Test device for oxidation induction time and carbon black content of electric wire and cable sheath material

An oxidation induction period, wire and cable technology, applied in the direction of weighing by removing certain components, can solve the problems of reducing the service life of cables, not less than 20 years, and cracking of the sheath, achieving easy production, low cost, easy-to-grasp effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

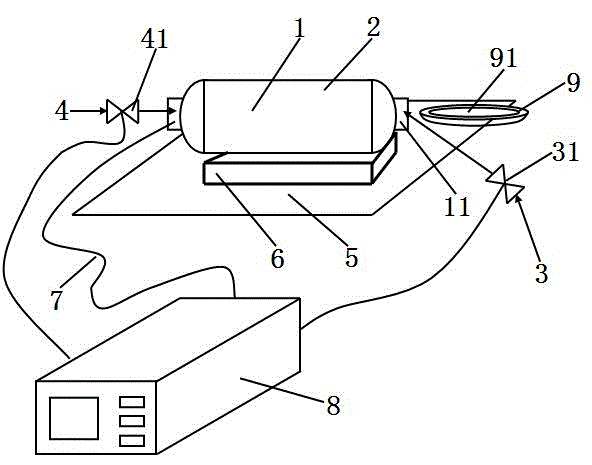

[0016] please see figure 1 , the wire and cable sheath material oxidation induction period and carbon black content testing device is characterized in that it includes: a tubular device 1, an annular heating device 2, a hollow quartz tube 11, a first solenoid valve 31, a second Electromagnetic valve 41, a carrier body 5, a support body 6, a thermocouple assembly 7, a test instrument 8, a combustion boat 9, a cork; the cork has two through connecting holes, and the cork is plugged in the quartz In the cavity at one end of the tube; the inside of the tube-shaped device has a channel that can accommodate the quartz tube and in the installed state, the quartz tube and the tube-shaped device are not in contact; the ring heating device is spirally distributed in the tube-shaped device, located at Between the channel of the quartz tube and the outer wall of the quartz tube; the output port of the first solenoid valve is connected in a connection hole of the cork, and the output port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com