Hydraulic return travel radial plunger pump adopting double-column slide valves for oil distribution

A radial column and plunger technology, which is applied to the components of the pumping device for elastic fluids, pumps, multi-cylinder pumps, etc., can solve the problems of high processing difficulty of the distribution shaft, unreliable return speed, and difficult to achieve sealing. , to achieve the effect of compact structure, low noise and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

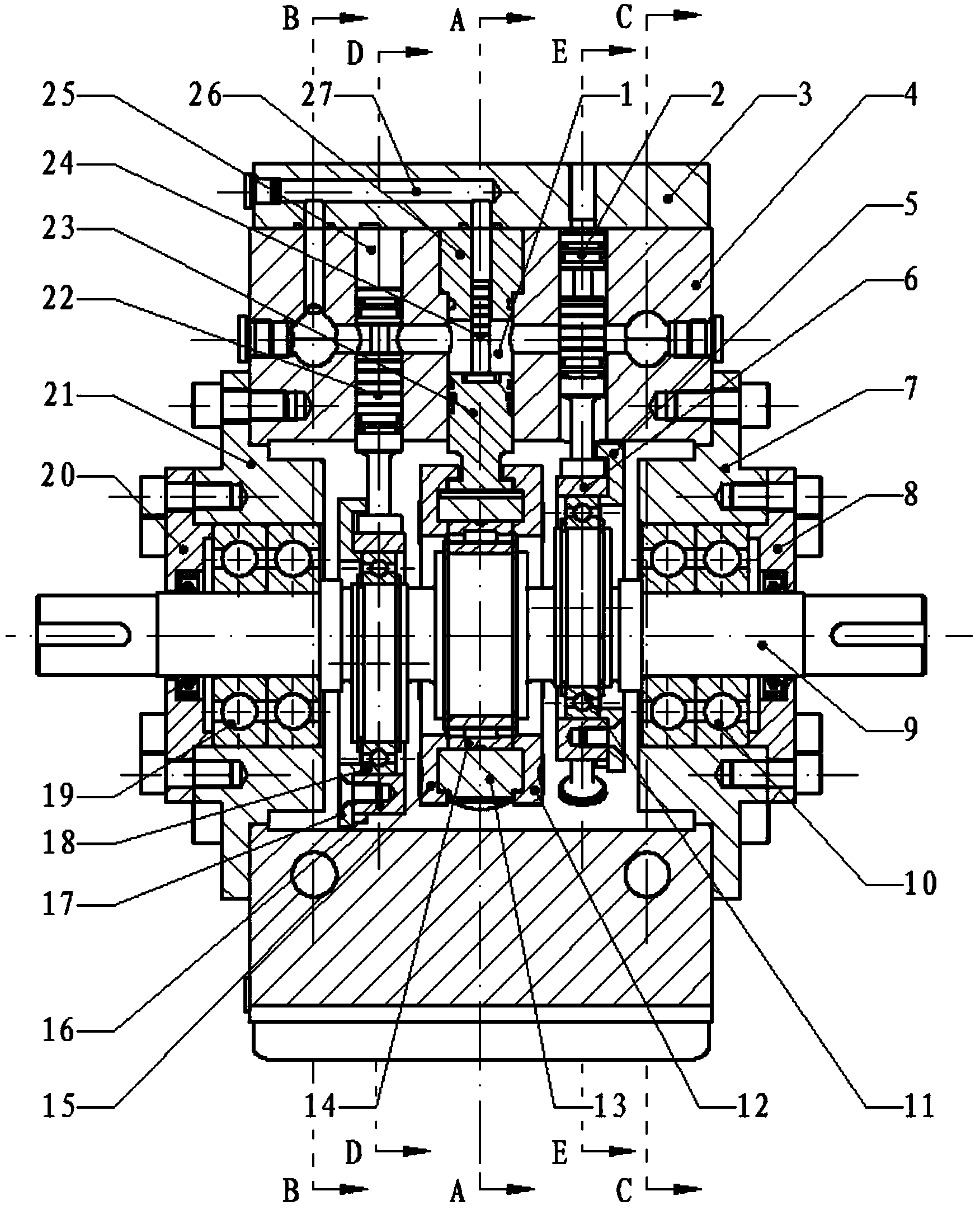

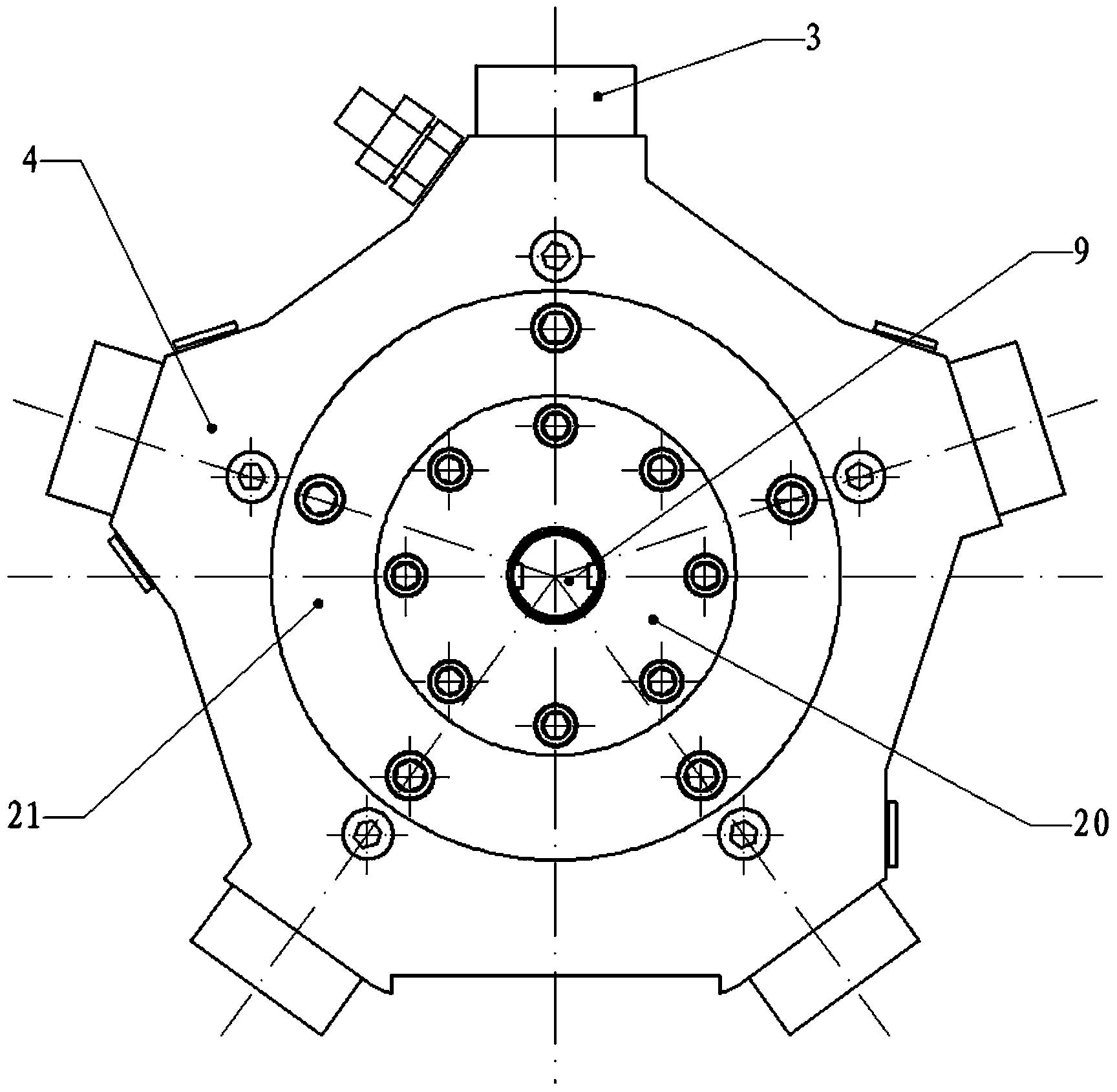

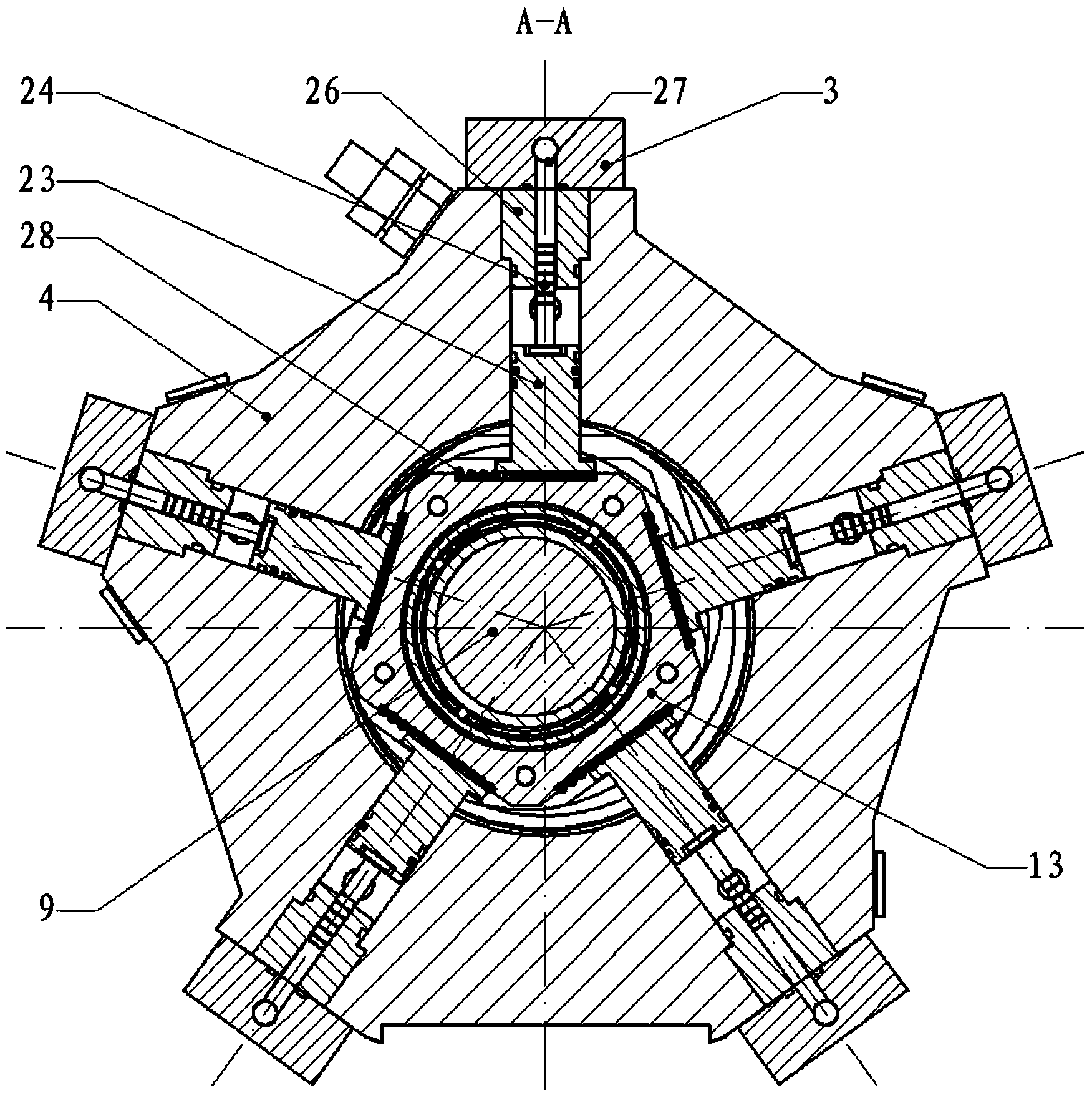

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] refer to figure 1 , figure 2 and image 3 , a hydraulic return radial piston pump adopting double-row sliding valve oil distribution, including a pump body 4, five plunger groups 37 are installed on the pump body 4, and the five plunger groups 37 are evenly distributed in the radial direction On the same plane, each plunger group 37 includes a plunger 23, a plunger return guide post 24, a plunger return guide sleeve 26, and a plunger gland 3. One end of the plunger return guide post 24 abuts against the plunger 23, and the other One end is inserted into the plunger return guide sleeve 26, and moves axially with the plunger 23, the plunger 23 and the plunger return guide sleeve 26 are inserted into the plunger hole 1 on the pump body 4, and the plunger gland 3 passes through The screw is installed on the pump body 4, and the plunger return guide sleeve 26 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com