Sliding vane type working medium pump of two-phase flow refrigerating system

A refrigeration system, sliding vane technology, used in rotary piston pumps, pumps, rotary piston machines, etc., to improve motor efficiency, reduce system load, and save system energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

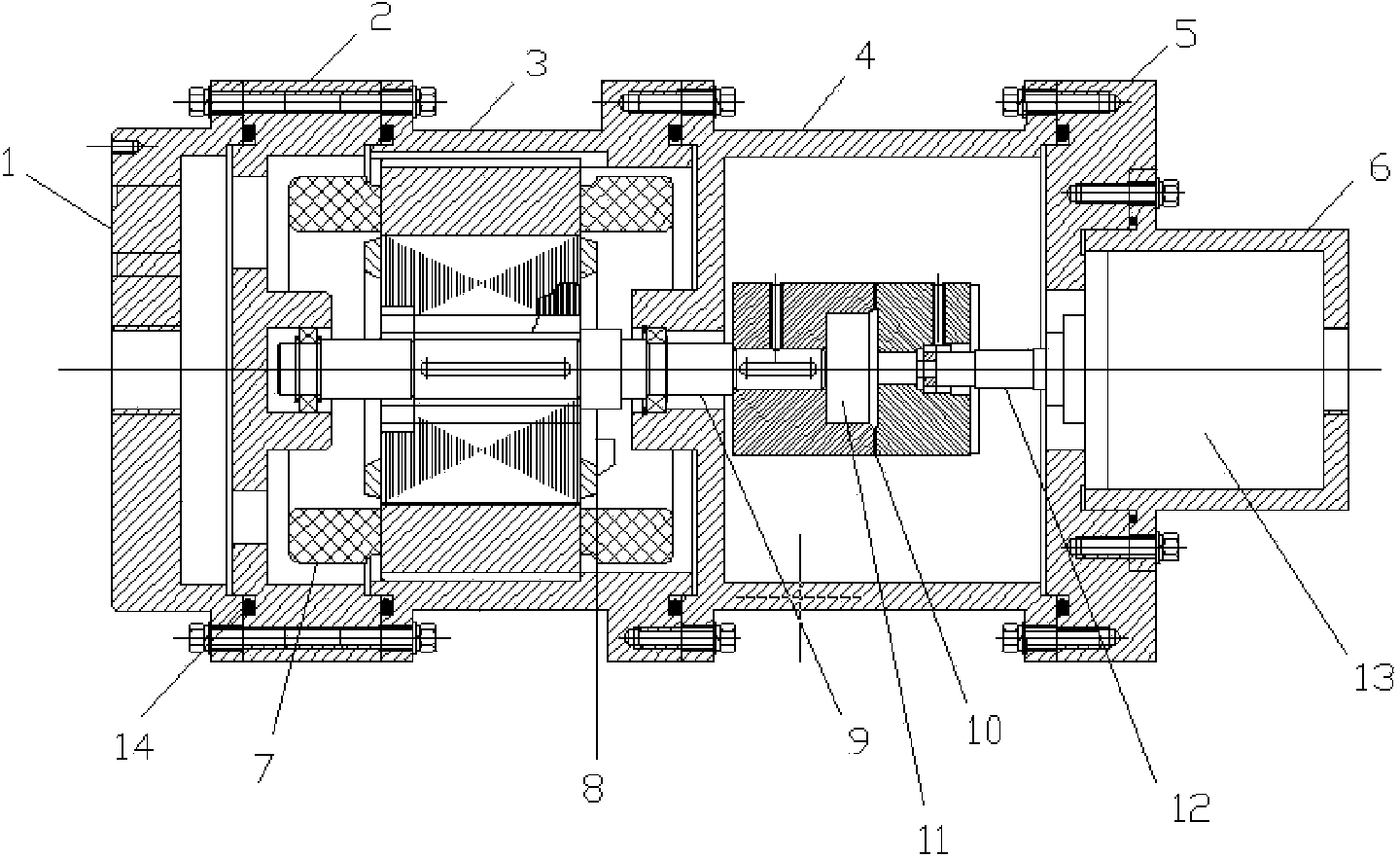

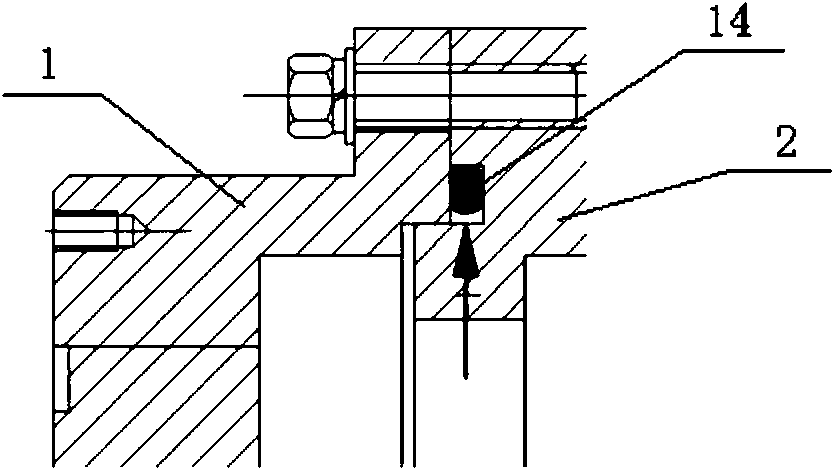

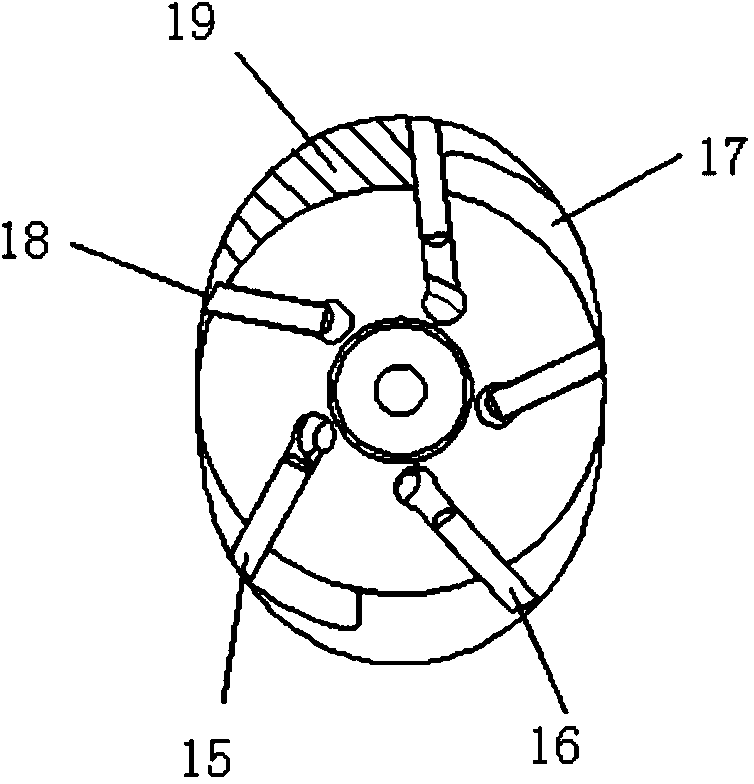

[0041] see figure 1 and Figure 9, the present invention includes an air intake cover 1, a bearing seat 2, a motor housing 3, a coupling body 4, a rotor housing front gland 5 and a rotor housing 6 connected in series, an air intake cover 1, a bearing seat 2, a motor The shell 3, the coupling body 4, the rotor shell front gland 5 and the rotor shell 6 are all positioned by seams and connected together by flanges, and the seams are provided with fluorine-resistant O-type seals for sealing. Ring 14, a sealing groove is arranged on the outer side of the seam, and a fluorine-resistant O-ring 14 is installed in the sealing groove. The air intake cover 1, bearing seat 2, motor housing 3, coupling body 4, rotor housing front gland 5 and rotor housing 6 are connected in series in sequence by a fluorine-resistant O-ring 14 through the groove sealing structure, and M8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com