High fabrication tolerance planar waveguide tunable optical attenuator

A planar waveguide, dimming and attenuation technology, which is applied in the field of integrated optics, can solve the problems of process error, inability to achieve the modulation depth, and the core layer and cladding parameters of the adjustable optical attenuator cannot be designed, so as to improve the manufacturing tolerance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

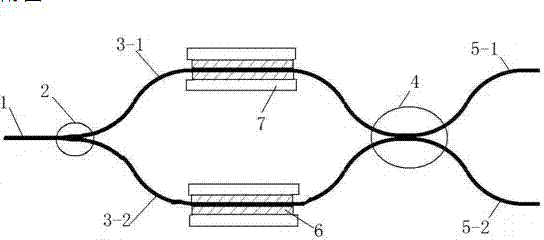

[0016] Embodiment 1: as figure 1 As shown, a planar waveguide tunable optical attenuator with high manufacturing tolerance is given, including a first coupler 2, the first coupler 2 adopts a Y-type coupler, and the input end of the Y-type coupler is connected to the input waveguide 1 connection, the two output ends of the Y-type coupler are respectively connected to the front ends of the upper arm branch 3-1 and the lower arm branch 3-2, and the two input ends of the second coupler 4, that is, the X-type coupler are connected to the upper arm branch 3-1 respectively. The branch 3-1 is connected to the rear end of the lower arm branch 3-2, the two output ends of the X-type coupler are respectively connected to the output waveguide 5-1 and the output waveguide 5-2, and the upper arm branch 3-1 is connected to the lower arm branch 3-1. The arm branch 3-2 is provided with a metal thin film heater 6, and the metal thin film heater 6 is located between the isolation grooves 7. The Y...

Embodiment 2

[0019] Embodiment 2: as figure 2 As shown, a planar waveguide tunable optical attenuator with high manufacturing tolerance is given, including the first coupler 2, the first coupler 2 adopts an X-type coupler, and the two input ends of the X-type coupler are respectively It is connected to the input waveguide 1-1 and the input waveguide 1-2, and the two output terminals of the X-type coupler are respectively connected to the front ends of the upper arm branch 3-1 and the lower arm branch 3-2, and the second coupler 4 is X The two input ends of the X-type coupler are respectively connected to the rear ends of the upper arm branch 3-1 and the lower arm branch 3-2, and the two output ends of the X-type coupler are respectively connected to the output waveguide 5-1 and the output waveguide 5- 2 connection, the upper arm branch 3-1 and the lower arm branch 3-2 are provided with a metal film heater 6, and the metal film heater 6 is located between the isolation grooves 7, by adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com