Parking mechanism for all terrain vehicles

A technology for parking mechanism and all-terrain vehicle, which is applied to bicycle accessories, bicycle brakes, hydraulic brake transmission devices, etc. range, increase parking safety, and eliminate potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

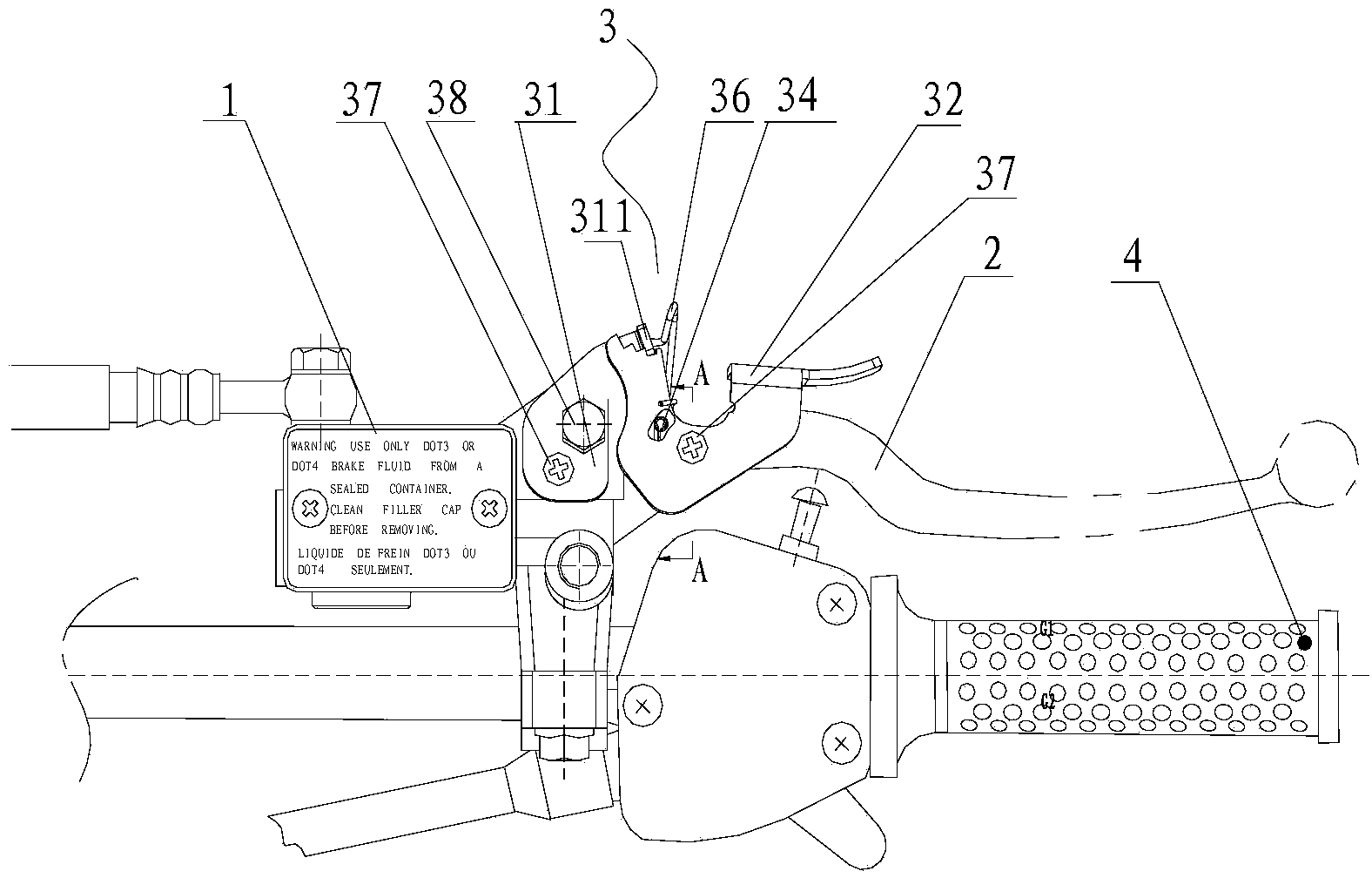

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] like figure 1 As shown, when the parking mechanism is not installed, the braking process of the front brake is as follows: hold the handle with your hand, pull the brake handle 2 downward with your fingers, and the brake handle 2 rotates around the handle bolt 38. During the rotation, , the brake handle 2 pushes the piston in the brake pump 1, and the piston compresses the brake fluid to realize the braking process.

[0035] After increasing the parking mechanism of the present invention, as Figure 2 to Figure 6 As shown, a parking mechanism for an all-terrain vehicle includes a brake pump 1 and a brake handle 2 connected to the brake pump 1, and also includes a parking device 3 that can keep the braking system in a parking state. The parking device 3 includes a limiting plate 31 , which is fixed on the brake pump 1 through screws 37 and handle bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com