Graphene film transfer method

A graphene film and transfer method technology, applied in chemical instruments and methods, gaseous chemical plating, inorganic chemistry, etc., can solve the problems of graphene film transfer, target substrate attachment, finished film wrinkles, etc., and achieve process simplification , easy to operate, light transmittance and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

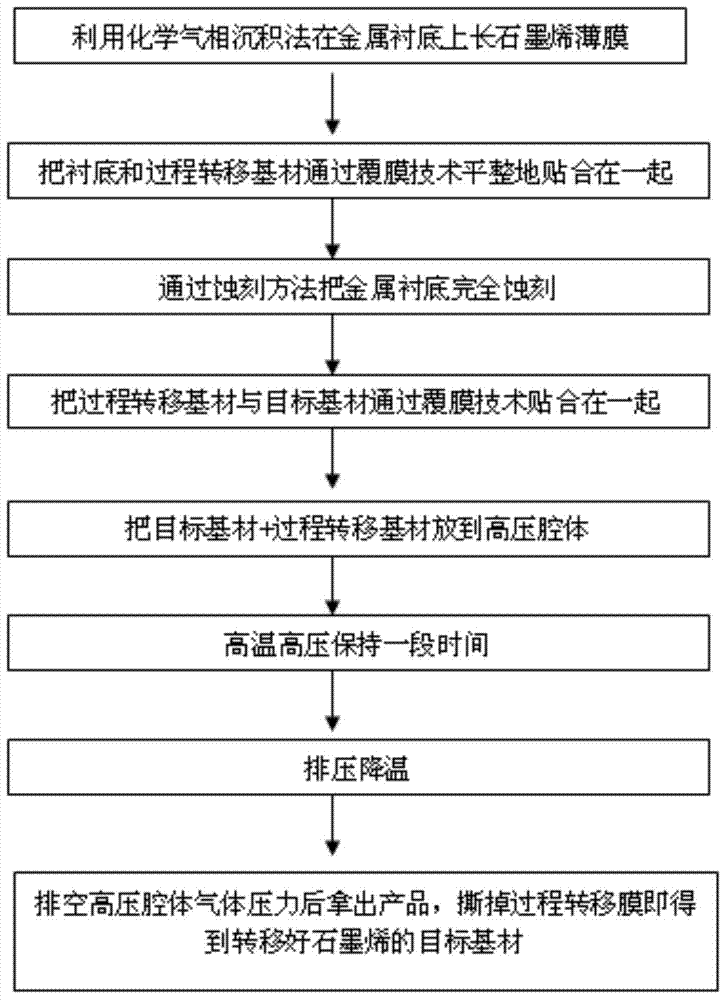

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 takes PET as the target substrate

[0025] The specific preparation method is as follows:

[0026] (1) Use 200mm*300mm*18um copper foil to grow a complete graphene film in a CVD furnace.

[0027] (2) Lay the copper foil with graphene film grown above and the process transfer film (thickness 0.125mm, PET with hot-peeling adhesive) together through a film-coated roller press. The process parameters of the film-coated roller press are: The pressure is 0.5MPa, the temperature is 70°C, and the speed is 10mm / s.

[0028] (3) Put the process-transferred PET of the above-mentioned bonding copper foil in a mixed solution of hydrochloric acid and hydrogen peroxide, etch the copper foil to obtain a semi-finished product of process-transferred PET / heat-peeling adhesive / graphene film;

[0029] (4) Clean the graphene film on the semi-finished product with pure water, and dry it with an air knife.

[0030] (5) Lay the graphene film surface of the semi-finished product a...

Embodiment 2

[0038] Example 2 takes tempered glass printed with an ink frame as the target substrate

[0039] (1) Use 200mm*300mm*18um copper foil to grow a complete graphene film in a CVD furnace.

[0040] (2) Lay the copper foil with graphene film grown above and the process transfer film (thickness 0.125mm, PET with hot-peeling adhesive) together through a film-coated roller press. The process parameters of the film-coated roller press are: The pressure is 0.5MPa, the temperature is 70°C, and the speed is 10mm / s.

[0041] (3) Put the process-transferred PET of the above-mentioned bonding copper foil in the ammonium persulfate solution, etch the copper foil to obtain a semi-finished product of process-transferred PET / thermal peel adhesive / graphene film;

[0042] (4) Clean the graphene film on the semi-finished product with pure water, and dry it with an air knife.

[0043] (5) Lay the graphene film surface of the semi-finished product above and the tempered glass printed with ink frame...

Embodiment 3

[0051] Embodiment 3 takes PMMA as the target substrate

[0052] (1) Use 200mm*300mm*18um copper foil to grow a complete graphene film in a CVD furnace.

[0053] (2) The copper foil with graphene film grown in step (1) and the process transfer film (thickness 0.125mm, PET with hot-peeling adhesive) are bonded together by a lamination roller press, and the lamination roller press The process parameters are: pressure 0.5MPa, temperature 70°C, speed 10mm / s.

[0054] (3) Place the above-mentioned process transfer film laminated with copper foil in ferric chloride solution, etch the copper foil to obtain a semi-finished product of process transfer PET / thermal peel adhesive / graphene film;

[0055] (4) Clean the graphene film on the semi-finished product with pure water, and dry it with an air knife.

[0056] (5) Lay the graphene film surface of the semi-finished product above and the 0.5mm PMMA as the target substrate (the surface of the PMMA is a non-smooth plane, roughness Rpv<1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com