Production method of hdpe hot-dip galvanized prestressed steel strand for bridge cables

A technology of prestressed steel strand and production method, applied in hot-dip plating process, textile cable, coating and other directions, can solve problems such as urgent research and development, and achieve saving bridge construction materials, good fatigue resistance, economic benefits and social benefits Significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

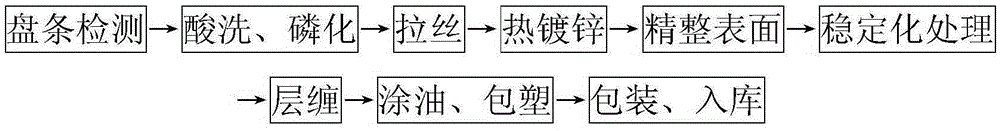

[0019] The production method of the HDPE hot-dip galvanized prestressed steel strand for bridge cables of the present invention is illustrated in conjunction with the accompanying drawings.

[0020] The production method of HDPE hot-dip galvanized prestressed steel strand for bridge cable of the present invention:

[0021] (1) drawing

[0022] Italian RI9 / 1200 wire drawing equipment is adopted. The wire drawing process adopts active stirring lubrication and rotating cooling mold combination technology to improve lubrication conditions, ensure the surface quality of semi-finished steel wire and improve the plasticity and torsion performance of steel wire. Its industrial characteristics are:

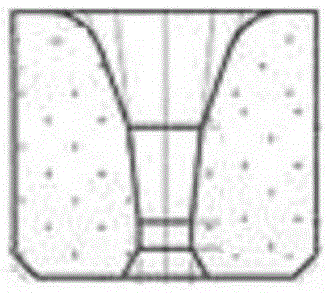

[0023] a. Adopt "small angle + long core" drawing die, working cone angle of drawing die: 8-10°, core length: 28-35mm, such as figure 2 shown.

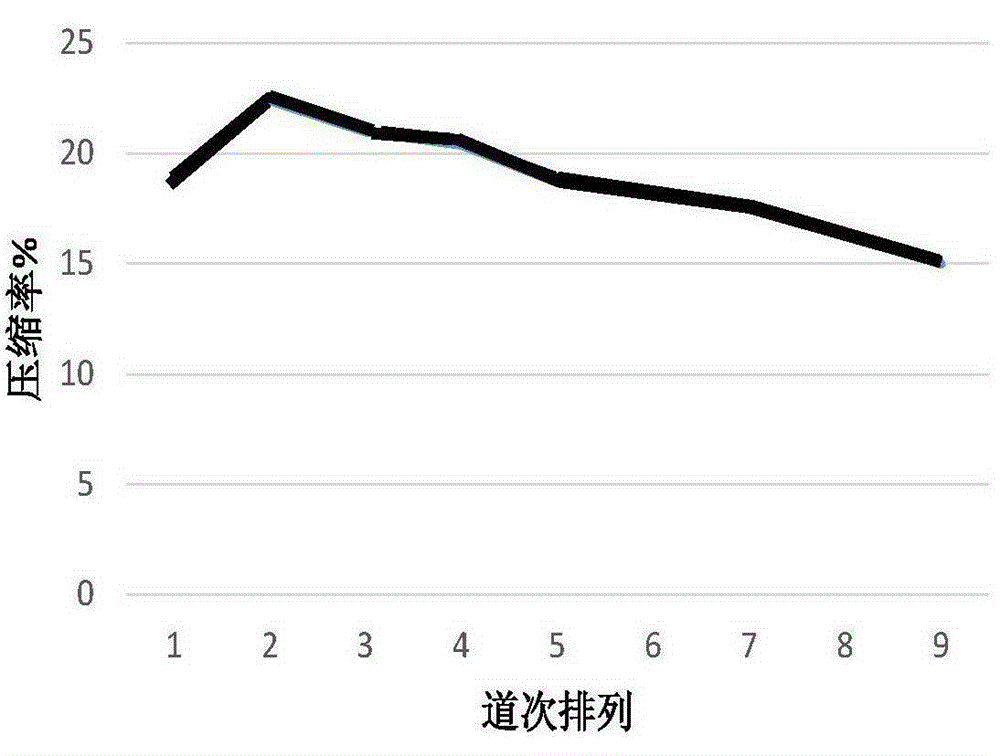

[0024] b. Nine times of continuous drawing, the wire drawing process route with hump-shaped compression ratio distribution is selected, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com