Dyeing cylinder in dyeing assembly line of non-woven fabric

A non-woven fabric and production line technology, applied in the dye vat of non-woven fabric dyeing production line, in the field of non-woven fabric dyeing production line, can solve the problems of wasting heat, affecting the dyeing quality, and easy heat loss of dye vats, etc., to reduce heat loss and ensure Dyeing quality, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

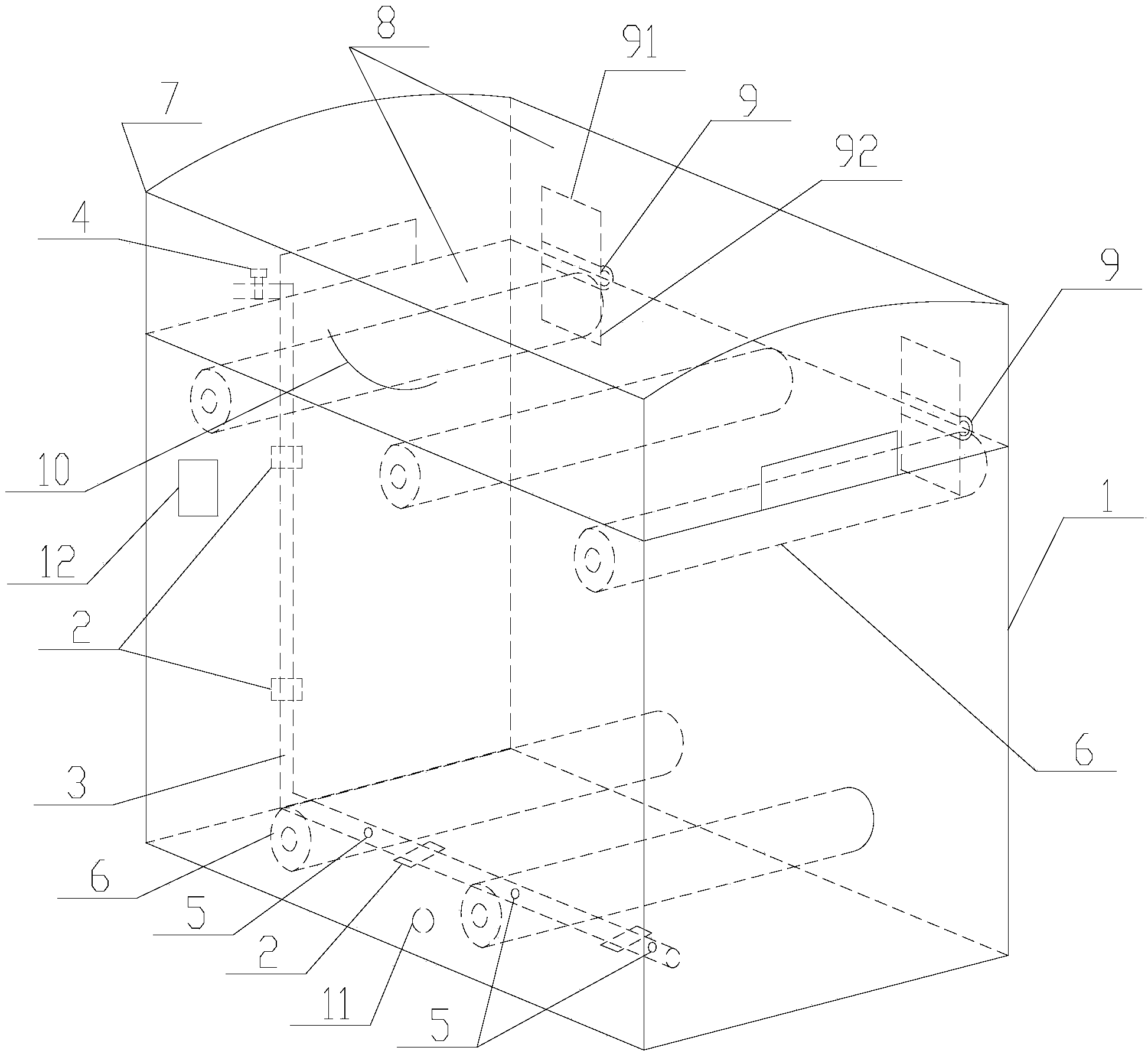

[0016] refer to figure 1 , a dyeing vat of a non-woven fabric dyeing production line according to the present invention, comprising a cylinder body 1, several fixing buckles 2, an aeration pipe 3, a regulating valve 4, several air outlets 5, several guide rollers 6, a protective cover 7, and a heat insulation layer 8. A number of connectors 9, handles 10, discharge ports 11 and thermometers 12, the inner side and inner bottom of the cylinder body 1 are provided with fixing buckles 2, and the fixing buckles 2 are provided with aeration pipes 3 , the aeration pipe 3 is provided with a regulating valve 4 and an air outlet 5, the end of the aeration pipe 3 is provided with an air outlet 5, the cylinder 1 is provided with a guide roller 6, and the cylinder 1 A protective cover 7 that can be opened and closed is installed in cooperation, and the protective cover 7 and the cylinder body 1 are connected to each other by a connecting body 9. The inner top surface and the inner side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com