Metal rhodium-1,2-di(diphenyl phosphine)ethane complex crystal and preparation method thereof

A technology of diphenylphosphine and complexes, which is applied in the field of metal rhodium-1,2-bisethane complex crystals and its preparation, which can solve the problems of cumbersome process and achieve the effect of simple and easy preparation method and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of metallic rhodium-1,2-bis(diphenylphosphine)ethane complex crystal comprises the following steps:

[0022] 1) Prepare 0.8-1.2g / L rhodium chloride aqueous solution, then add stannous chloride to it, place the solution in a 45-55°C water bath for 40-60min, and then place it at room temperature to cool;

[0023] 2) Add 1,2-bis(diphenylphosphine)ethane tetrahydrofuran solution to the above system to obtain light yellow precipitate; the 1,2-bis(diphenylphosphine)ethane tetrahydrofuran solution The concentration is 0.08-0.12g / L;

[0024] 3) Add dichloromethane to the above system to form layers, then volatilize the solvent and generate products at the phase interface.

[0025] The volume ratio of the rhodium chloride aqueous solution in step 1) to the tetrahydrofuran solution of 1,2-bis(diphenylphosphine)ethane in step 2) is 1:(0.8-1.2).

[0026] In step 1), the molar ratio of stannous chloride to rhodium chloride is 3.5-4.5:1.

[0027] The volume ...

Embodiment 1

[0030] Prepare 5ml of 1g / L rhodium chloride solution, add stannous chloride at a molar ratio of 4:1 (the molar ratio of stannous chloride to rhodium chloride is 4:1), put it in a water bath at 50°C for 1 hour, and the solution changes from The dark yellow turns into deep purple, and then left to cool at room temperature. Add 5ml of tetrahydrofuran solution of 1,2-bis(diphenylphosphine)ethane with a concentration of 0.1g / L to form a pale yellow precipitate;

[0031] Add 5ml of dichloromethane to the above system, layered into two phases, let the solvent evaporate until the volume of the system is 10ml, it can be seen that crystals are generated between the layered two phases.

Embodiment 2

[0033] Take out the crystal, carry out corresponding crystal structure analysis, the result is as follows:

[0034] Table 1:

[0035]

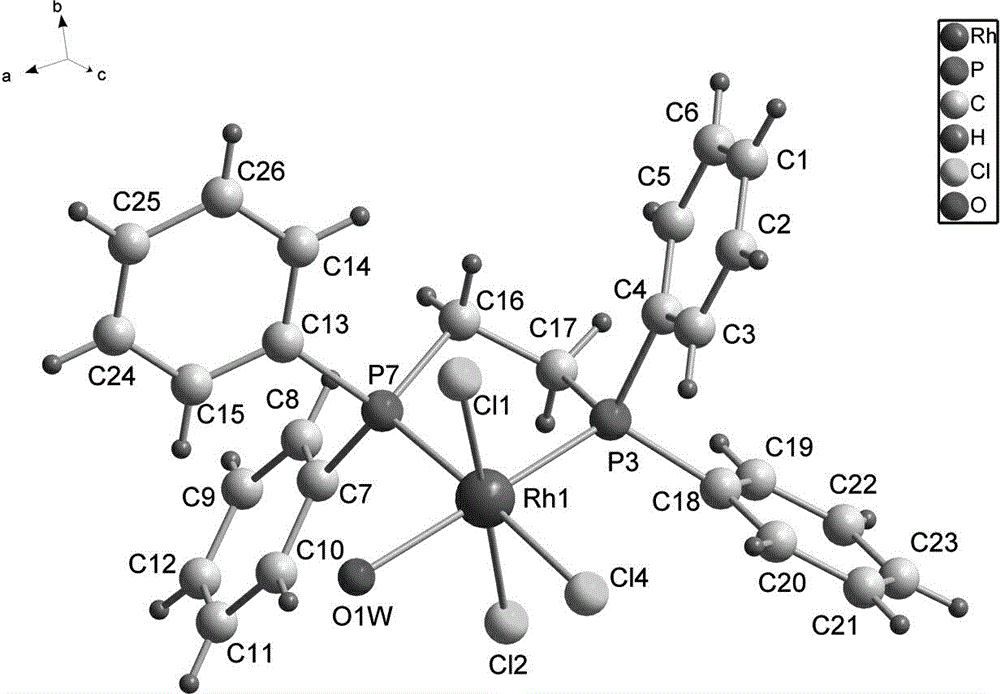

[0036] figure 1 It is the molecular structure and atomic label of the crystal obtained in the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com