Method for eliminating motor phase current temperature drift in real-time way

A phase current and temperature drift technology, applied in the direction of measuring current/voltage, measuring electrical variables, measuring devices, etc., can solve problems such as unstable operation state, inability to correct in real time, change electrical devices, etc., to ensure reliable operation and stability. properties, the effect of eliminating zero bias current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

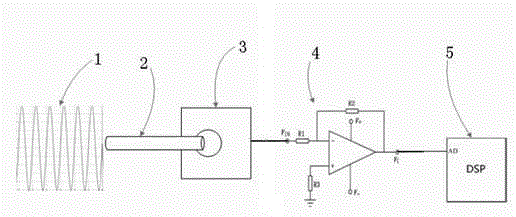

[0013] The method for eliminating the temperature drift of the motor phase current in real time of the present invention comprises the following steps:

[0014] Step 1. Use the current sensor to collect the phase current of the motor. The signal of the current sensor is input to the proportional amplification module for signal amplification. The output signal of the proportional amplification module is transmitted to the analog signal input terminal of the digital signal processing module. The digital signal processing module collects the current sensor The phase current signal of the motor is processed by analog-to-digital conversion;

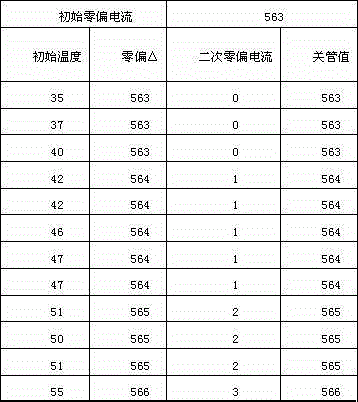

[0015] Step 2. When the phase current sampling system is initially powered on, the sampling value of the current sensor is input to the digital signal processing module through the proportional amplification module, and the digital signal processing module performs digital conversion on the input analog signal, and the converted value is the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com