Intelligent comprehensive environment-friendly carbonizing device using waste straw resources

A technology for waste straw and resources, which is applied in the field of intelligent comprehensive environmental protection charcoal-making equipment for waste straw resources, can solve the problem of high operating cost, and achieve the effects of improving the working environment, low cost and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

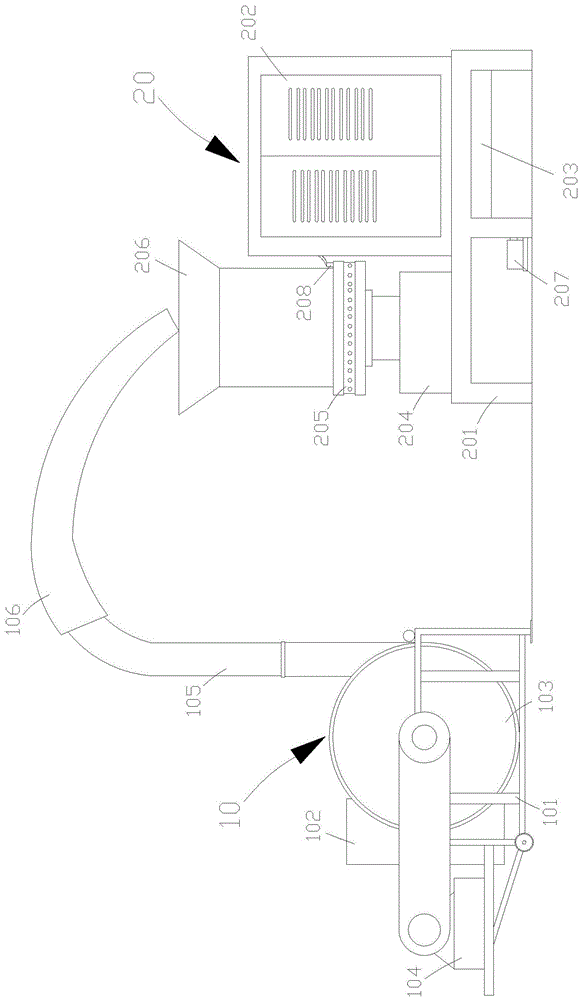

[0015] Such as figure 1 As shown, an intelligent comprehensive environmental protection charcoal production device for waste straw resources includes a crushing mechanism 10 and a charcoal making mechanism 20. The final material directly enters the charcoal making mechanism 20 for charcoal making, reducing the storage and transportation links of intermediate materials;

[0016] The crushing mechanism 10 includes a base 101, on which a crushing chamber 102 is arranged, a blower fan 103 is installed at the outlet of the crushing chamber 102, and a motor 104 is arranged at one end of the base 101, the motor 104 is connected with the blower fan 103, and the blower fan 103 is connected with an outlet Material pipe 105, the discharge pipe head 106 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com