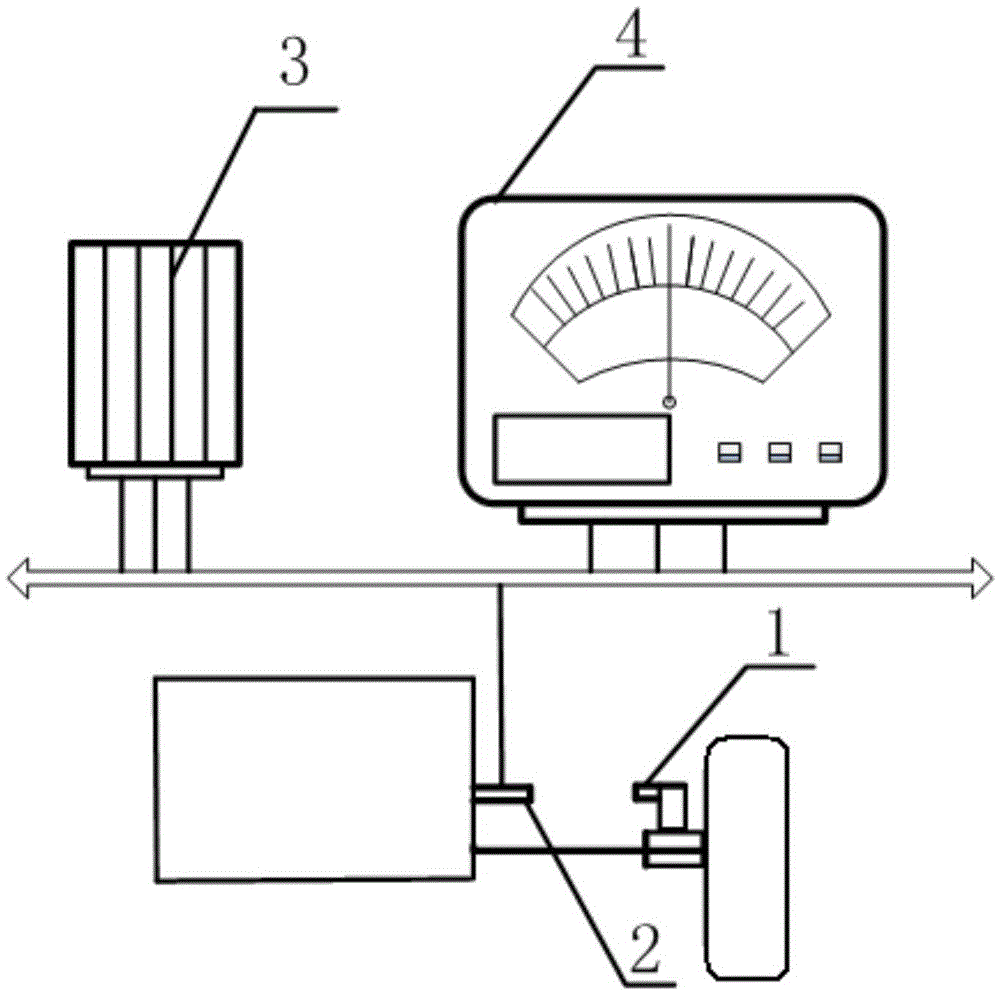

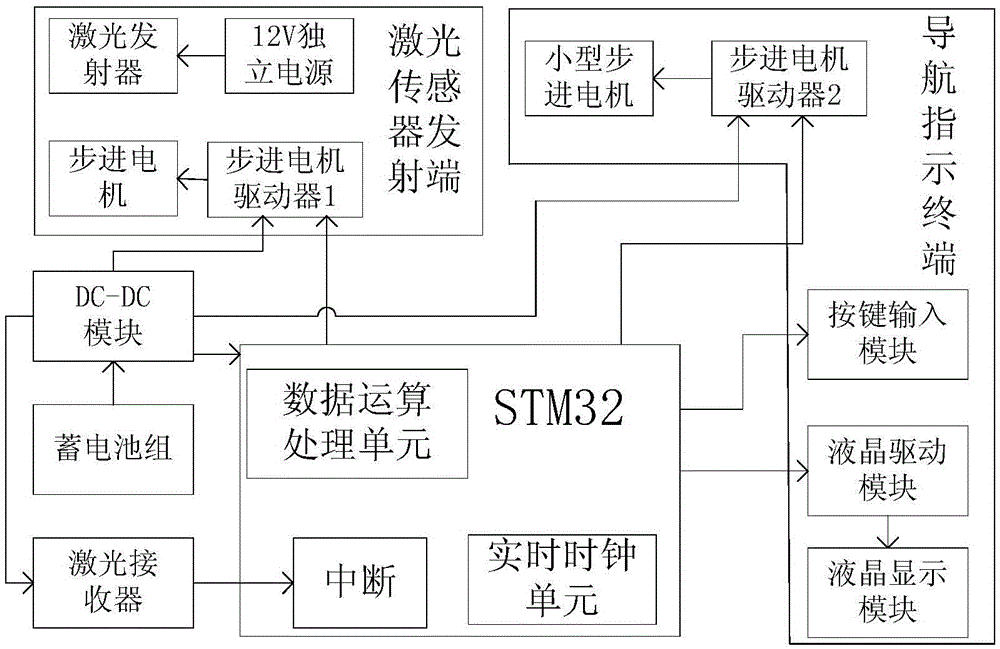

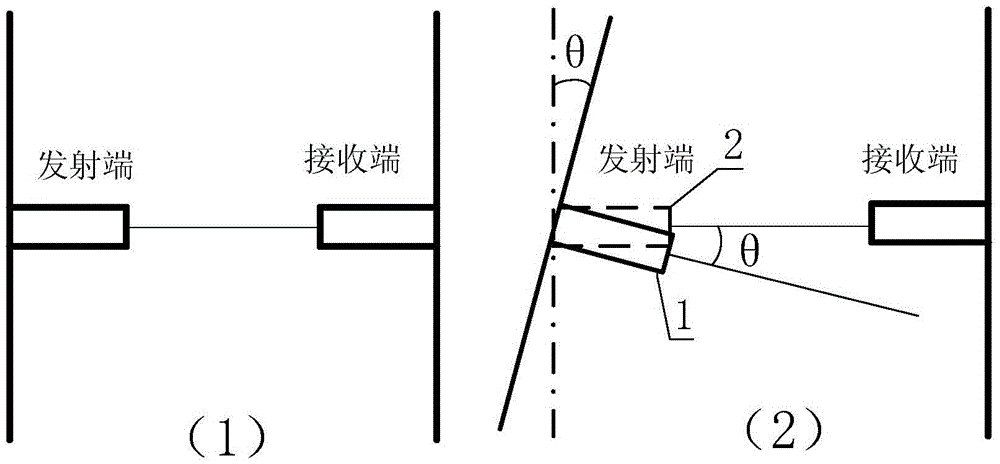

[0015] see figure 1 and figure 2 , The through-beam laser tractor auxiliary navigation control system involved in the present invention mainly includes a laser sensor transmitting terminal 1, a laser sensor receiving terminal 2, a navigation indicating terminal 4 and a control core 3.

[0016] In order to describe the implementation process of the present invention more clearly, take Dongfanghong-LX754 tractor as an example here. The laser sensor transmitter 1 is installed on the steering kingpin of the front wheel of the tractor. It consists of a through-beam laser transmitter, a laser transmitter bracket, an independent power supply, a stepper motor, a stepper motor driver and a mounting bracket. The laser transmitter is powered by 12V The independent power supply is powered, and the independent power supply and the laser emitter are fixed on the rotating shaft of the stepping motor through the laser emitter bracket, and the stepping motor is connected with the steering ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com