MBBR pretreatment method and system for high-ammonia nitrogen micro-polluted raw water

A high-ammonia-nitrogen micro-pretreatment technology, applied in the field of drinking water treatment, achieves the effect of less floor space, less head loss and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is further described below in conjunction with embodiment and accompanying drawing.

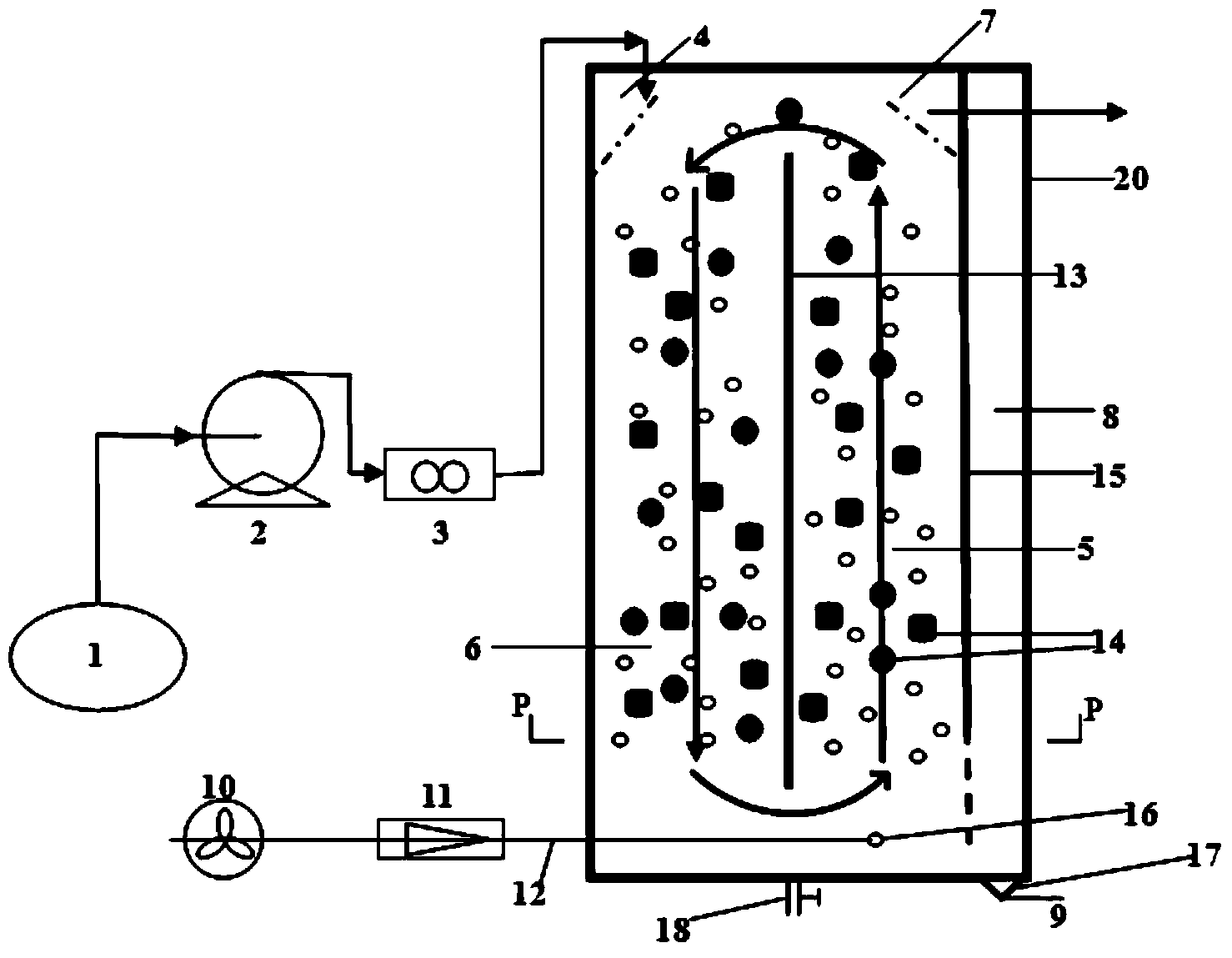

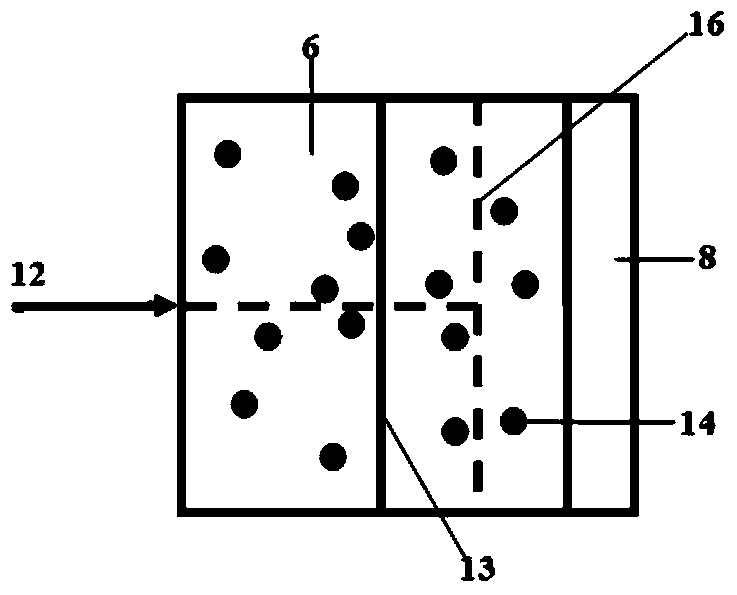

[0058] Figure 1A and Figure 1B Shown is a pretreatment system of a moving bed biofilm reactor with high ammonia nitrogen slightly polluted raw water, the system includes an inlet pump 2, a moving bed biofilm reactor 20 and a blower 10, and the inside of the moving bed biofilm reactor 20 A separation baffle 13 and a diversion wall 15 are provided. The moving bed biofilm reactor is equipped with a separation baffle, so that in the case of aeration in the ascending zone, there are two different flow directions of ascending and reflux. The bottom of the diversion wall 15 is provided with a screen.

[0059] The reaction tank of the moving bed biofilm reactor 20 is a cuboid, and the water inlet channel 4 and the water outlet channel 7 are respectively arranged on both sides of the top of the moving bed type biofilm reactor 20 . The water inlet pump 2 communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com