Lead-acid battery container formation technology

A lead-acid battery, internalization technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery, etc., can solve a lot of acid mist and other problems, achieve the effect of simplifying operation, reducing environmental pollution, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

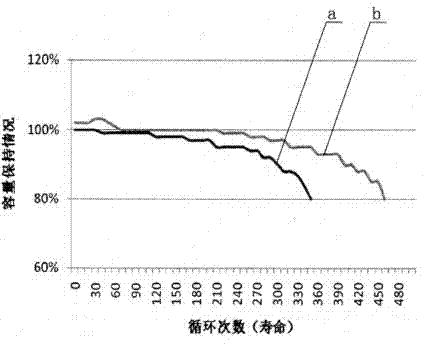

Examples

Embodiment 1

[0039] A kind of internal formation technology of lead-acid storage battery, comprises the following steps:

[0040] Adding acid and standing still: Install the one-way sealing valve to the lead-acid battery, then add acid to the valve-controlled sealed lead-acid battery, add the electrolyte sulfuric acid quantitatively according to the volume of the separator saturation of 100%, and the battery after adding acid Cool the water bath to 35°C, let it stand for 2 hours, then cover the safety valve, and glue the battery cover, which is ultrasonically welded;

[0041] Connect the obtained accumulator to the charger for internalization, and the internalization steps are shown in Table 1;

[0042] The first stage of internalization is step 1-8; the second stage of internalization is step 9-14; the third stage of internalization is step 15-31; wherein, the density of sulfuric acid in the electrolyte is 1.32g / cm 3Adding mass fraction of 0.7% anhydrous sodium sulfate and 0.07% stannous...

Embodiment 2

[0045] A kind of internal formation technology of lead-acid storage battery, comprises the following steps:

[0046] Add acid and stand still: add acid to the lead-acid battery, add sulfuric acid in the electrolyte solution quantitatively according to the volume of the separator saturation 100%, cool the battery water bath to 45°C after acid addition, let stand for 3 hours, and then cover the safety valve. Bond the battery cover, and the battery cover is ultrasonically welded;

[0047] Connect the obtained accumulator to the charger for internalization, and the internalization steps are shown in Table 1;

[0048] The first stage of internalization is step 1-8; the second stage of internalization is step 9-14; the third stage of internalization is step 15-31; wherein, the density of sulfuric acid in the electrolyte is 1.35g / cm 3 Adding mass fraction of 1% anhydrous sodium sulfate and 0.1% stannous sulfate into the sulfuric acid; the temperature of the storage battery is me...

Embodiment 3

[0051] A kind of internal formation technology of lead-acid storage battery, comprises the following steps:

[0052] Adding acid and standing still: Install the one-way sealing valve to the lead-acid battery, then add acid to the valve-controlled sealed lead-acid battery, add the electrolyte sulfuric acid quantitatively according to the volume of the separator saturation of 100%, and the battery after adding acid Cool the water bath to 55°C, let it stand for 4 hours, then cover the safety valve, and glue the battery cover, and the battery cover is bonded with epoxy resin solution;

[0053] Connect the obtained accumulator to the charger for internalization, and the internalization steps are shown in Table 1;

[0054] The first stage of internalization is step 1-8; the second stage of internalization is step 9-14; the third stage of internalization is step 15-31; wherein, the density of sulfuric acid in the electrolyte is 1.37g / cm 3 Adding mass fraction of 1.05% anhydrous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com