High-temperature six-parameter combination tester, test system and test method

A technology of parameter combination and tester, which is applied in the directions of measurement, earthwork drilling, mining fluid, etc., to achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

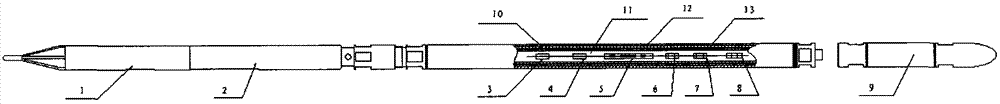

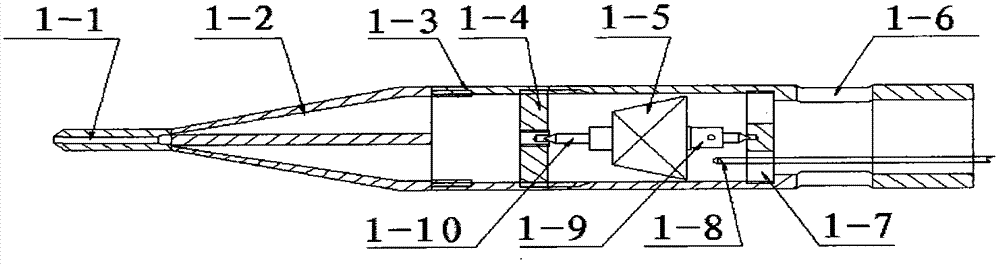

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

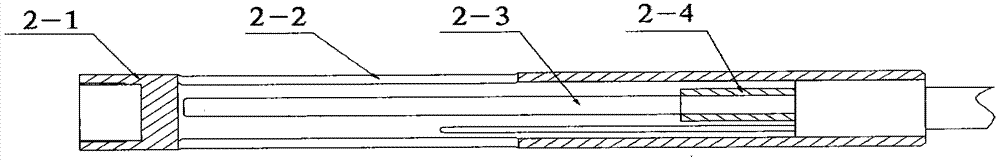

[0031] When assembling the tester, first connect the sensors and output signal lines one by one, and then put multiple sensors into the sensor assembly; each output signal line passes through the sensor signal channel and connects to the fixed frequency transmitter and data collector 5. The other end of the fixed-frequency transmitter and data collector is sequentially connected to the natural gamma ray detector 6, the magnetic positioning 7, and the power supply system 8 to form the core part, which is embedded in the pressure-bearing protective shell 12, and the pressure-bearing protective shell 12 The port of the sensor assembly is connected to the signal channel 11 of the sensor assembly, sealed with a copper ring, the other end of the sensor assembly is connected to the dryness measurement assembly 2, and the other end of the water-containing electrode as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com