High-energy pulse-type magnetron sputtering method and magnetron sputtering device

A magnetron sputtering and pulse sputtering technology, which is applied in sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problem of rough coating surface, poor coating finish, and poor adhesion of thick ion coating and other problems, to achieve the effect of improving uniformity and other characteristics, precise adjustment methods, and eliminating thermal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

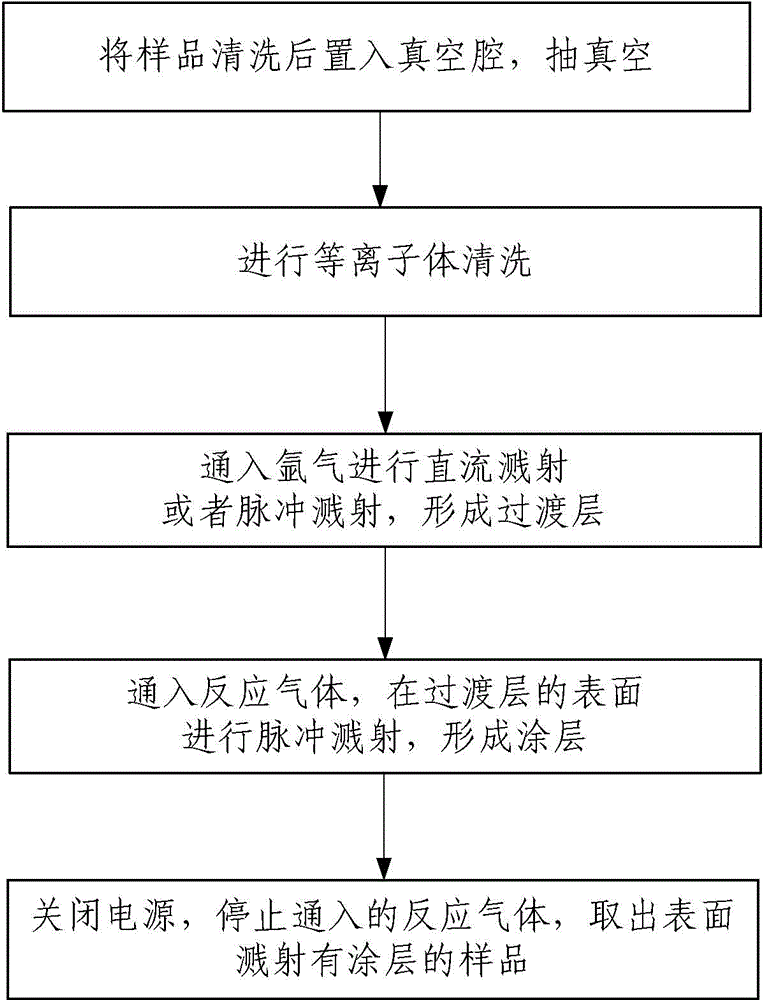

[0042] The following examples illustrate the high-energy pulsed magnetron sputtering method of the present invention by taking the sputtering TiN coating as an example, which specifically includes the following steps:

[0043] Step 1: Install the Ti target on the sputtering cathode; select a metal, plastic or semiconductor substrate as a sample, put it into the vacuum chamber 4 after cleaning, degreasing, and drying, and install it on the workpiece; vacuum the vacuum chamber 4 Vacuum, so that the gas pressure in the vacuum chamber 4 is lower than 1E-4mbar.

[0044] Step 2: Add argon gas Ar, the gas flow rate of the argon gas is 120 sccm, until the entire sputtering process is over; the sample is plasma cleaned, and the bias voltage is applied to the sample for about 10 minutes (value range), and the bias power is set to bias The pulse time of piezoelectric power supply is 0.8μs, the pulse frequency of bias power supply is 240kHz, the voltage of bias power supply is 50V, and th...

Embodiment 2

[0053] The following examples illustrate the high-energy pulsed magnetron sputtering method of the present invention by taking the sputtering CrN coating as an example, which specifically includes the following steps:

[0054] Step 1: Clean, degrease, and dry the sample to be coated and put it into the vacuum chamber 4, and install the cathode target in the vacuum chamber 4, and then perform vacuum pumping to make the gas in the vacuum chamber 4 Pressure below 8E-5 mbar. The cathode target is a Cr target, and the purity of the target is greater than or equal to 99%.

[0055] Step 2: fill in argon gas, set the flow rate of the gas to 120 sccm, perform plasma cleaning on the sample, apply a bias voltage to the sample for 20 minutes, and set the bias voltage power supply to a power pulse time of 0.4 when applying the bias voltage μs, the pulse frequency of the bias power supply is 5kHz, the voltage of the bias power supply is 20V, and the current of the bias power supply is 0.1A...

Embodiment 3

[0060] The following examples illustrate the high-energy pulsed magnetron sputtering method of the present invention by taking the sputtering TiAlCN coating as an example, which specifically includes the following steps:

[0061] Step 1: Clean, degrease, and dry the sample to be coated and put it into the vacuum chamber 4, and install the cathode target in the vacuum chamber 4, wherein the target is a bipolar target, which is divided into Ti target and The Al target is then evacuated to make the gas pressure in the vacuum chamber 4 lower than 1E-4 mbar after evacuation. The purity of the target is greater than or equal to 99%.

[0062] Step 2: fill in argon gas, set the flow rate of the gas to 80 sccm, perform plasma cleaning on the sample, apply a bias voltage to the sample for 10 minutes, and set the bias power supply to a power pulse time of 2.3 μs when applying the bias voltage, The pulse frequency of the bias power is 350kHz, the voltage of the bias power is 50V, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com