Method for preparing high-hardness heat-resisting cable sheath material

A cable sheath, high hardness technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of inability to protect the wire, cannot be used, damage to the protective layer of the cable, etc., to achieve good physical and mechanical properties, easy compound mixing, The effect of improving compound properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

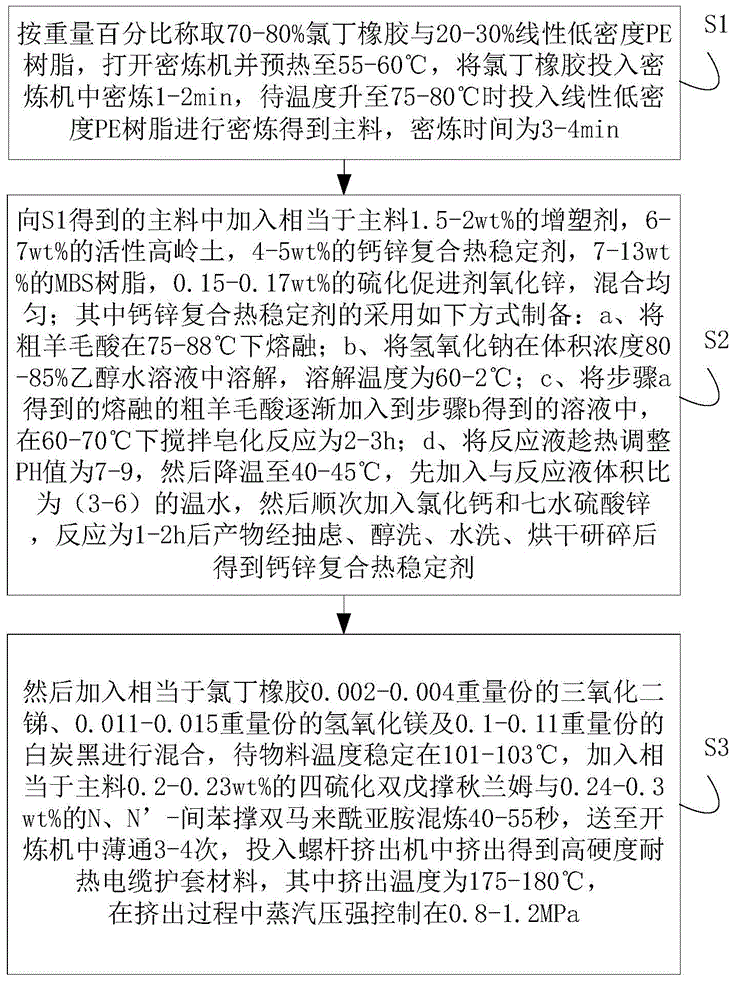

[0016] Reference figure 1 , The method for preparing a high-hardness and heat-resistant cable sheath material provided by the present invention includes the following steps:

[0017] S1. Weigh 70-80% neoprene rubber and 20-30% linear low-density PE resin according to weight percentage, turn on the internal mixer and preheat to 55-60℃, put the neoprene rubber in the internal mixer for mixing 1 -2min, when the temperature rises to 75-80℃, add linear low-density PE resin for banburying to obtain the main material, banburying time is 3-4min;

[0018] S2. Add 1.5-2wt% plasticizer, 6-7wt% active kaolin, 4-5wt% calcium-zinc composite heat stabilizer, 7-13wt% MBS resin to the main material obtained from S1 , 0.15-0.17wt% of vulcanization accelerator zinc oxide, mixed uniformly; wherein the calcium-zinc composite heat stabilizer is prepared as follows: a. Melt crude lanolin at 75-88°C; b. Put sodium hydroxide in Dissolve in 80-85% ethanol aqueous solution with a volume concentration of 60...

Embodiment 1

[0021] In this embodiment, a method for preparing a high-hardness and heat-resistant cable sheath material includes the following steps:

[0022] S1. Weigh 77% chloroprene rubber and 33% linear low-density PE resin according to weight percentage, turn on the internal mixer and preheat to 55℃, put the chloroprene rubber in the internal mixer for 2 minutes, wait for the temperature to rise to 75 Add linear low-density PE resin for banburying at ℃ to obtain the main material, the banburying time is 3min;

[0023] S2. Add 1.7wt% plasticizer, 7wt% active kaolin, 4.2wt% calcium-zinc composite heat stabilizer, 12wt% MBS resin, 0.15wt% vulcanization to the main material obtained from S1. Promoter zinc oxide, mixed evenly; among them, the calcium-zinc composite heat stabilizer is prepared as follows: a. Melt crude lanolin at 85℃; b. Dissolve sodium hydroxide in 80% ethanol aqueous solution by volume concentration. The temperature is 71°C; c. The molten crude lanolin obtained in step a is g...

Embodiment 2

[0026] In this embodiment, a method for preparing a high-hardness and heat-resistant cable sheath material includes the following steps:

[0027] S1. Weigh 80% neoprene rubber and 20% linear low-density PE resin according to weight percentage, turn on the internal mixer and preheat it to 57℃, put the neoprene rubber in the internal mixer for banburying for 2 minutes, and wait for the temperature to rise to 75 Add linear low-density PE resin for banburying at ℃ to obtain the main material, and the banburying time is 3min;

[0028] S2. Add 1.7wt% plasticizer, 6.5wt% activated kaolin, 5wt% calcium-zinc composite heat stabilizer, 8wt% MBS resin, 0.17wt% vulcanization to the main material obtained from S1. Promoter zinc oxide, mixed uniformly; among them, the calcium-zinc composite heat stabilizer is prepared as follows: a. Melt crude lanolin at 76°C; b. Dissolve sodium hydroxide in an aqueous ethanol solution with a volume concentration of 82% The temperature is 70°C; c. The molten cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com