Reflective thermal insulation paint, preparation and applications thereof

A technology of reflective thermal insulation coatings and raw materials, applied in reflective/signal coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of low thermal insulation effect and limited thermal resistance, and achieve lower temperature and better air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation of embodiment 1 tert-acrylic emulsion

[0052] method one

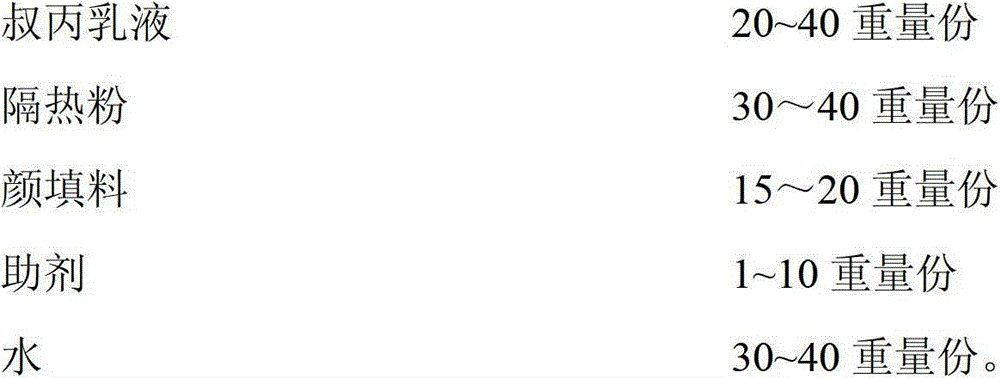

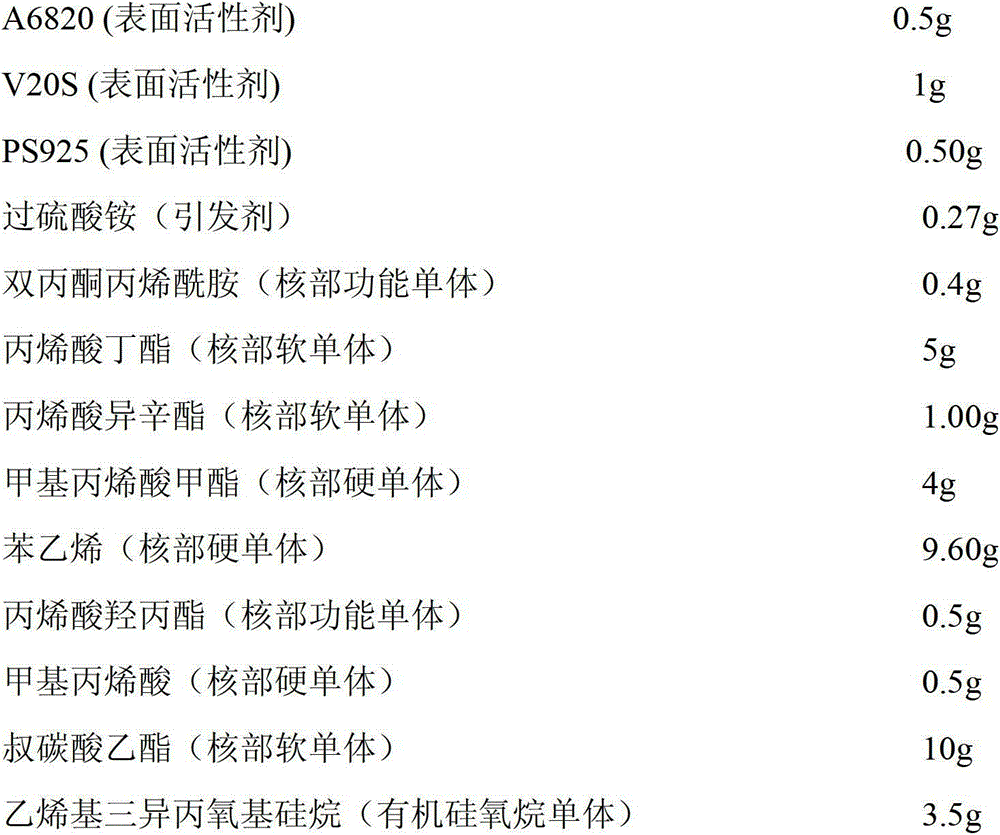

[0053] 1) The raw material composition of the nuclear department

[0054]

[0055]

[0056] 2) Composition of shell raw materials

[0057]

[0058] 3 / 4 of the deionized water in the core raw material components of the above reactant formula, 2 / 5 of the surfactant, 1 / 3 of the initiator, 1 / 4 of the soft monomer of the core, 1 / 6 of the hard monomer of the core, Add 1 / 4 of the core functional monomer and 1 / 6 of the organosiloxane monomer into the reactor, heat up to 80°C under stirring conditions, and react after 15 minutes of stable reaction to form a seed nanocrystal emulsion, and then add the core raw materials dropwise In the core pre-emulsion composed of the remaining part, the weight ratio of the core material to the shell material is 1:0.2; react at 83°C for 2-3 hours to form core layer emulsion particles. Then continue to drop the shell pre-emulsion prepared by mixing the shell r...

Embodiment 2

[0071] Embodiment 2 Preparation of reflective heat-insulating coating

[0072] 1. Reagents

[0073] Dispersant S-70S was provided by Shanghai Zhongcheng Chemical Co., Ltd., and dispersant 2320 was provided by Shenzhen Haichuan Co., Ltd. Wetting agent LB407 and wetting agent EFS4070 were provided by Shanghai Zhongcheng Chemical Co., Ltd. The hydrophilic defoamer 315 was provided by Shenzhen Haichuan Co., Ltd., and the hydrophobic defoamer DF538 was provided by Shanghai Zhongcheng Chemical Co., Ltd. Titanium dioxide 996 was provided by Shanghai Yantai Co., Ltd. 4A molecular sieve was provided by Luoyang Jianlong Co., Ltd. Saiboya nano rubber powder is provided by Yuhang Jiacheng Nonmetal Mining Co., Ltd. Leveling agent LEV-202, provided by Shanghai Zhongcheng Chemical Co., Ltd. Fungicide 515 was provided by Shanghai Chaoling Co., Ltd. Antifungal agent A2W, provided by Shanghai Chaoling Co., Ltd. Wetting agent EFS-407 was provided by Shanghai Zhongcheng Chemical Co., Ltd. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com