Thermodynamic cycle method for prime mover on basis of correct timing constant volume combustion mode

A technology of constant volume combustion and thermodynamic cycle, which is applied in the field of prime movers, can solve the problems that the heating process cannot realize constant pressure and then constant volume heating, it is difficult to adapt to changes in working conditions, and the conversion efficiency of thermal power is not high, so as to achieve low requirements and reduce impact Noise, the effect of uniform low-temperature combustion

Active Publication Date: 2014-07-23

GREEN ENERGY HIGH TECH GRP +5

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The third is the Stirling cycle. The cycle process includes isothermal compression process, isothermal combustion process, isothermal expansion process, and isothermal exothermic process. The working medium absorbs heat from a high-temperature heat source during the isothermal expansion process. Heat release to a low temperature heat source, inefficient due to its combustion temperature and regenerator limitations

Although the existing relevant patents have elaborated on interstage cooling of multi-stage compression and energy recovery of exhaust gas, the heating process cannot realize the real constant pressure and then constant volume heating, so the thermal power conversion efficiency is not high, and it is also difficult to adapt to industrial conditions. Situation changes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

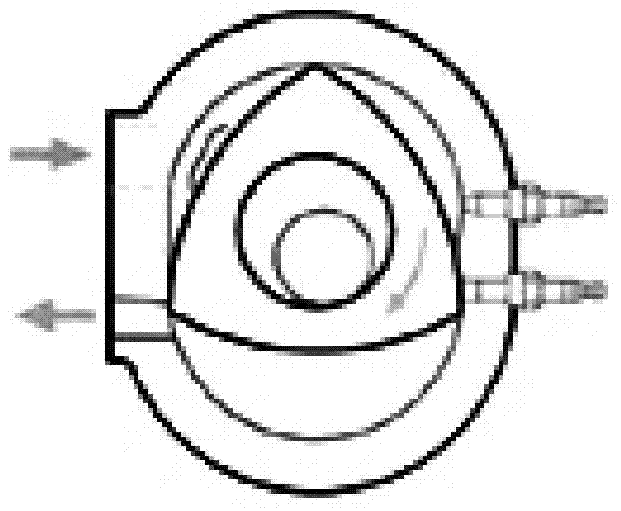

[0164] Other embodiments: The novel thermodynamic cycle of a prime mover may include multi-stage compression, multi-stage inter-stage cooling and multi-stage expansion, and the cycle system and method are the same as those in the embodiment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

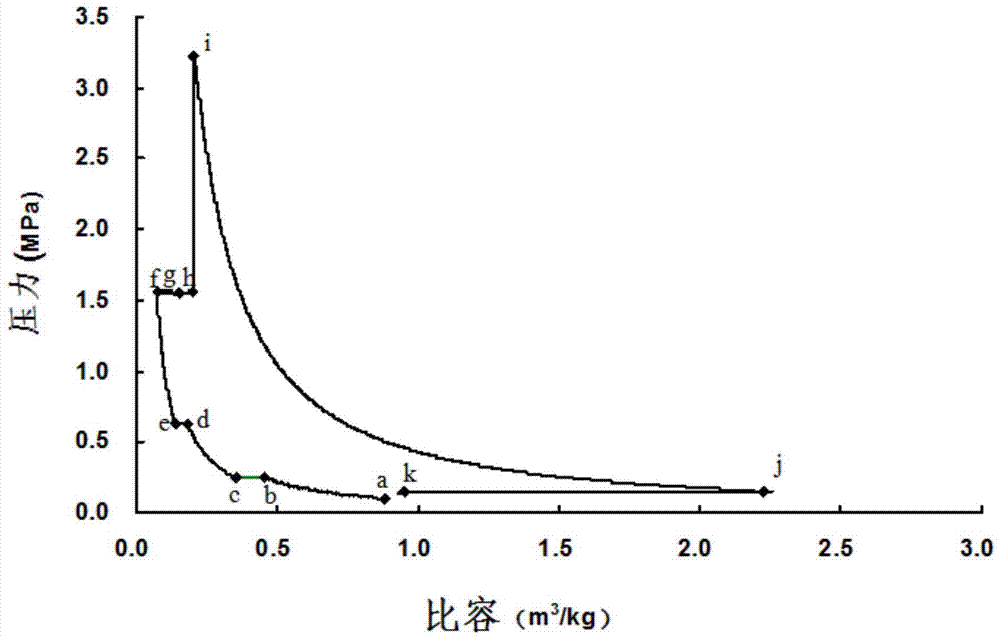

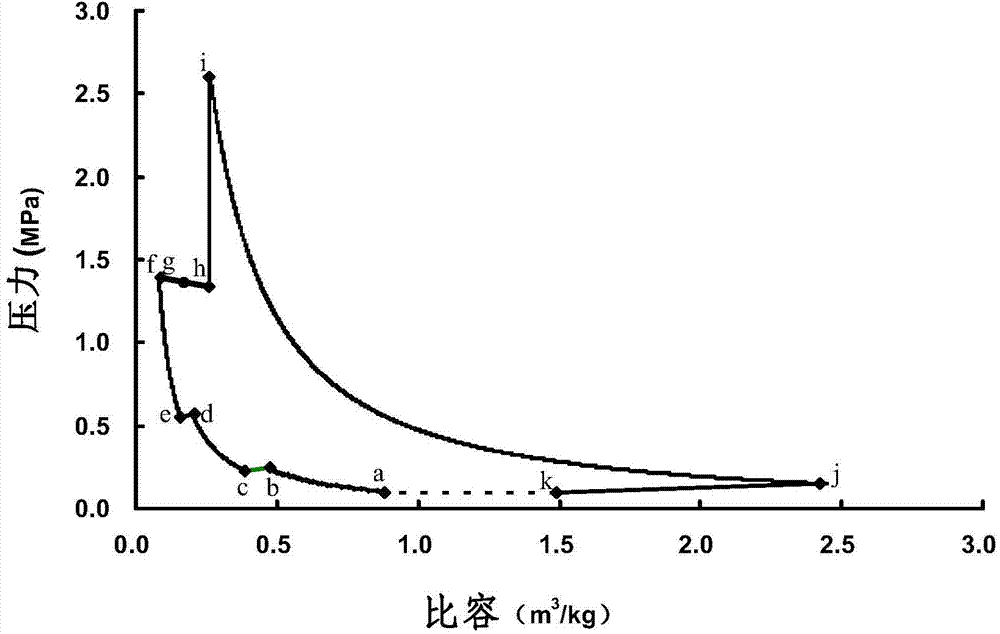

The invention provides a thermodynamic cycle method for a prime mover on the basis of a correct timing constant volume combustion mode. In thermodynamic cycle, a multistage compression interstage cooling process, a countercurrent flow heat exchange process, a correct timing constant volume combustion process and an adiabatic expansion process are included, and thermal energy is converted into mechanical energy in the thermodynamic cycle. Compression power consumption is reduced through the multistage compression interstage cooling process; through the countercurrent flow heat exchange process, enthalpy of working media to be exhausted to the external environment originally is recycled and used for the thermodynamic cycle, and the utilization rate of the thermal energy is improved; through the correct timing constant volume combustion process, long-time uniform low-temperature constant volume combustion is achieved, generation of harmful pollutants such as HC, CO, PM and NOx is effectively suppressed, and meanwhile combustion efficiency is improved; through the adiabatic expansion process, pressure after expansion is approximate to ambient pressure, and work is fully done in an expanding mode. The method provides orientation for design of efficient low pollutant emission and high-performance prime movers in future.

Description

technical field [0001] The invention relates to a prime mover, in particular to a thermodynamic cycle method based on a prime mover in a timing and constant volume combustion mode. Background technique [0002] Improving the efficiency of the prime mover and reducing emissions have an important positive effect on saving resources and protecting the environment. Through the improved cycle process and combustion organization, the efficiency of the prime mover can be improved and the emission of harmful pollutants can be reduced. [0003] The cycle of a typical internal combustion engine generally includes three types of thermodynamic cycles: the first type, the constant volume combustion cycle is also called the Otto cycle, and its heat release process is similar to the constant volume combustion process. Gasoline engines generally use this cycle method, and the cycle process includes isentropic Compression process, isovolumic combustion process, isentropic expansion process ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F02G1/00

CPCF01C1/356F02B53/08F02B2053/005Y02T10/12

Inventor 张孔明梁世希金则兵王科张帆朱建明谢昕周松景周群王彦超姜进刘敬平廖诚杨汉乾

Owner GREEN ENERGY HIGH TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com