Cleaning agent for chip capacitors

A chip capacitor and cleaning agent technology, which is applied in detergent compositions, soap detergent compositions, surface active non-soap compounds and cleaning compositions, etc. Improves cleaning power, helps peel off, and reduces interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

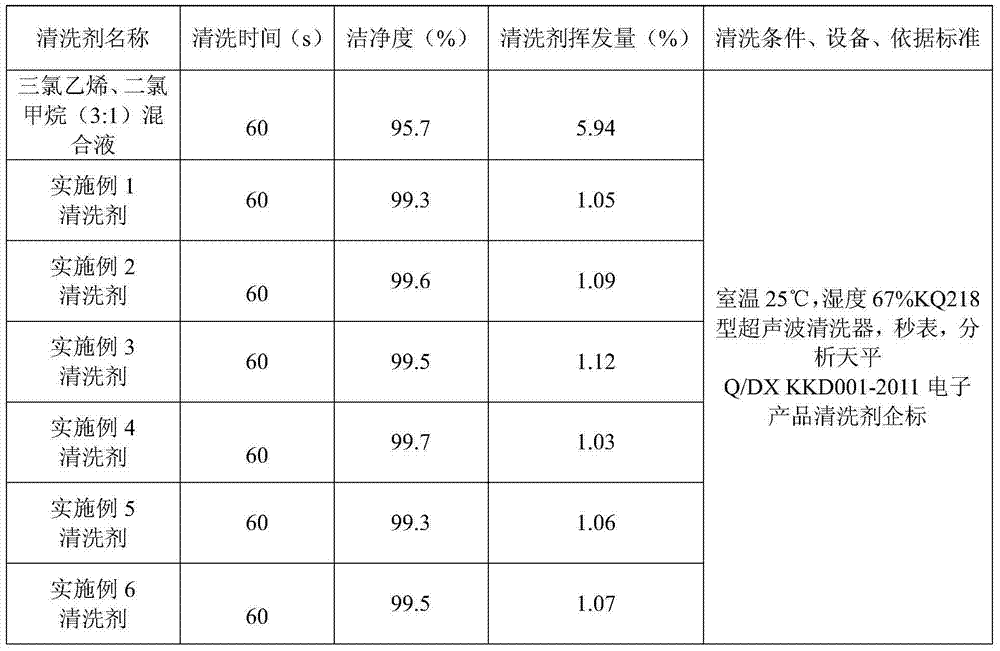

Examples

preparation example Construction

[0015] A preparation method for a cleaning agent for patch capacitors, comprising the following steps:

[0016] 1. Put ethanol and surfactant in a stirred reactor, and stir at a speed of 100-150r / min at room temperature until completely dissolved;

[0017] 2. Add ethyl glutarate, diethylene glycol butyl ether, and ethanol isobutyl ester to the mixed solution obtained in step 1, and stir at a speed of 50-60r / min until uniformly mixed;

[0018] 3. Slowly drop triethanolamine into the mixed solution obtained in step 2, and stir at a speed of 50-60 r / min, which is the cleaning agent of the present invention.

Embodiment 1

[0020] A cleaning agent for patch capacitors, consisting of the following components by weight percentage: 45% ethanol, 25% diethyl glutarate, 12% diethylene glycol butyl ether, 8% isobutyl acetate, ten Sodium dialkylbenzene sulfonate 6%, triethanolamine 4%.

[0021] A preparation method for a cleaning agent for patch capacitors, comprising the following steps:

[0022] 1. Put ethanol and surfactant in a stirred reactor, and stir at a speed of 120r / min at room temperature until they are completely dissolved;

[0023] 2. Add ethyl glutarate, diethylene glycol butyl ether, and ethanol isobutyl ester to the mixed solution obtained in step 1, and stir at a speed of 55 r / min until uniformly mixed;

[0024] 3. Slowly drop triethanolamine into the mixed solution obtained in step 2, and stir at a speed of 55 r / min, which is the cleaning agent of the present invention.

Embodiment 2

[0026] A cleaning agent for patch capacitors, consisting of the following components by weight percentage: 55% ethanol, 20% diethyl glutarate, 10% diethylene glycol butyl ether, 5% isobutyl acetate, ten Sodium dialkylbenzene sulfonate 5%, triethanolamine 5%.

[0027] A preparation method for a cleaning agent for patch capacitors, comprising the following steps:

[0028] 1. Put ethanol and surfactant in a stirred reactor, stir at a speed of 100r / min at room temperature until completely dissolved;

[0029] 2. Add ethyl glutarate, diethylene glycol butyl ether, and ethanol isobutyl ester to the mixed solution obtained in step 1, and stir at a speed of 50 r / min until uniformly mixed;

[0030] 3. Slowly drop triethanolamine into the mixed solution obtained in step 2, and stir at a speed of 50 r / min, which is the cleaning agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com