Waste conveying belt reeling recovery device and method

A recycling device and conveyor belt technology, which is applied in the field of recycling devices and waste conveyor belt coiling and recycling devices, can solve the problems of easy wear of conveyor belts, low service life, economic waste, etc., and achieve the effect of facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

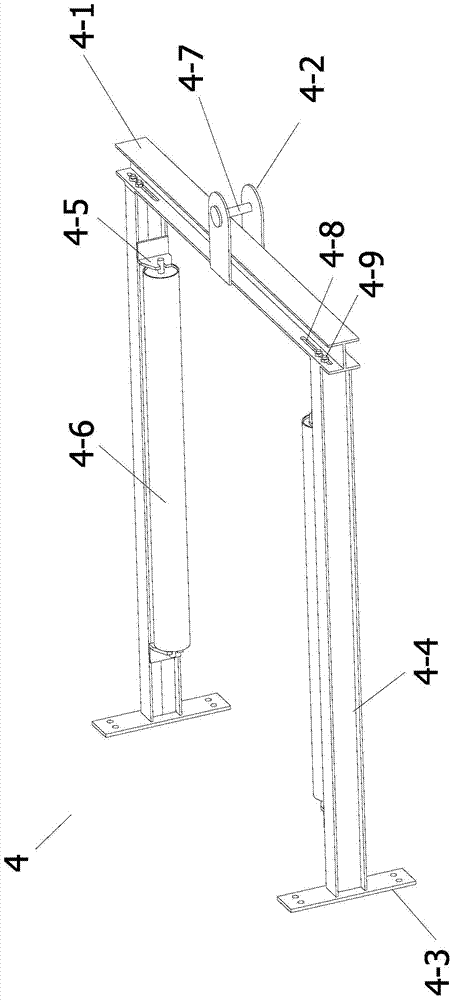

[0030] Such as Figure 1 to Figure 5 As shown, the recycling device for waste conveyor belt in this embodiment includes a roller 2 for winding up the conveyor belt 1; the outside of the side wall of the roller 2 is provided with a clamp 6 for clamping the belt head of the conveyor belt 1; The roller shafts 2-1 are respectively connected in rotation with the corresponding bearing housings 3-1, and the same side of the two bearing housings 3-1 is respectively provided with hanging plates 3-2, and each hanging plate 3-2 is fixedly connected with the traction frame 4 respectively, and the traction frame 4 has a horizontal bar 4-1 parallel to the axis of the drum 2, and the side of the horizontal bar 4-1 away from the drum 2 has a traction end 4-2 for the traction rope 5 to pass through.

[0031] The side wall of the roller 2 extends protruding eaves 2-2 respectively toward both ends along the axial direction of the roller 2; the roller shaft 2-1 is fixedly connected with the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com