Hydraulic antiskid self-locking differential mechanism

A differential and hydraulic technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of increased fuel consumption, affecting differential performance, heavy steering, etc., and achieves easy manufacturing and improved The effect of passability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

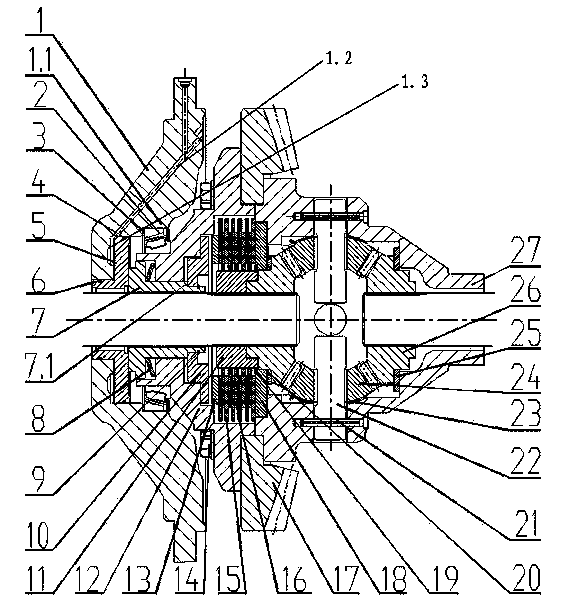

[0020] The core of the present invention is to provide a hydraulic anti-skid self-locking differential. When the hydraulic anti-skid self-locking function makes the driving ability of one wheel fail, the other wheel can still provide driving force to improve the trafficability of the vehicle. The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, the driven spiral bevel gear 17 is connected with the differential left case 12 and the differential right case 27 by bolts 14 . Four pin shafts 22 are embedded in the circular holes of the differential gear right housing 27, and are fixed by cylindrical pins 21. Spherical spacer 23, bevel gear 24 are enclosed within on pin shaft 22 successively, and spherical spacer 23 outer diameters have projections, are placed in the groove of differential gear right shell 27 during installation, prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com