Water level signal device for high-position pool

A signal device and pool technology, applied in the direction of buoy liquid level indicator, etc., can solve the problems of water and electricity waste, unable to know the telemetry signal device in time, high water consumption, pool water level, no water in the pool and overflow of the pool.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

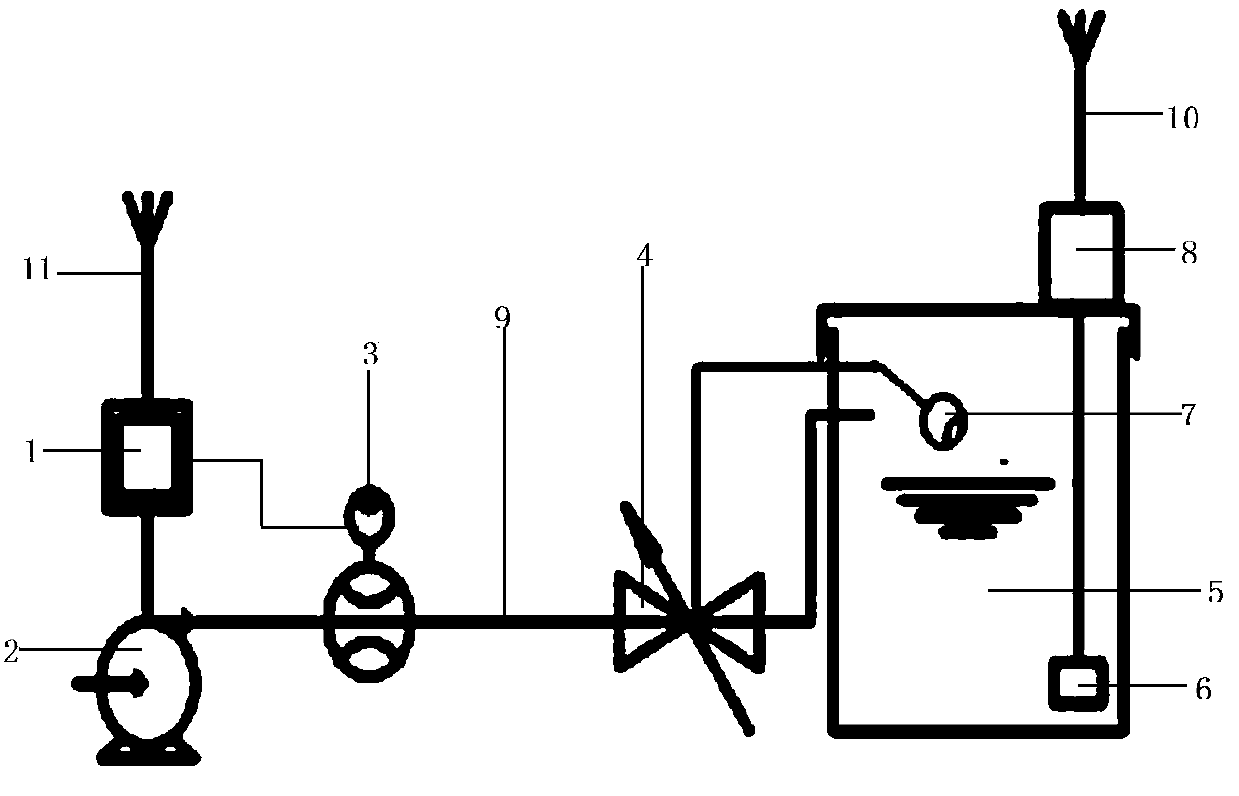

[0020] Embodiment 1: A water level signal device for a high-level pool, comprising a suction pipe 9, a high-level pool 5 and a water pump 2, one end of the water-drawing tube 9 is a water outlet, and the other end is a water inlet, and the water outlet of the suction pipe 9 is connected to the high-level pool 5 , the water inlet of the suction pipe 9 communicates with the water outlet of the water pump 2, and the electromagnetic flowmeter 3 and the ball float valve 4 are installed on the water pipe 9; the installation position of the electromagnetic flowmeter 3 is close to the water inlet of the water pipe 9, the ball float valve 4 The installation position is close to the water outlet of suction pipe 9.

[0021] The floating ball 7 of the floating ball valve 4 described in this embodiment is located in the high-level pool 5; the floating ball valve 4 is located at one end of the high-level pool 5 (that is, the suction pipe 9 where the float valve 4 is installed is close to the...

Embodiment 2

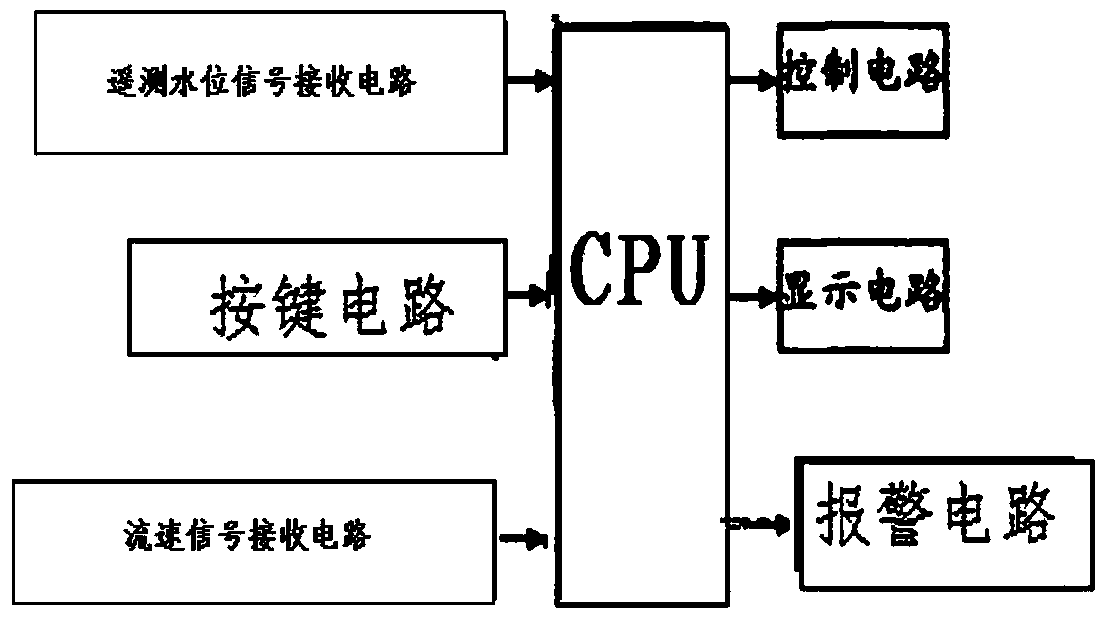

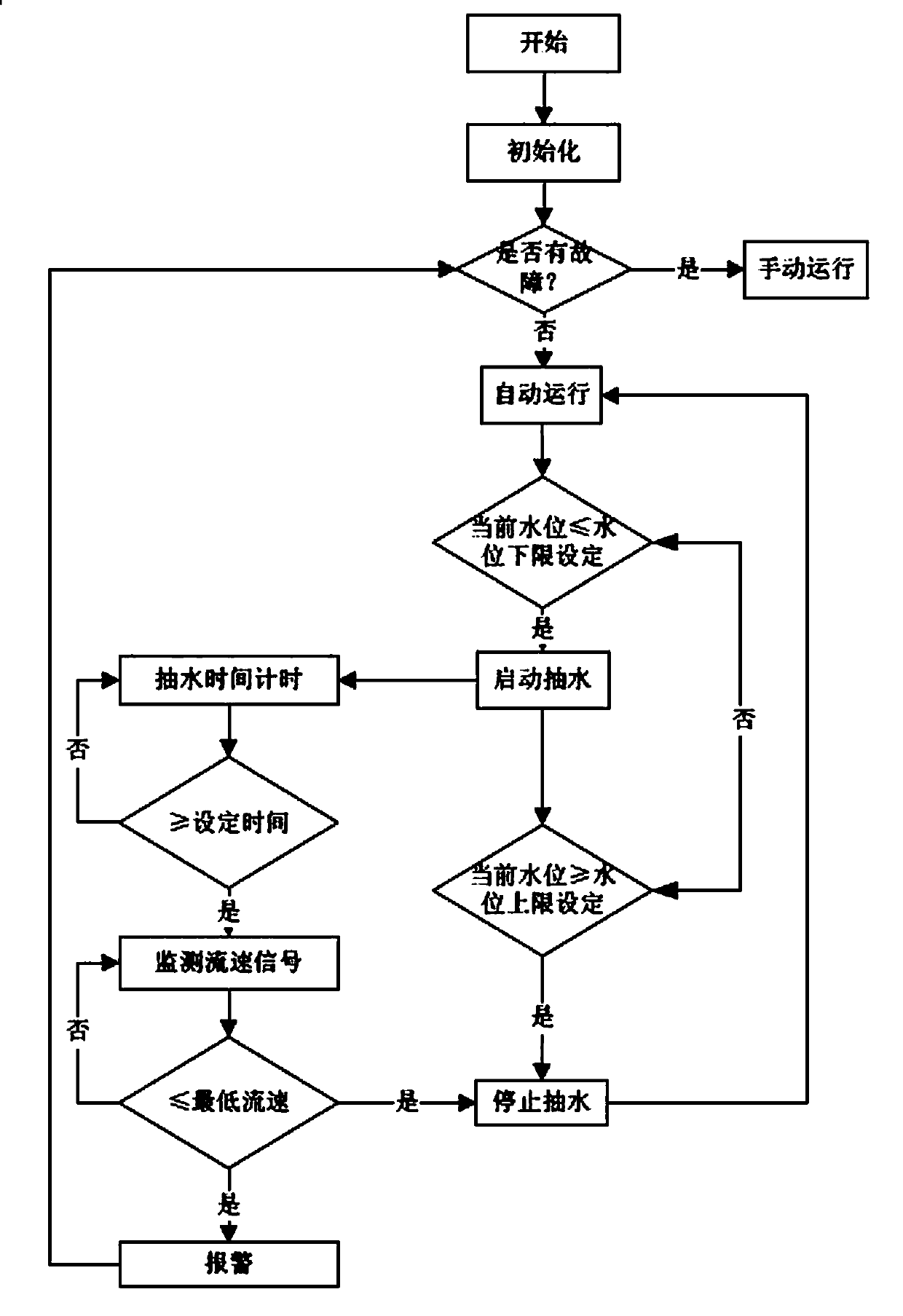

[0024] Embodiment 2: The basic structure of this embodiment is the same as that of Embodiment 1, the difference is that: the device includes a pumping control device 1, and the pumping control device 1 receives the flow velocity signal of the water in the pumping pipe 9 from the electromagnetic flowmeter 3 [ The flow data line of the electromagnetic flowmeter 3 is connected to the pumping control device 1 (specifically connected to the data receiving and processing device of the pumping control device 1)].

Embodiment 3

[0025] Embodiment 3: The basic structure of this embodiment is the same as that of Embodiment 2. The difference is that the device includes a water level telemetry device 8, a signal transmission device 10, and a signal receiving device 11. The signal receiving device 11 is connected to the pumping control device 1, and the water level telemetry Device 8 is connected with signal transmission device 10, and signal transmission device 10 is wirelessly connected with signal receiving device 11, and water level telemetering device 8 passes the water level signal in the high level pool that the water level gauge 6 of water level telemetry device measures through signal transmission device 10, signal receiving The device 11 transmits to the pumping control device 1 .

[0026] The above pumping control device 1 is mainly a PLC control system.

[0027] The above-mentioned water level telemetry device 8 is located at the location of the high level pool 5 , and the water level gauge 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com