Trolley device for automatic replacement of machine tool accessories

An automatic replacement and attachment technology, which is applied to positioning devices, metal processing machinery parts, large fixed members, etc., can solve the problems of quantity limitation, occupancy, high manufacturing cost of the head warehouse, etc., and achieve good results and safe and reliable actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

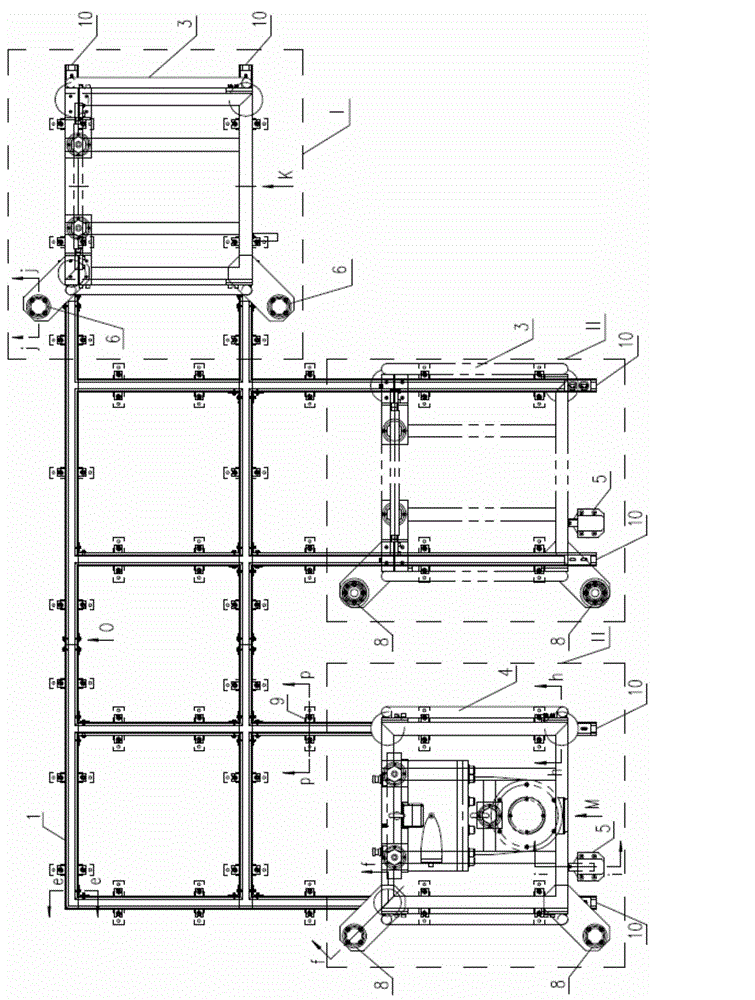

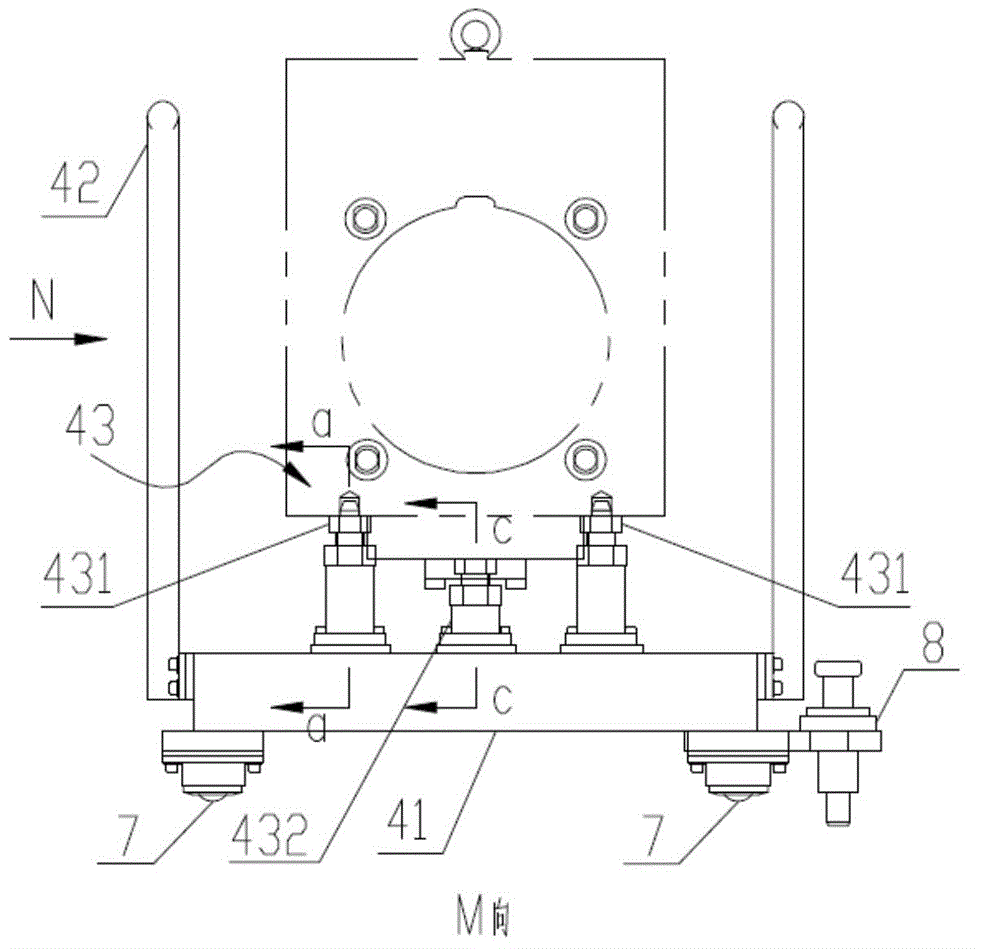

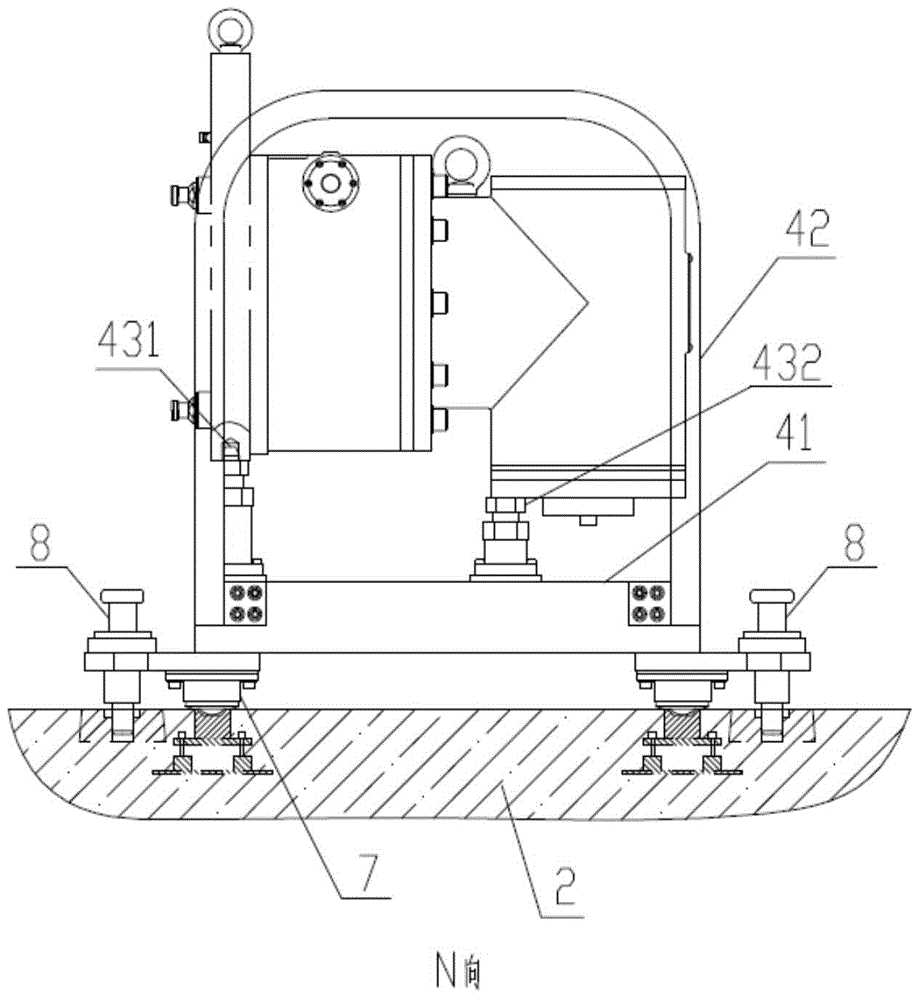

[0040] Such as figure 1 As shown, a machine tool accessory automatic replacement cart device according to an embodiment of the present invention includes a guide rail 1, an accessory removal cart 3, an accessory installation cart 4, an exchange station I, and a parking lot II. The guide rail 1 is fixed to the foundation 2 of the machine tool by casting (see image 3 )in. The guide rail 1 can be spliced, and the corners are connected with the L-shaped angle iron connecting block 101 (see Picture 11 ), the straight line is connected by the straight line connecting block 102 (see Image 6 ). A stop 10 is installed at the end of the guide rail 1, and the stop 10 can prevent the accessory disassembly cart 3 or the accessory installation cart 4 from sliding out of the guide rail 1. Both the accessory removal cart 3 and the accessory installation ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com