Method for treating cyanogen-containing copper-containing electroplating wastewater by electrolysis and recycling copper

A technology of electrolytic treatment and copper electroplating, which is applied in the direction of water/sewage treatment, metallurgical wastewater treatment, chemical instruments and methods, etc., can solve the problems of difficult reuse of effluent, excessive discharge, complicated process, etc., and achieve easy precipitation separation, electrolysis The effect of improving efficiency and increasing the reaction speed of cyanide breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

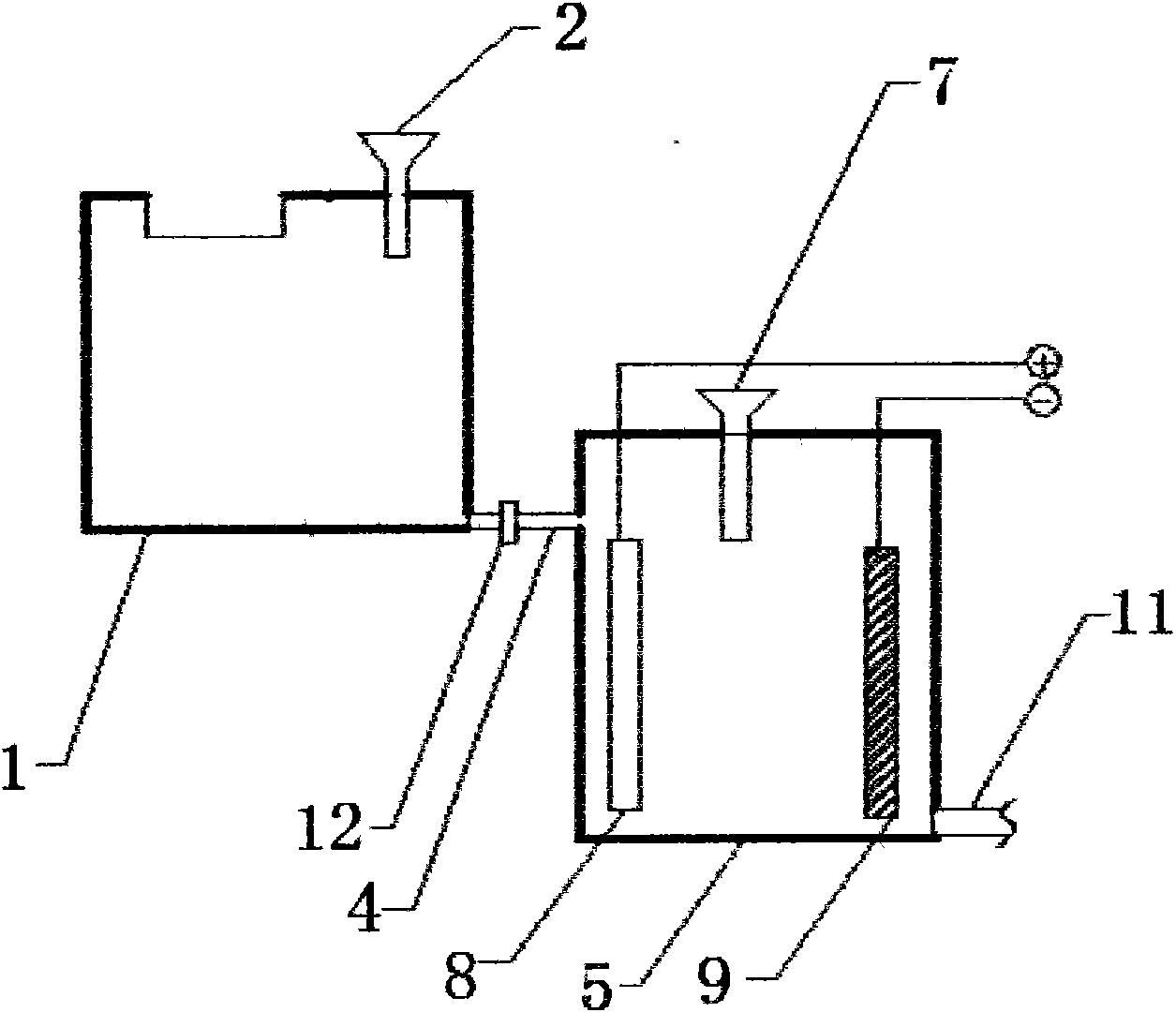

Embodiment 1

[0042] The method for electrolytic treatment of electroplating wastewater containing cyanide and copper is as follows: before electrolytic treatment, electroplating wastewater with concentrations of cyanide and copper of 2600 mg / L and 2200 mg / L respectively is put into reaction tank 1; Sodium; measured OH in wastewater - The concentration is 3.5 times of the CN concentration, and the copper hydroxide precipitate and filtrate are filtered; the above-mentioned filtrate flows into the electrolytic cell 5 through the pipeline 4 as the electrolyte, and the pipeline is provided with a shut-off valve 12; simultaneously, the hydrogen in the reaction tank 1 is oxidized Copper recovery; start electrolysis, add mesoporous granular activated carbon and NaCl through the second hopper 7 at the upper end of the electrolytic cell 6 according to the ratio of 0.06% and 0.4% of the electrolyte, conduct direct current electrolysis, and strengthen between the positive and negative poles 8 and 9 Th...

Embodiment 2

[0044] Before the electrolytic treatment, the concentration of cyanide and copper is respectively 5800mg / L and 3100mg / L electroplating waste water is put into reaction tank 1 in cyanide and copper concentration respectively; Add sodium hydroxide through the hopper 2 of reaction tank 1 top; Measure the wastewater Medium OH - Concentration is CN - 3 times of the concentration, filter to get copper hydroxide precipitate and filtrate; the above-mentioned filtrate flows into the electrolytic cell 5 through the pipeline 4 as electrolyte, and the pipeline is provided with a shut-off valve 12; simultaneously, the copper hydroxide in the reaction tank 1 is reclaimed; Start electrolysis, add mesoporous granular activated carbon and NaCl through the second hopper 7 at the upper end of the electrolytic cell 6 at a ratio of 0.1% and 0.5% of the electrolytic solution, conduct direct current electrolysis, and strengthen the electrostatic field 200V between the positive and negative poles 8 a...

Embodiment 3

[0046] Before the electrolytic treatment, put the electroplating wastewater with cyanide and copper concentrations of 930mg / L and 817mg / L respectively into the reaction tank 1; add sodium hydroxide through the hopper 2 at the upper end of the reaction tank 1; measure the OH in the wastewater - Concentration is CN - 3.7 times of the concentration, filter to obtain copper hydroxide precipitate and filtrate; the above-mentioned filtrate flows into the electrolytic cell 5 as electrolyte through the pipeline 4, and the pipeline is provided with a shut-off valve 12; simultaneously the copper hydroxide in the reaction tank 1 is reclaimed; Start electrolysis, add mesoporous granular activated carbon and NaCl by the ratio of 0.04% and 0.4% of the electrolytic solution through the second hopper 7 at the upper end of the electrolytic cell 6, conduct direct current electrolysis, and strengthen the electrostatic field 150V between the positive and negative poles 8 and 9 / cm, the direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com