Method for inducting two-dimensional periodic structure on surface of material through femtosecond laser

A periodic structure, femtosecond laser technology, applied in the field of laser applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

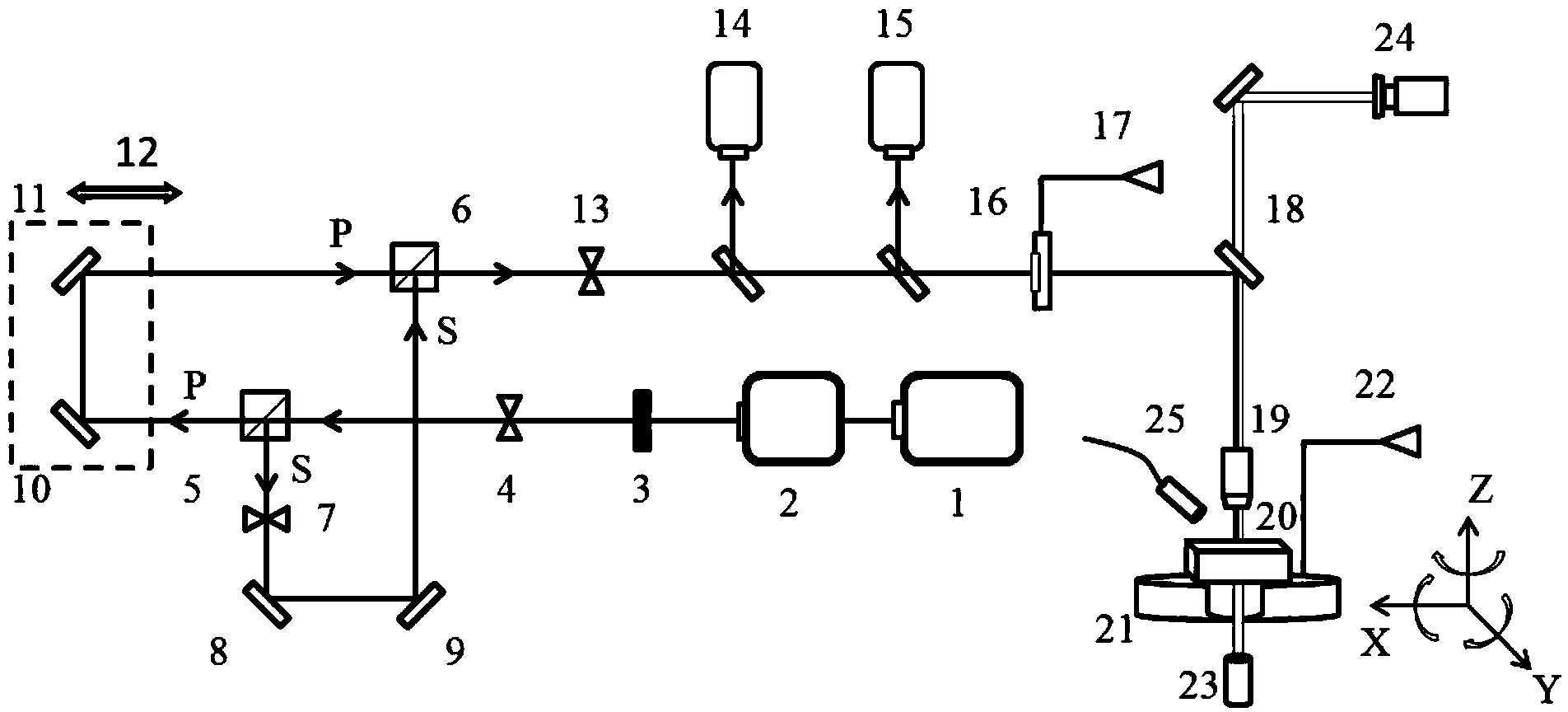

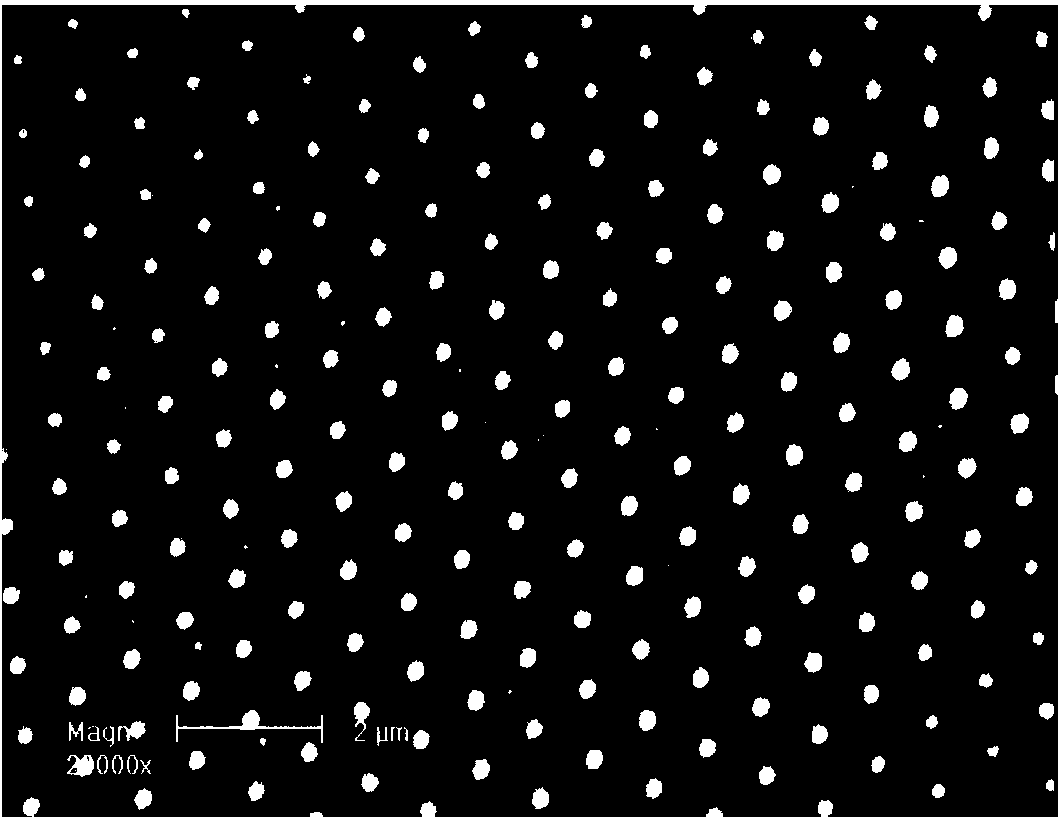

[0023] Taking the femtosecond laser variable wavelength vertical polarization double pulse processing method of the present invention to induce a two-dimensional periodic conical structure on the surface of Ge material as an example, the specific application equipment is as follows:

[0024] Femtosecond laser system 1 is a laser produced by Spectrum Physics in the United States. The laser wavelength is 800nm, the pulse width is 50fs, the repetition frequency is 1KHz, the maximum energy of a single pulse is 3mJ, and the light intensity distribution is Gaussian and linearly polarized.

[0025] The optical parametric amplifier 2 is TOPAS-C produced by American Light Conversion Company, which can continuously adjust the 800nm femtosecond laser pulse in the wavelength range of 290-2600nm with an adjustment accuracy of 0.1nm.

[0026] The structural components of the Michelson interferometer include: a polarization splitter prism 5 , a polarization combiner prism 6 , a first reflec...

Embodiment 2

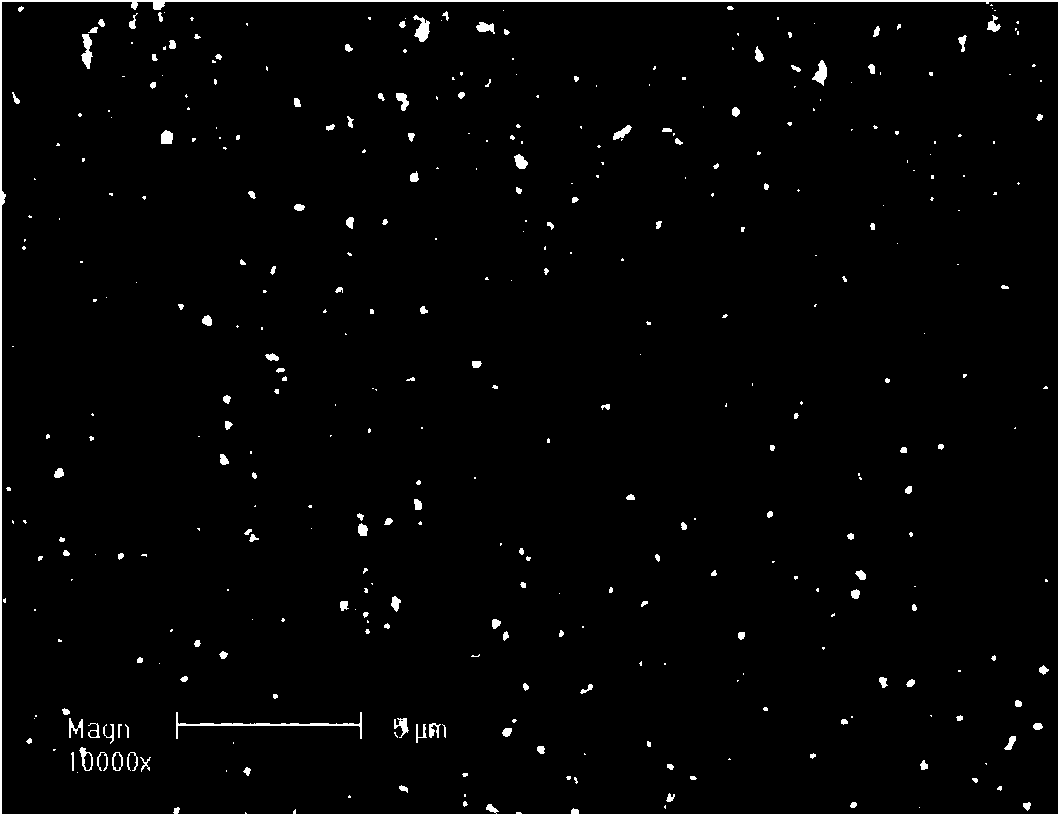

[0034] The other steps are the same as in Embodiment 1, except that: in step (1), the laser wavelength is adjusted to 620nm through the optical parametric amplifier 2, wherein the wavelength adjustment accuracy is corrected by the fiber optic spectrometer 14; the period interval of the two-dimensional periodic conical structure becomes : 700-780nm.

Embodiment 3

[0036] The other steps are the same as in Example 1, except that: in step (1), the laser wavelength is adjusted to 1000 nm through the optical parametric amplifier 2, wherein the wavelength adjustment accuracy is corrected by the fiber optic spectrometer 14; the period interval of the two-dimensional periodic conical structure becomes : 1.1-1.25μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com