Method for measuring injection allocation well casing external flow through ultrasonic Doppler-correlation method

A technology of ultrasonic and related methods, used in surveying, earth-moving, wellbore/well components, etc., can solve the problems of low cost and radioactive injury cost of construction personnel, and achieve the effect of no radioactive pollution and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

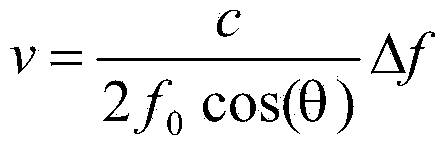

[0018] An ultrasonic Doppler-correlation method for measuring the flow rate outside the injection well pipe, using such as figure 1 As shown in the device, the device is placed inside the oil jacket 2, and the main body of the device is provided with a reflective liquid tank 3, which contains the reflective liquid, and when it is sprayed out through the nozzle, it forms droplets, which are called acoustic wave reflective droplets 6 . An upstream ultrasonic probe 4 and a downstream ultrasonic probe 5 are fixed on the main body, and the ultrasonic probes have an integrated structure of transmitting and receiving, each of which can transmit and receive independently.

[0019] The method includes the following steps:

[0020] (1), select the ultrasonic Doppler-correlation flow logging tool string, the instrument is equipped with a reflective liquid releaser, the reflective li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com