Ionic liquid catalyst for C5/C6 alkane isomerization and preparation and using method of catalyst

A technology for alkane isomerization and ionic liquids, which is applied in the field of dicationic liquid catalysts, can solve problems such as difficult separation, and achieve the effects of fast reaction speed, high acid strength and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

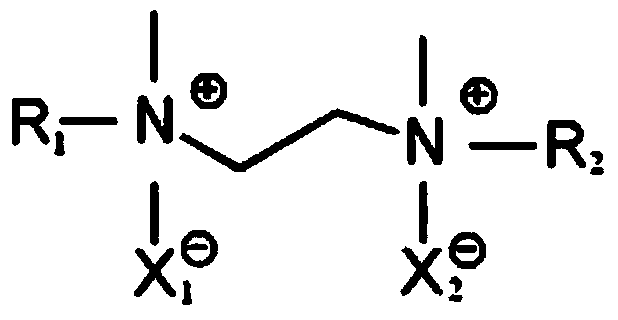

[0035] The chemical structural formula of the ionic liquid catalyst described in the present embodiment is as follows:

[0036]

[0037] where: R 1 and R 2 Respectively ethyl; X 1 and x 2 AlCl 3 Br - or Al 2 Cl 6 Br -

[0038] The synthetic method of above-mentioned ionic liquid catalyst is as follows:

[0039](1) Dissolve 0.1mol tetramethylethylenediamine and 0.2mol bromoethane in absolute ethanol, stir and react at 60°C for 2h, filter to obtain a white solid, wash 3 times with ethanol, and dry in a vacuum oven for 12h. Obtain the ionic liquid precursor.

[0040] (2) Mix 0.1mol ionic liquid precursor with 0.4molAlCl 3 Add it into an airtight container and mix evenly, and place it at 90° C. for 12 hours to prepare a strongly acidic double-center cationic ionic liquid.

[0041] The concrete operation method that the ionic liquid catalyst described in this embodiment is used for C5 alkane isomerization is:

Embodiment 2

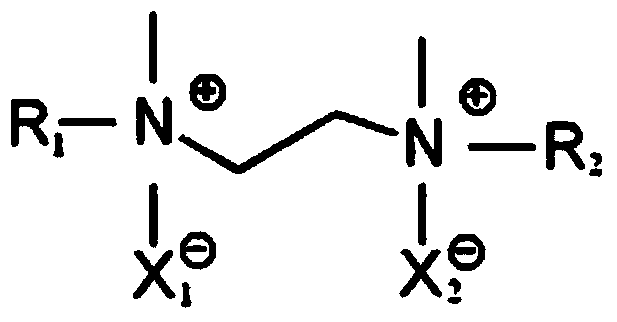

[0048] The chemical structural formula of the ionic liquid catalyst described in the present embodiment is as follows:

[0049]

[0050] where: R 1 and R 2 Respectively ethyl; X 1 and x 2 AlCl 3 Br - or Al 2 Cl 6 Br -

[0051] The synthetic method of above-mentioned ionic liquid catalyst is as follows:

[0052] (1) Dissolve 0.1mol tetramethylethylenediamine and 0.2mol bromoethane in absolute ethanol, stir and react at 80°C for 2h, filter to obtain a white solid, wash with ethanol 3 times, and dry in a vacuum oven for 12h. Obtain the ionic liquid precursor.

[0053] (2) Mix 0.1mol ionic liquid precursor with 0.3molAlCl 3 Add it into an airtight container and mix evenly, and place it at 90° C. for 12 hours to prepare a strongly acidic double-center cationic ionic liquid.

[0054] The concrete operation method that the ionic liquid catalyst described in this embodiment is used for C5 alkane isomerization is:

[0055] (1) take chlorobutane and normal pentane in the...

Embodiment 3

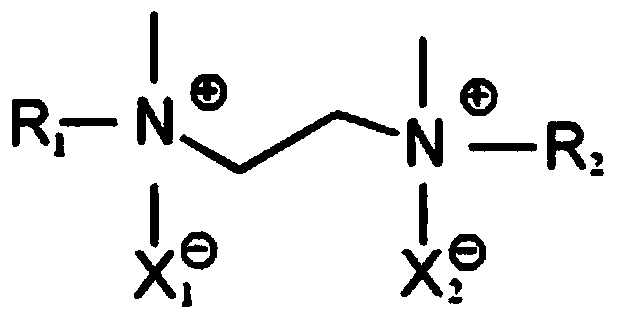

[0061] The chemical structural formula of the ionic liquid catalyst described in the present embodiment is as follows:

[0062]

[0063] where: R 1 and R 2 Respectively ethyl; X 1 and x 2 AlCl 3 Br - or Al 2 Cl 6 Br -

[0064] The synthetic method of above-mentioned ionic liquid catalyst is as follows:

[0065] (1) Dissolve 0.1mol tetramethylethylenediamine and 0.2mol bromoethane in absolute ethanol, stir and react at 80°C for 2h, filter to obtain a white solid, wash with ethanol 3 times, and dry in a vacuum oven for 12h. Obtain the ionic liquid precursor.

[0066] (2) Mix 0.1mol ionic liquid precursor with 0.3molAlCl 3 Add it into an airtight container and mix evenly, and place it at 90° C. for 12 hours to prepare a strongly acidic double-center cationic ionic liquid.

[0067] The method that the ionic liquid catalyst described in the present embodiment is used for C5 alkane isomerization is:

[0068] (1) take chlorobutane and normal pentane in the ratio of vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com