Steel band continuous copper plating VI

A technology for continuous copper plating of steel strips and steel strips, which is applied in the field of alkaline copper plating, and can solve the problems of high cost and general output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

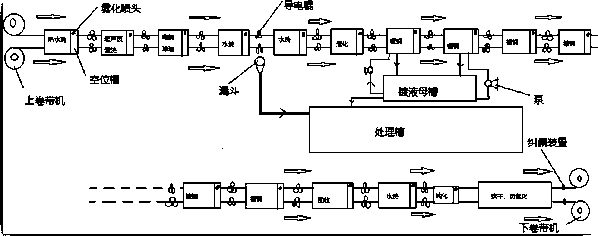

Image

Examples

Embodiment 1

[0014] The process tank in the continuous copper plating of the steel strip adopts a closed isosceles trapezoidal tank with a transparent automatic opening observation window, and the tank body is designed as an isosceles trapezoidal tank body above; There are three transparent observation windows that can be opened automatically; a hydrogen concentration alarm is set above the plating tank, and the probe of the alarm is placed in the coating tank; there are emergency air valves on both sides of the tank; Air pipe; air valve, hydrogen concentration alarm are connected with the controller. During the continuous copper plating production process of the steel strip, hydrogen gas will be precipitated at the same time as the cathode discharges, and a hydrogen enriched area will be formed above the plating tank. The alarm probe will detect the concentration of hydrogen in the plating tank. When the hydrogen concentration reaches or exceeds the preset alarm When the value is reached,...

Embodiment 2

[0016] The mother tank of the plating solution is equipped with a sodium carbonate concentration sensor and a sodium carbonate concentration alarm; the sodium carbonate concentration sensor is connected to the sodium carbonate concentration alarm; the sodium carbonate concentration alarm is connected to the controller; connected to the filter pump. The sodium carbonate sensor detects the concentration of sodium carbonate. When the sodium carbonate content exceeds 75g / L, the sodium carbonate alarm sends the signal to the controller, and the controller controls the filter pump to pour the plating solution in the plating solution mother tank into the treatment tank. Sodium carbonate is crystallized by the refrigerator in the treatment tank, and then the plating solution is sent back to the mother tank of the plating solution, and the mother tank of the plating solution returns the plating solution to the plating tank. It avoids the decrease of the current efficiency of the platin...

Embodiment 3

[0018] An infrared probe, a control cabinet, a motor and a deviation-correcting roller are arranged between the continuous copper-plating drying of the steel strip and the coiling machine. The infrared probe is connected to the control cabinet; the control cabinet is connected to the motor; the motor is connected to the deviation-correcting roller. When in use, the infrared probe senses the position of the steel strip, measures the distance from the edge of the steel strip, and transmits the signal to the control cabinet at the same time. The tape machine then completes the tape work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com