Copper iron water jacket and casting forming method thereof

A technology of water jacket, copper and iron, applied in the direction of casting molding equipment, casting mold, casting mold composition, etc., can solve the cracks of the joint surface between the embedded steel plate and the copper body, the poor combination of the steel plate frame and the wall, and the plate frame and the wall Combined with problems such as poor performance, the effects of avoiding shrinkage resistance, long service life, and excellent thermal conductivity are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

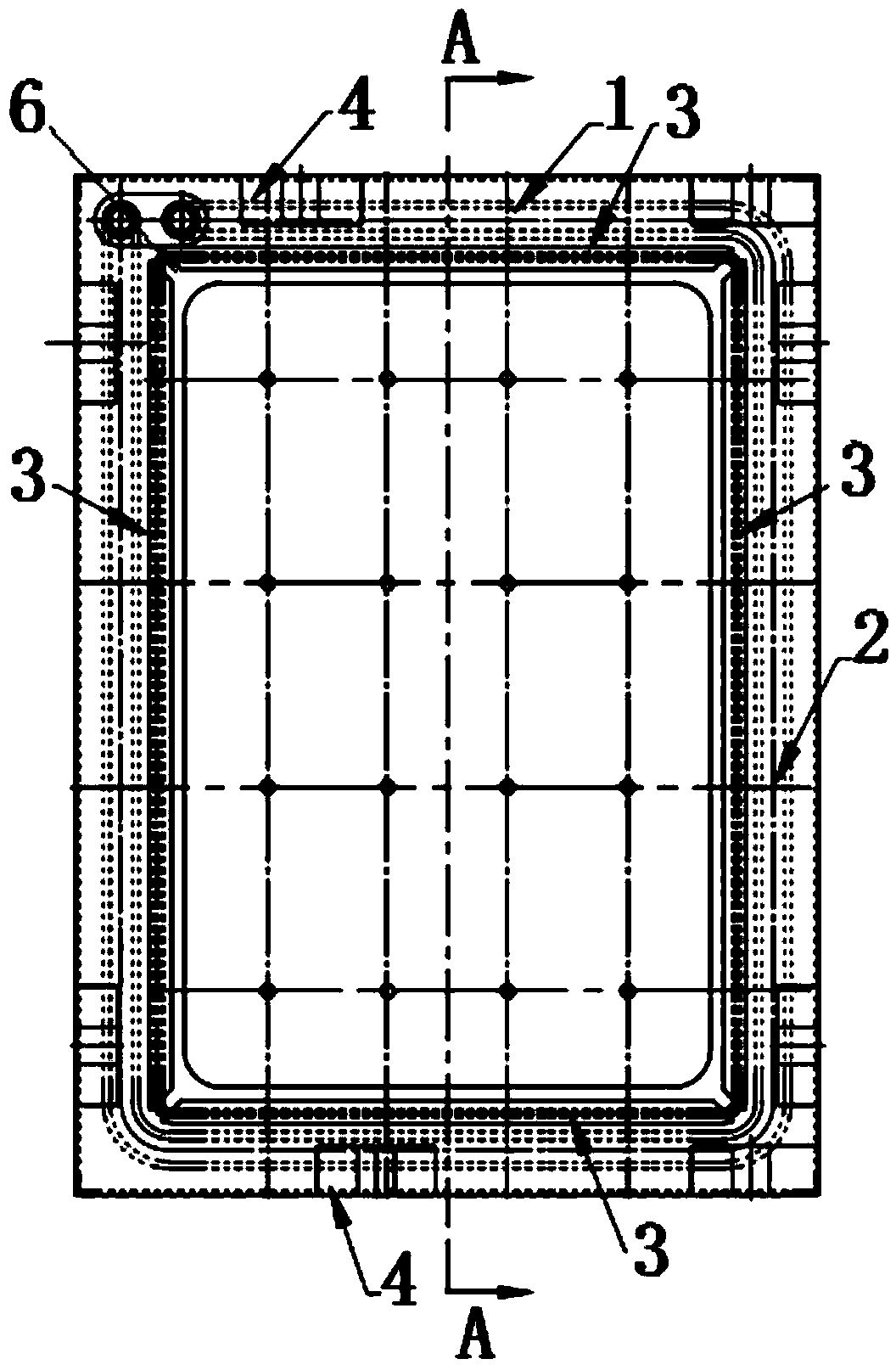

[0039] Such as Figure 1 to Figure 3 As shown, the copper-iron water jacket includes a base body 1, a copper tube 2 is arranged in the base body 1, and the copper tube 2 is connected with a water inlet pipe and a water outlet pipe, and a steel plate frame integrally formed with the base body 1 is arranged in the base body 1; The frame is formed by butting steel plates 3 integrally formed in the base body 1 and the base body 1 , and nails 5 are welded on the steel plates 3 . Not only the iron plate frame can increase the structural strength of the copper-iron water jacket, but also the claw nails 5 welded on the iron plate are firmly combined with the base 1 to ensure the degree of bonding between the steel plate 3 and the base 1 and to ensure that the steel plate 3 and the base 1 have good ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com