Method for improving graphitization degree of carbon nano tube

A technology of graphitization degree and carbon nanotubes, which is applied in the direction of chemical instruments and methods, carbon compounds, nanotechnology, etc., can solve the problems of carbon nanotube structure damage, slow heating rate, high energy consumption, etc., and achieve the optimization of carbon tube structure, Increased degree of graphitization and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

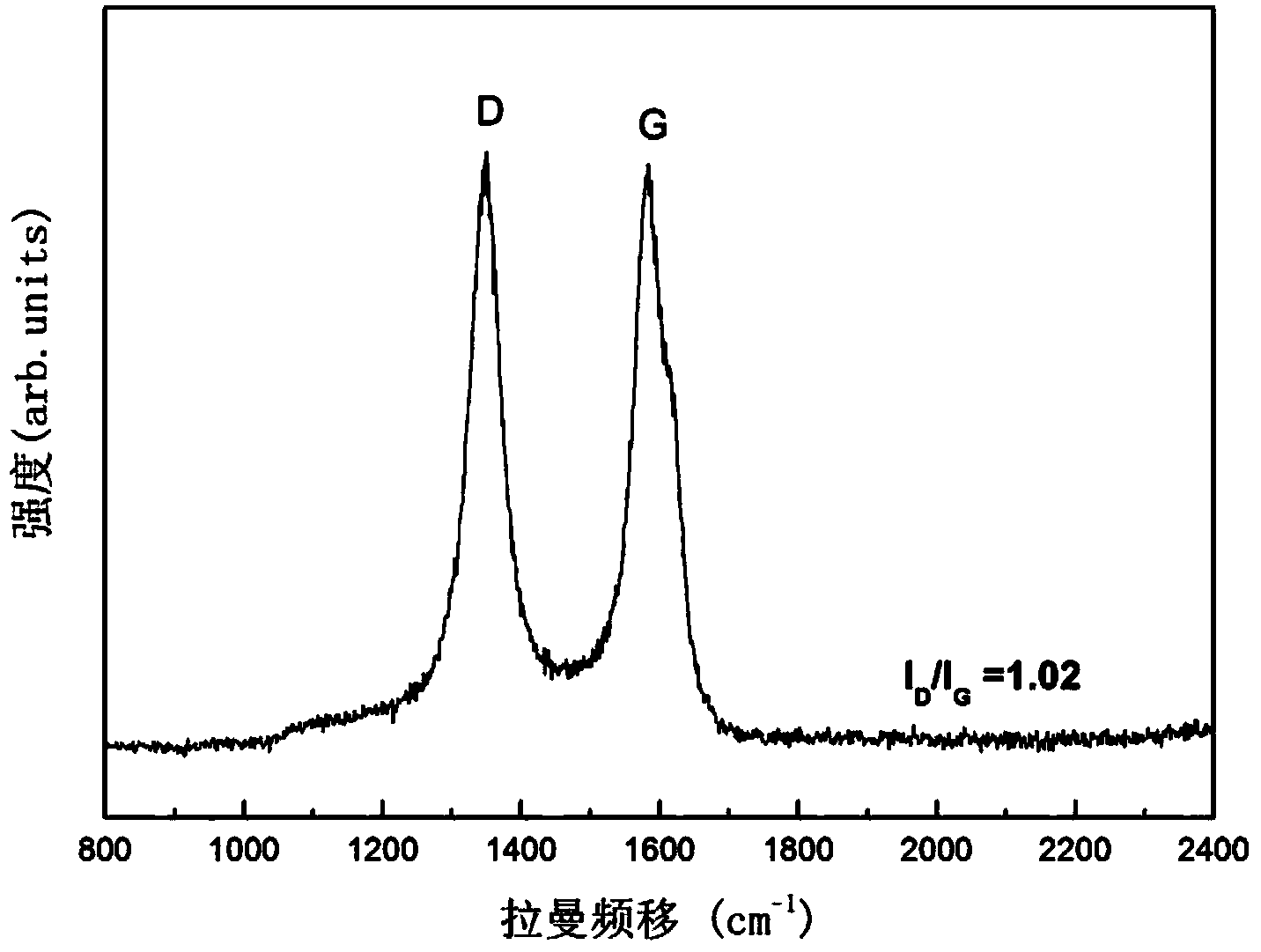

[0022] Such as figure 1 As shown, accurately weigh 2.698g (0.1mol) of nano-sized aluminum powder and 23.954g (0.15mol) of ferric oxide powder according to the molar ratio of 1:1.5, and mix them well to make thermite. Then commercially available CVD carbon nanotubes were placed in a graphite tube with an outer diameter of 6 mm, an inner diameter of 4 mm, and a length of 25 mm and compacted, then both ends of the graphite tube were sealed, and the surface of the graphite tube was coated with thermite. Using metal magnesium strips as the igniter, igniting the thermite, a violent thermite reaction occurs and a large amount of heat is released, which acts on the carbon nanotubes to rearrange the C-C bonds of the carbon tubes and optimize the structure. The processed carbon nanotubes are taken out from the graphite tube, and the degree of graphitization is detected by Raman spectroscopy, and the structural changes are analyzed.

example 2

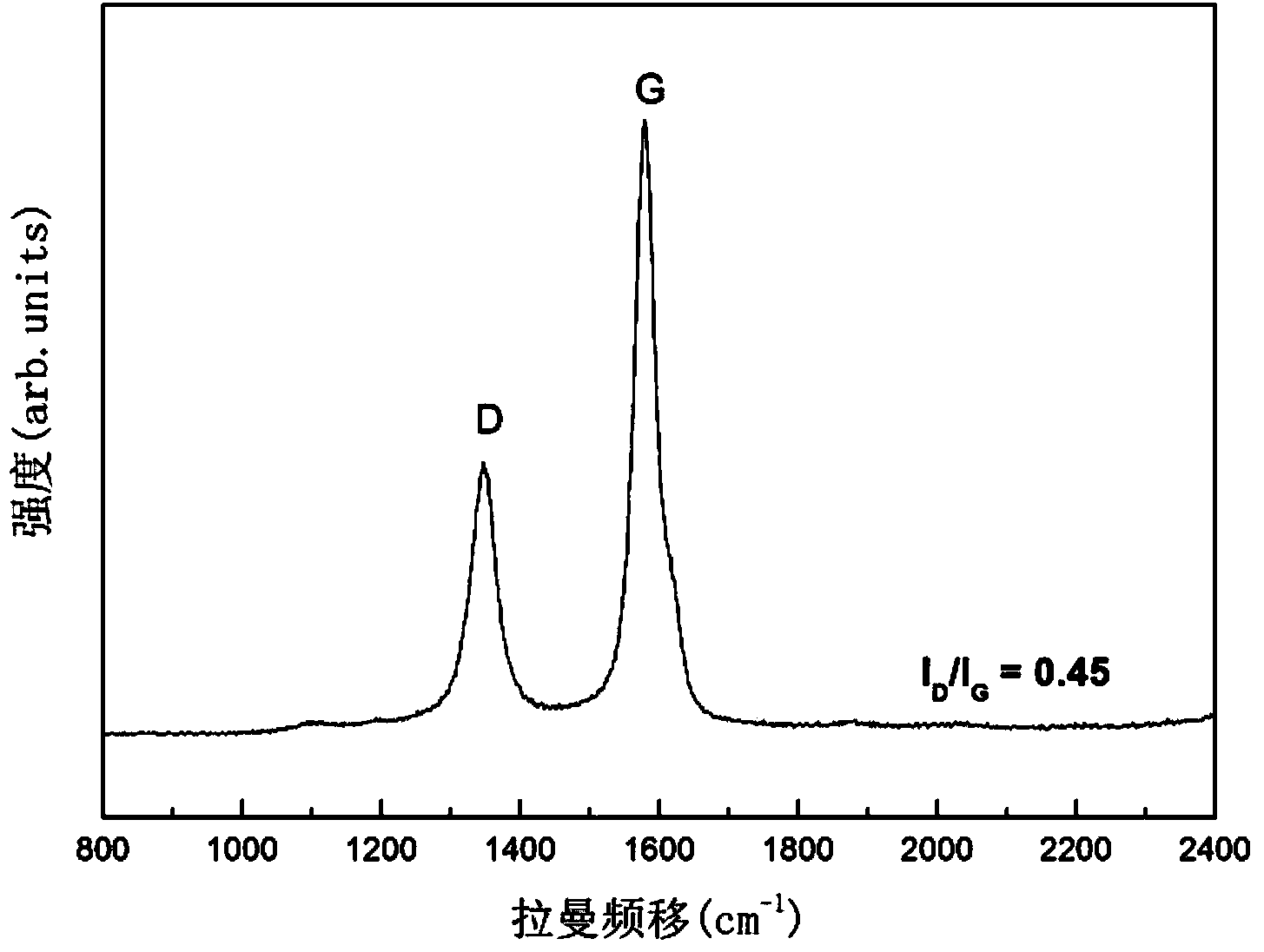

[0024] Such as figure 2 As shown, accurately weigh 2.698g (0.1mol) of nano-scale aluminum powder and 19.163g (0.12mol) of ferric oxide powder according to the molar ratio of 1:1.2, and mix them well to make thermite. Then commercially available CVD carbon nanotubes were placed in a graphite tube with an outer diameter of 6 mm, an inner diameter of 4 mm, and a length of 25 mm and compacted, then both ends of the graphite tube were sealed, and the surface of the graphite tube was coated with thermite. Using metal magnesium strips as the igniter, igniting the thermite, a violent thermite reaction occurs and a large amount of heat is released, which acts on the carbon nanotubes to rearrange the C-C bonds of the carbon tubes and optimize the structure. The processed carbon nanotubes are taken out from the graphite tube, and the degree of graphitization is detected by Raman spectroscopy, and the structural changes are analyzed.

example 3

[0026] Accurately weigh 2.698g (0.1mol) of nanoscale aluminum powder and 15.969g (0.1mol) of ferric oxide powder according to the molar ratio of 1:1, and mix them well to make thermite. Then commercially available CVD carbon nanotubes were placed in a graphite tube with an outer diameter of 6 mm, an inner diameter of 4 mm, and a length of 25 mm and compacted, then both ends of the graphite tube were sealed, and the surface of the graphite tube was coated with thermite. Using metal magnesium strips as the igniter, igniting the thermite, a violent thermite reaction occurs and a large amount of heat is released, which acts on the carbon nanotubes to rearrange the C-C bonds of the carbon tubes and optimize the structure. The processed carbon nanotubes are taken out from the graphite tube, and the degree of graphitization is detected by Raman spectroscopy, and the structural changes are analyzed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com