A method for extracting gold by microwave roasting of gold-containing sulfur-arsenic concentrate

A technology of microwave roasting and sulfur arsenic concentrate, applied in the field of gold recovery, can solve the problems of insignificant increase in leaching rate, easy sintering, high energy consumption, etc., and achieve the effects of saving pretreatment time, preventing sintering, and improving leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

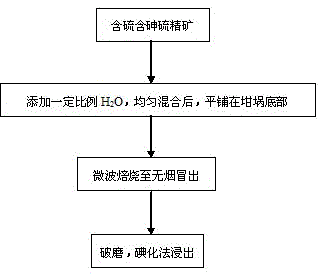

[0039] A new gold-containing sulfur arsenic concentrate microwave roasting gold extraction method, the specific steps are:

[0040] (1) Add a certain proportion of H to the gold-bearing sulfur-arsenic concentrate 2 O, its best mass ratio is: 10:1. gold-bearing sulfur arsenic concentrate and H 2O mix evenly until it becomes a moist block, spread it on the bottom of the crucible, the laying thickness is 1cm-3cm, the best laying thickness is 2cm. The crucible is made of a material that does not absorb microwaves, the best material being quartz.

[0041] (2) Put the crucible in an industrial microwave oven with a certain power and bake until there is no smoke. Stop microwave heating.

[0042] (3) After microwave roasting, the gold-sulfur-arsenic concentrate is ground to -200 mesh, and then leached by iodination method, and the leaching rate of the slag is calculated.

[0043] V embodiment

Embodiment 1

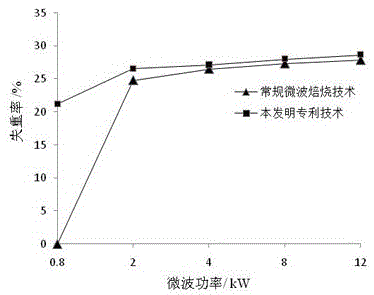

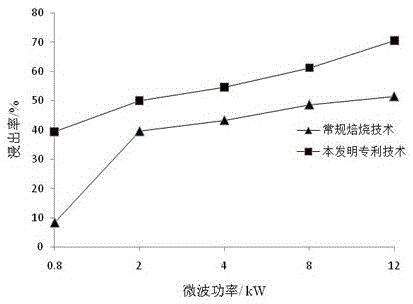

[0044] Example 1, spread 50g of gold-containing sulfur-arsenic concentrate on the bottom of the crucible, the paving thickness is 2cm, put it in an industrial microwave oven, adjust the microwave power to 800W, and there is no obvious reaction after microwave heating for 30min, stop the microwave, take out the crucible, Weigh after cooling, the weight has no obvious change compared with before microwave roasting, see the attached figure 1 . Then grind the gold-containing sulfur-arsenic concentrate after microwave roasting to -200 mesh, and then use the iodide method for leaching, and the gold leaching rate is 8.25%. figure 2 .

[0045] After adding 5g of water to 50g of gold-containing sulfur-arsenic concentrate, spread it on the bottom of the crucible with a thickness of 2cm, place it in an industrial microwave oven, and adjust the microwave power to 800W. After 30 minutes of microwave heating, no smoke comes out, stop the microwave , took out the crucible, weighed after c...

Embodiment 2

[0046] Example 2, spread 100g of gold-containing sulfur-arsenic concentrate on the bottom of the crucible with a laying thickness of 2cm, place it in an industrial microwave oven, adjust the microwave power to 2kW, and after microwave heating for 60min, no smoke comes out, stop the microwave, Take out the crucible, weigh after cooling, the weight loss rate is 24.80%, see the attached figure 1 . Then grind the gold-containing sulfur and arsenic concentrate after microwave roasting to -200 mesh, and then use the iodide method for leaching, and the gold leaching rate is 39.51%. figure 2 .

[0047] After adding 10g of water to 100g of gold-containing sulfur and arsenic concentrate, spread it on the bottom of the crucible with a thickness of 2cm, place it in an industrial microwave oven, adjust the microwave power to 2kW, and after microwave heating for 60min, no smoke comes out, stop the microwave , took out the crucible, weighed after cooling, the weight loss rate was 26.57%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com