Great pressure-down sector section equipment

A sector-shaped, heavy-reduction technology, applied in the field of metallurgical continuous casting equipment, can solve problems such as the deterioration of the internal quality of the casting billet, and achieve the effects of a wide reduction range, easy single-piece control, and high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

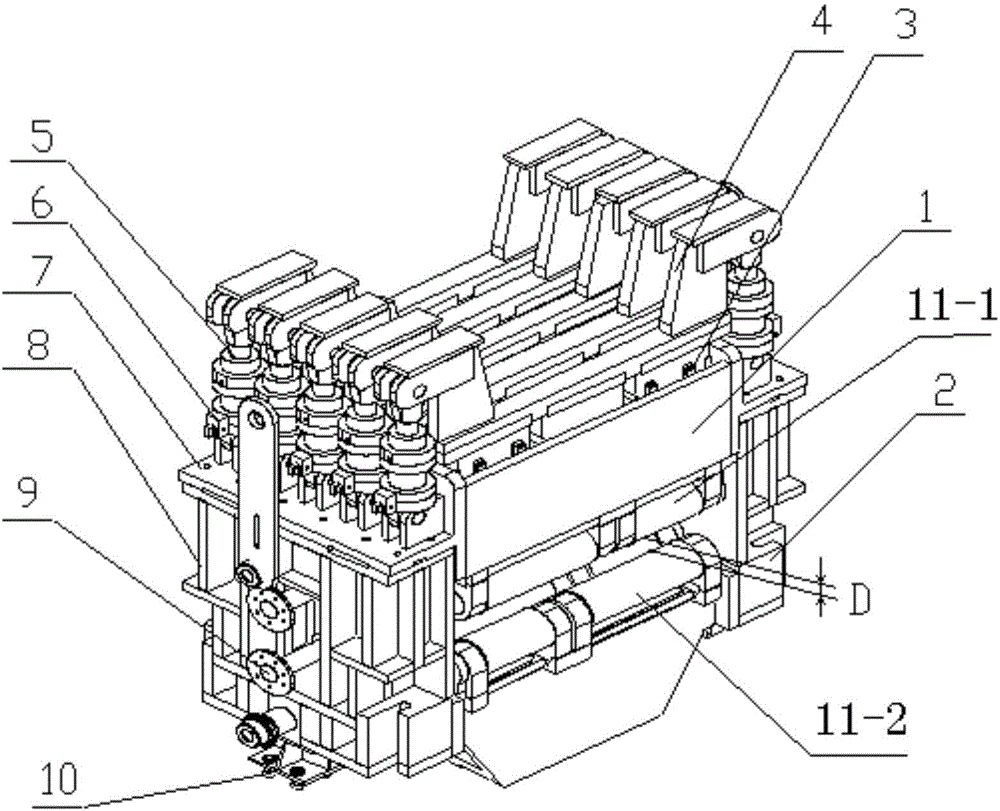

[0009] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] Referring to the accompanying drawings, a heavy-duty lower segment equipment includes an inner arc frame assembly and an outer arc frame assembly; in the inner arc frame assembly, each first roller 11-1 is fixed on a corresponding individual movable beam 4 , the movable beam 4 is connected with the inner arc frame 1 through the hydraulic cylinder 5 hinged at both ends, the inner arc frame 1 is provided with an inner arc frame guide plate 3, the hydraulic cylinder 5 is connected with a displacement control and pressure system 6, and the independent movable beam 4 With the rollers sliding up and down between the guide plates 3 of the inner arc frame with the synchronous expansion and contraction of the hydraulic cylinders 5 at both ends, the up and down position adjustment of each roller is realized. The displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com