Grooved semiconductor device and manufacturing method thereof

A technology of semiconductors and conductive semiconductors, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as high forward voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

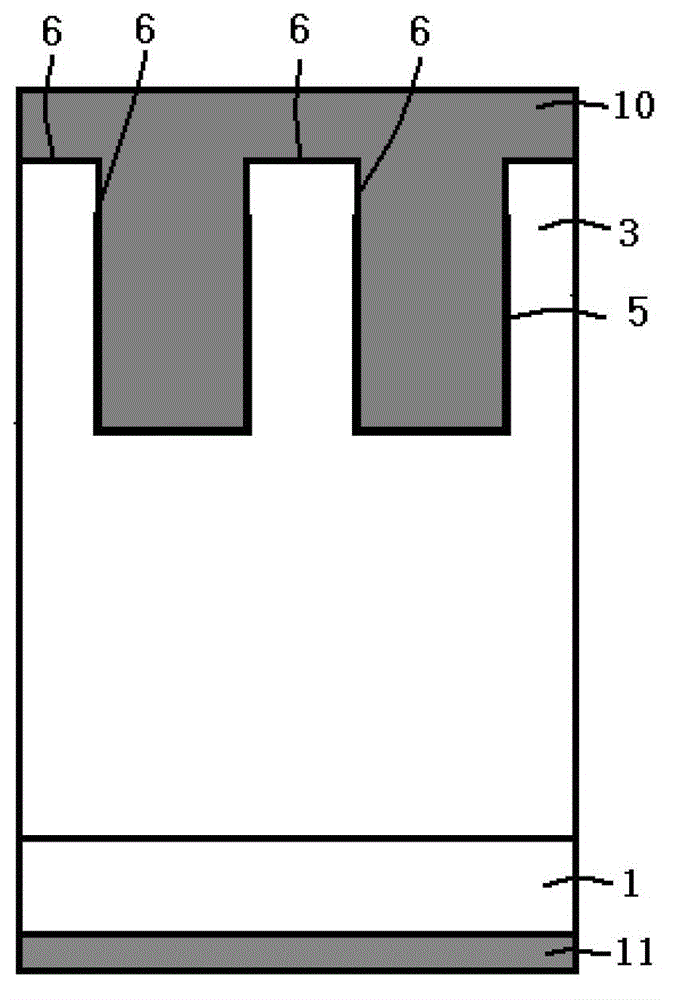

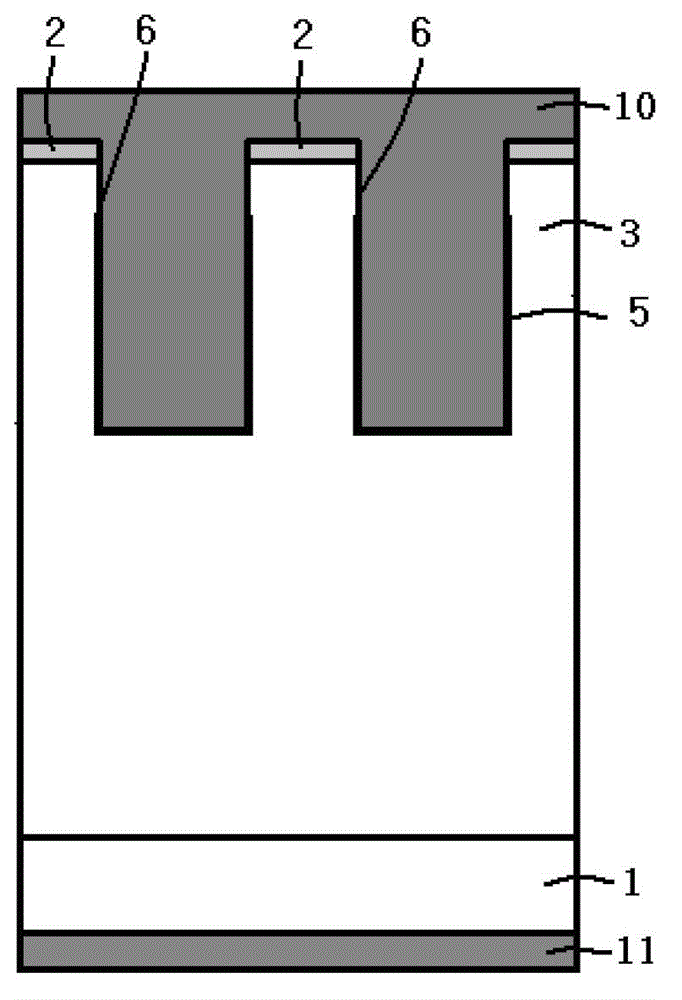

[0027] figure 1 It is a sectional view of a trench semiconductor device of the present invention, combined below figure 1 The semiconductor device of the present invention will be described in detail.

[0028] A trench semiconductor device, comprising: a substrate layer 1, which is an N conductivity type semiconductor silicon material, and the doping concentration of phosphorus atoms is 1E19 / CM 3 , on the lower surface of the substrate layer 1, the electrodes are drawn out through the lower surface metal layer 11; the first conductive semiconductor material 3, located on the substrate layer 1, is a semiconductor silicon material of N conductivity type, and the doping concentration of phosphorus atoms is 1E16 / CM 3 , there is a region doped with a high concentration of impurities near its upper surface; Schottky barrier junction 5, located on the inner wall of the trench, is a silicide formed by semiconductor silicon material and barrier metal, and the trench spacing is 0.5um; ...

Embodiment 2

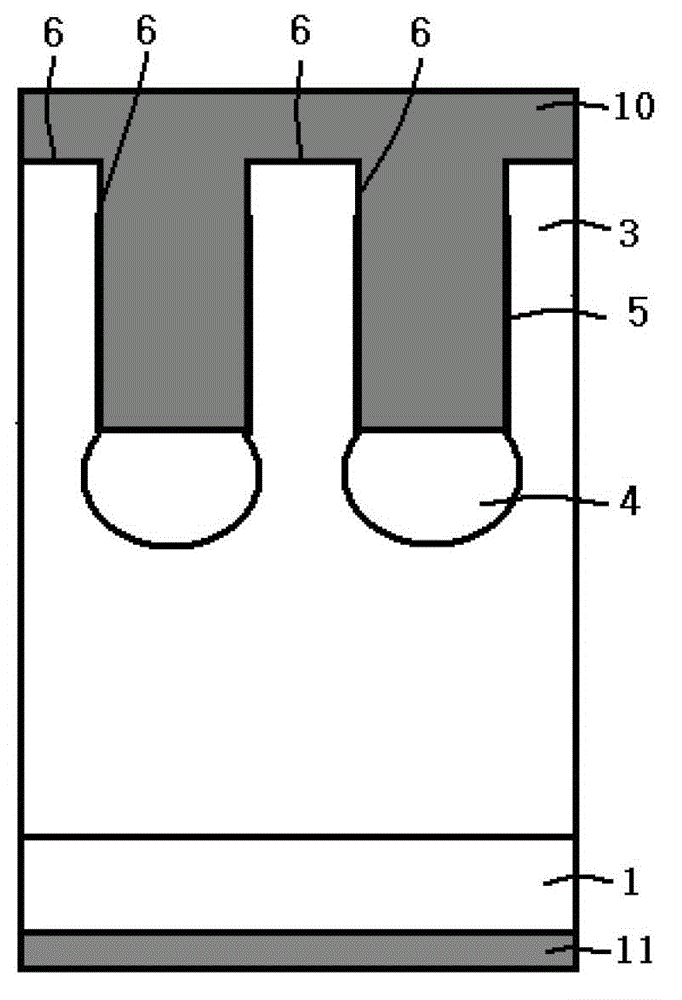

[0039] Figure 5 It is a sectional view of a trench semiconductor device of the present invention, combined below Figure 5 The semiconductor device of the present invention will be described in detail.

[0040] A trench semiconductor device, comprising: a substrate layer 1, which is an N conductivity type semiconductor silicon material, and the doping concentration of phosphorus atoms is 1E19 / CM 3 , on the lower surface of the substrate layer 1, the electrodes are drawn out through the lower surface metal layer 11; the first conductive semiconductor material 3, located on the substrate layer 1, is a semiconductor silicon material of N conductivity type, and the doping concentration of phosphorus atoms is 1E16 / CM 3 ; The second conductive semiconductor material 4, located in the inner wall region of the trench, is a semiconductor silicon material of P conductivity type, and the doping concentration of boron atoms is 1E16 / CM 3 , the groove pitch is 1um; the ohmic contact regi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com