Catalyst charging method in neodymium polybutadiene rubber polymerization processes

A technology of polybutadiene rubber and feeding method, applied in the field of rubber production, can solve the problems of large fluctuation of reaction temperature, high Mooney, unsatisfactory reaction effect, etc., and achieves stable temperature and stable product quality, which is beneficial to Mooney. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0021] Embodiment 2 (new method):

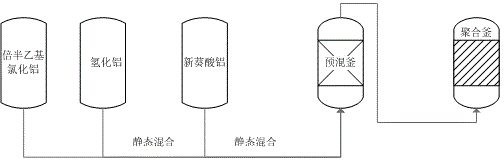

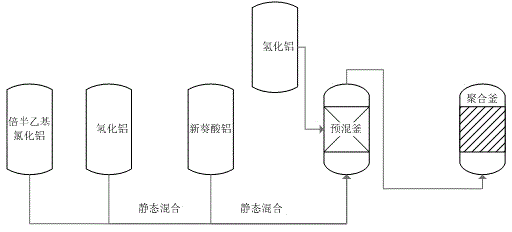

[0022] (1) Mix the mixed catalyst composed of sesquiethylaluminum chloride (referred to as sesquialuminum), diisobutylaluminum hydride (abbreviated as aluminum hydride), and neodymium neodecanoate in a certain proportion through a static mixer for ternary Aging, aging time 25-35min, temperature 25°C-35°C; (2) After aging, the mixed catalyst and butyl oil enter the premixing tank for buffering and then enter the polymerization tank to participate in the polymerization reaction. The pressure of the polymerization tank is 0.35-0.45MPa , The temperature of the first polymerization tank is 60°C-75°C, and the temperature of the remaining polymerization tanks is 60-90°C; Butyl oil includes butadiene and solvent oil, and the solvent oil is n-hexane; (3) At the same time, partially hydrogenated diisobutyl Aluminum (referred to as single-added aluminum) is directly added from the middle and lower part of the premixing tank without aging, and enters th...

Embodiment 3

[0030] Embodiment 3 (new method):

[0031] The amount of mixed catalyst used in ternary aging remains unchanged, the formula of monohydrogenated diisobutylaluminum (abbreviated as mono-added aluminum) and neodecanoic acid neodymium is adjusted to HAL / Nd (mol / mol) 1.8:1, and the rest are the same as in the examples 2 is the same. After testing, the Mooney is 47, and the temperature fluctuation is between 66°C and 75°C.

Embodiment 4

[0032] Embodiment 4 (new method):

[0033] The amount of mixed catalyst used in ternary aging remains unchanged, the formula of monohydrogenated diisobutylaluminum (referred to as mono-added aluminum) and neodecanoic acid neodymium is adjusted to HAL / Nd (mol / mol) 4:1, and the rest are the same as in the examples 2 is the same. It reflects that the trend basically tends to be stable, and the temperature fluctuation is between 70°C±2°C. Mooney 44, the response state tends to be stable with little fluctuation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com