On-line integrated monitoring device and method for deep well oil and gas reservoir temperature and pressure

A monitoring device and oil and gas layer technology, applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., can solve problems such as not being able to meet testing needs, and achieve the effect of ensuring sensitivity, accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

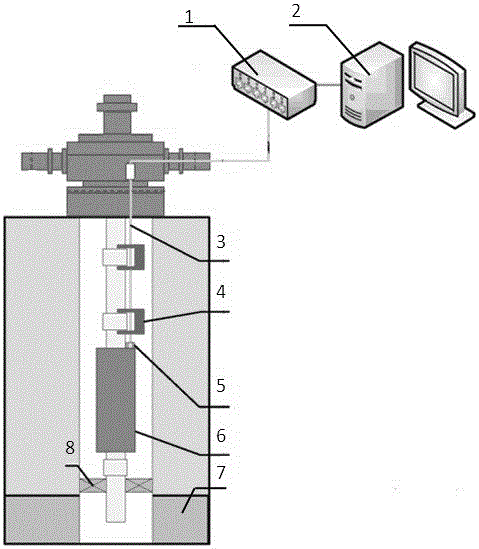

[0037] The present invention is described in more detail below in conjunction with accompanying drawing example:

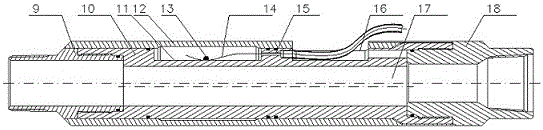

[0038] During the oil and gas collection process of the deep well oil and gas layer 7, the smart tubing 6 designed by the present invention is installed in the downhole near the packer 8 as a part of the oil and gas pipeline, and the rigid stainless steel capillary drawn by the smart tubing 6 is fixed by the fixing device 4 On the oil and gas pipeline, a sealing plug 5 is used to seal between the rigid stainless steel capillary and the smart oil pipe 6 . After the rigid stainless steel capillary is led out of the ground, it is connected to the optical fiber signal modem 1, and the modem 1 transmits the optical fiber signal to the host computer 2 through the serial communication mode to process and obtain the deep well through the special signal processing software developed by the invention. Temperature and pressure information of oil and gas reservoirs.

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com