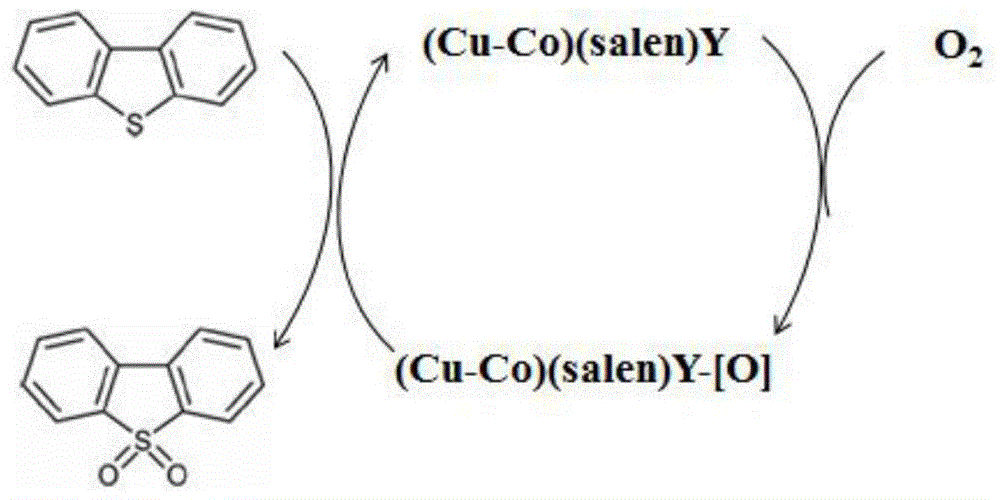

Molecular sieve supported Cu-Cp Schiff base complex, and preparation method and application thereof

A molecular sieve and Schiff base technology, applied in the field of gasoline desulfurization, can solve the problems of poor industrial practicability, cumbersome synthesis steps, and complicated preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106](1) Preparation of Schiff base-type salen ligand: Weigh salicylaldehyde and ethylenediamine at a molar ratio of 2:1 under normal temperature and pressure, dissolve them in 20mL and 30mL ethanol respectively, and add the salicylaldehyde solution into a three-necked flask ethylenediamine solution was added dropwise thereto, stirred at 50°C for 2h, vacuum filtered after standing at room temperature, the filter cake was washed with ethanol, recrystallized twice with ethanol, and vacuum-dried at 60°C for 12h;

[0107] (2) Synthesis of (Cu-Co)Y bimetallic ion-exchange molecular sieves: Weigh 3.5 g of NaY molecular sieves activated at 500 °C for 4 h, 2 Under protection, add 0.05mol / L Cu(Ac) respectively 2 ·H 2 O with 0.05mol / L Co(Ac) 2 4H 2 In 100mL aqueous solution of O, reflux and stir at 90°C for 24h, filter and wash the filter cake with distilled water at about 60°C until it is colorless, and vacuum-dry at 110°C for 6h to obtain brown ion-exchanged molecular sieve (Cu-Co...

Embodiment 2

[0110] The method used in this embodiment is the same as that of Example 1, the difference is only that Cu(Ac) in step (2) 2 ·H 2 The concentration of O is 0.1mol / L and Co(Ac) 2 4H 2 The concentration of O is 0.1 mol / L.

Embodiment 3

[0112] The method used in this embodiment is the same as that of Example 1, the difference is only that Cu(Ac) in step (2) 2 ·H 2 The concentration of O is 0.03mol / L and Co(Ac) 2 4H 2 The concentration of O is 0.07mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com