Remote intelligent monitoring system for noise in factory environment

An intelligent monitoring system and environmental noise technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of reduced production efficiency, single function, and expanded problems, so as to improve security, adapt to a wide range, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

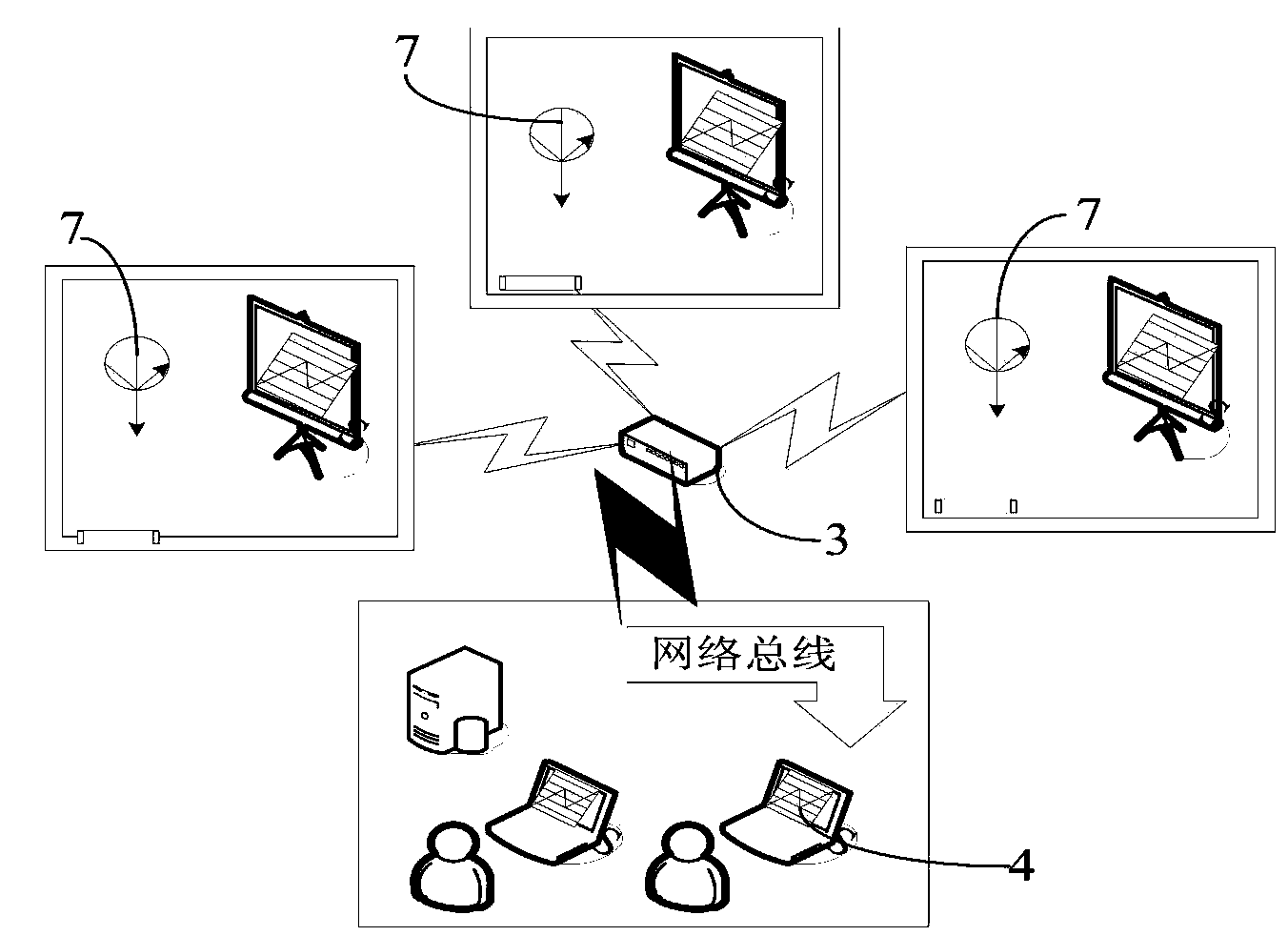

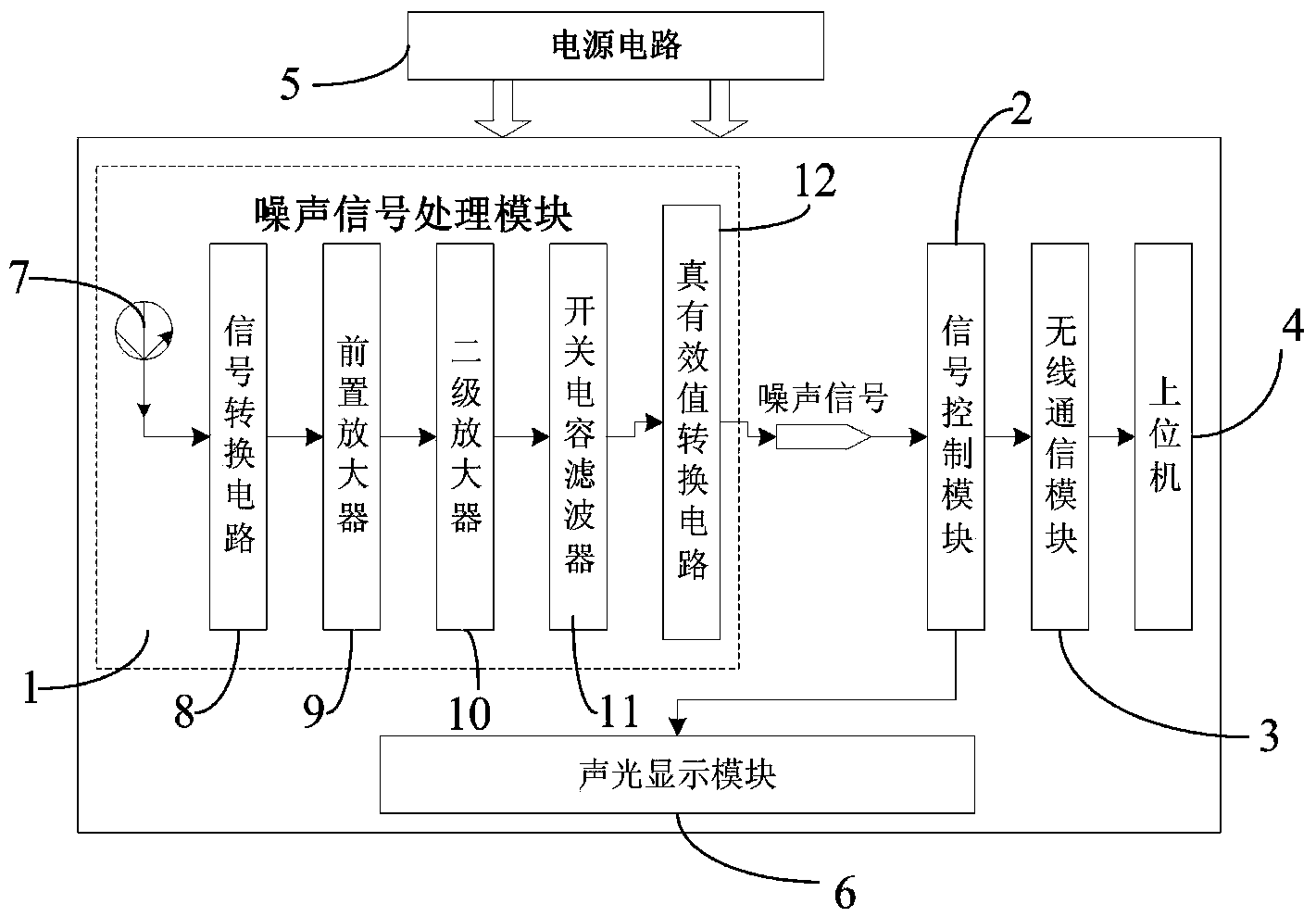

[0021] Such as figure 1 and figure 2 Shown: In order to be able to judge the remote real-time monitoring system of working status and intelligent fault diagnosis according to the noise, unmanned monitoring of factory machines can be realized, and the security strength of the factory can be improved. The present invention includes noise signal processing for obtaining noise signals in the workshop Module 1, the noise processing module 1 is connected to the signal control module 2, and the signal control module 2 is connected to the acousto-optic display module 6; the signal control module 2 judges the working state of the workshop equipment according to the noise signal transmitted by the noise signal processing module 1, and When the workshop equipment breaks down, the signal control module 2 will issue an audible and visual alarm through the acousto-optic di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com