Acrylic resin composition

A technology of acrylic resin and acrylic oligomer, which is applied in the direction of non-polymer organic compound adhesives, adhesive types, polyurea/polyurethane adhesives, etc., which can solve the problem of increasing crimping procedures, reducing workability, and difficult Manage issues such as resin layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

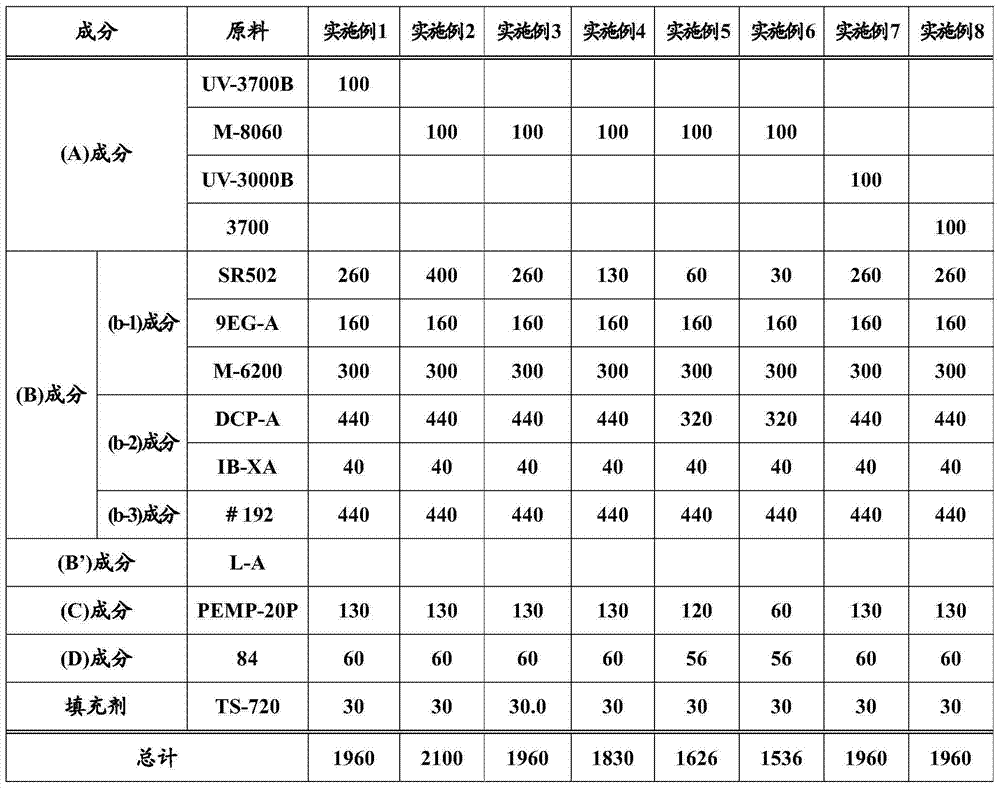

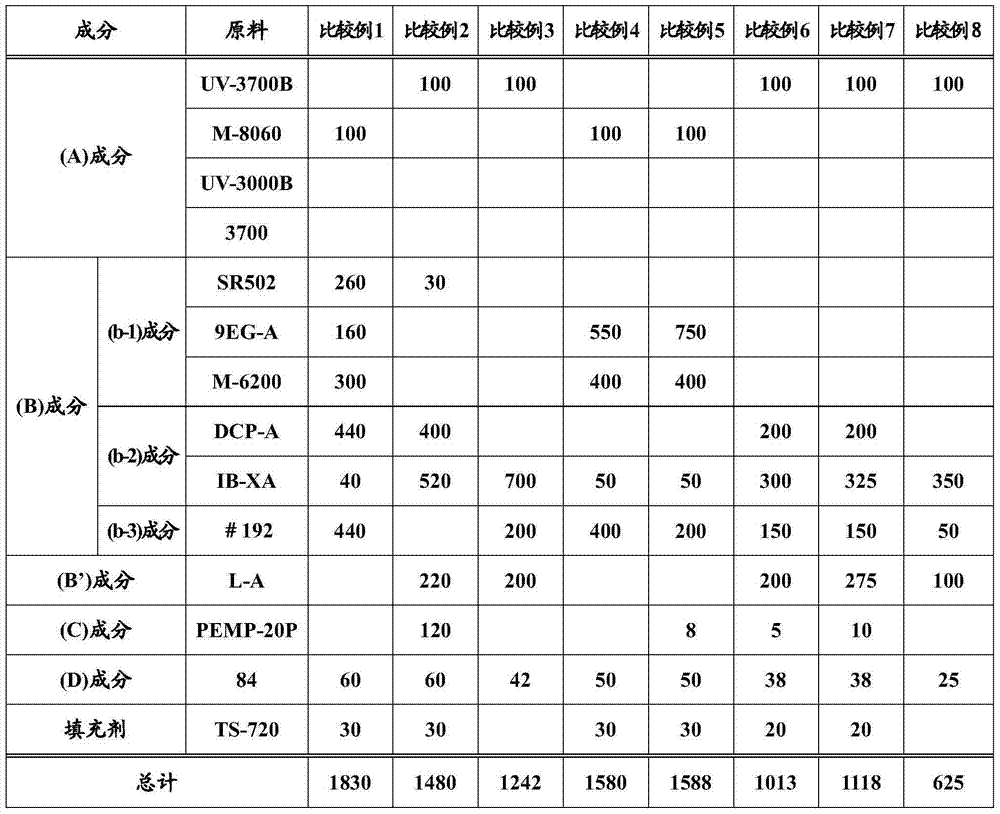

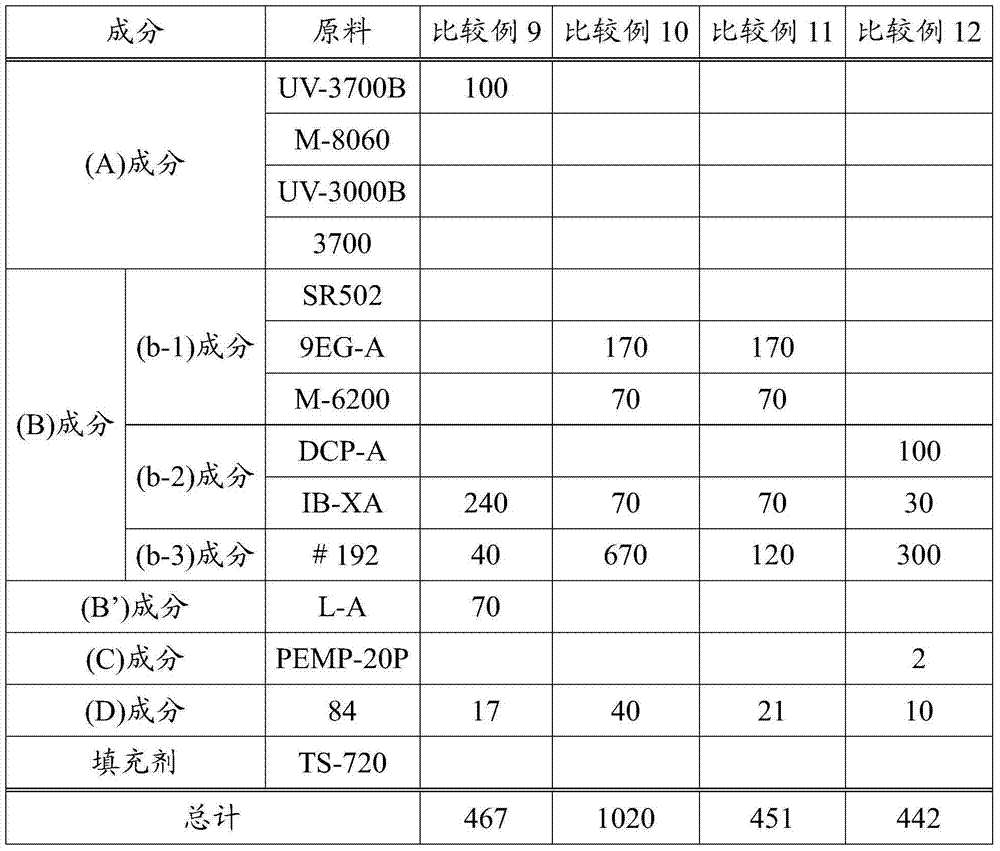

Embodiment 1~8 and comparative example 1~12

[0055] In order to prepare the compositions of Examples 1-8 and Comparative Examples 1-12, the following components were prepared.

[0056] (A) Component: Acrylic oligomer

[0057] ・Polyether-based urethane acrylate (Ultraviolet UV-3700B manufactured by Nippon Gosei Chemical Industry Co., Ltd.: viscosity at 60°C: 30,000 to 60,000 mPa·s)

[0058] ・Polyester acrylate (ARONIX M-8060 Toagosei Co., Ltd.: viscosity at 25°C: 5,000 to 12,000 mPa·s)

[0059] ・Polyester-based urethane acrylate (UV-3000B manufactured by Nippon Gosei Chemical Industry Co., Ltd.: viscosity at 60°C: 45,000 to 65,000 mPa·s)

[0060] ・Bisphenol A type epoxy acrylate (manufactured by Ebecryl 3700 DAICEL-CYTEC Co., Ltd.: viscosity at 60°C is 4,300 mPa·s, viscosity at 25°C is 5000 mPa·s or more)

[0061] (B) Component: Acrylic monomer

[0062] (b-1) Component: polyether and / or polyester acrylic monomer

[0063] ・Ethoxylated (9) trimethylolpropane triacrylate (SR502 manufactured by Sartomer: viscosity at 25° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com