Gas deduster

A dust collector and gas technology, applied in the field of dust removal equipment, can solve the problems of high filter bag replacement cost, dust escape and high pressure resistance, and achieve the effect of reducing the replacement cost of spare parts, avoiding secondary pollution and overcoming dust escape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

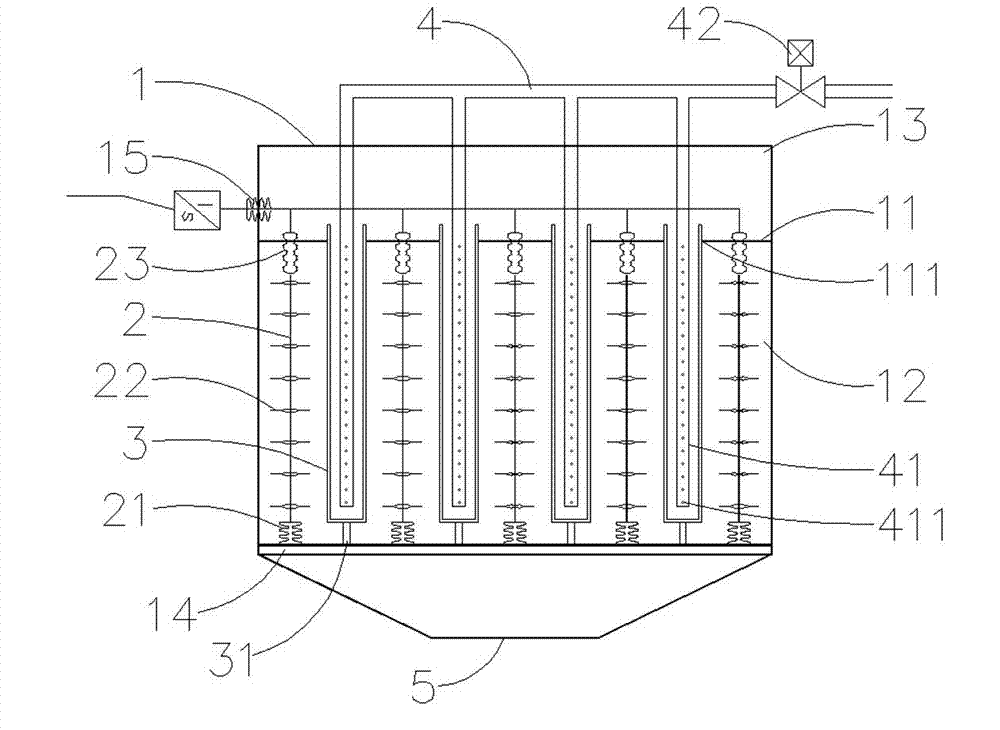

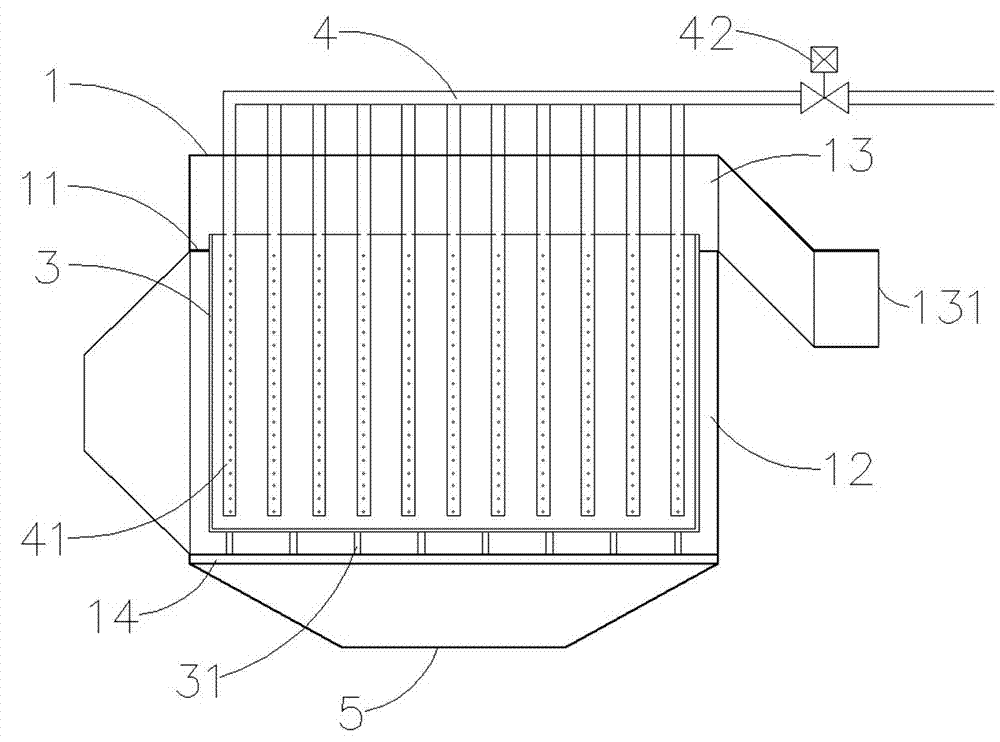

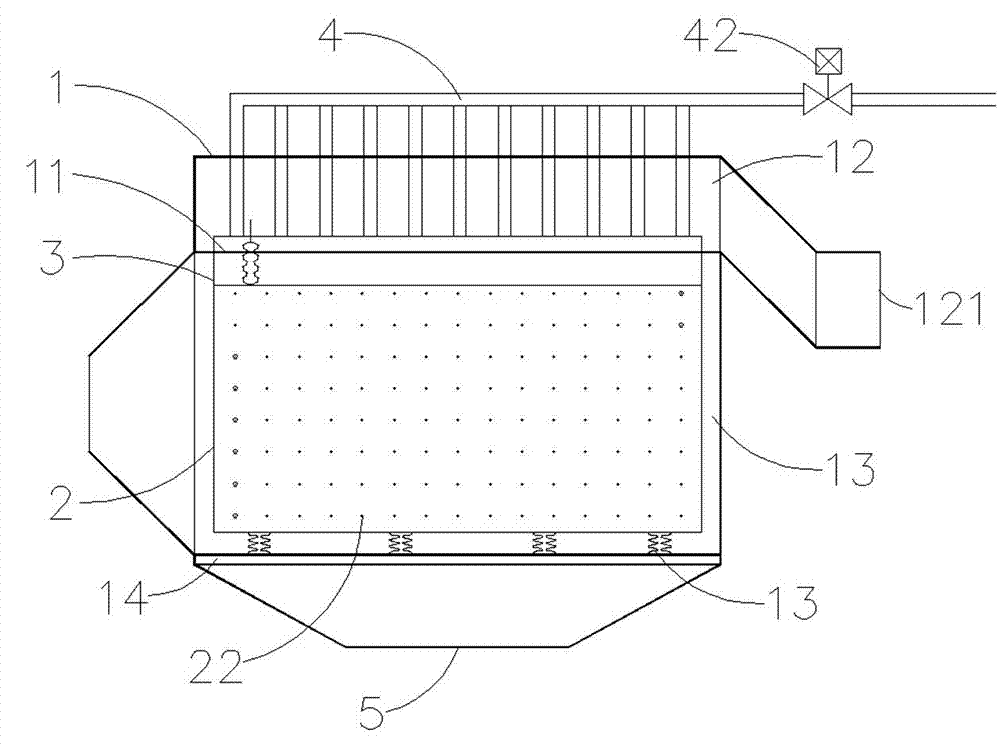

[0033] Embodiment 1: During work, the dusty gas enters the dust removal chamber 12 through the air inlet 121, passes through the high-porosity porous box wall of the dust collection box 3, and the clean gas enters the clean gas chamber 13 from the vent 111 on the partition 11 , and finally flow out from the air outlet 131, while the dust particles stay on the outside of the box wall under the filtering and electrostatic adsorption of the box wall. When the dust particles on the outer wall of the dust collection box 3 are thick, the pressure difference between the inside and outside of the dust collection box 3 increases, the control system starts the electromagnetic control valve 42, and at the same time the power supply of the discharge electrode plate 2 is cut off, and the gap between the discharge electrode plate 2 and the dust collection box 3 The electrostatic field disappears, and the soot blowing pipe 41 ejects high-pressure gas from each air injection hole 411, and blow...

Embodiment 2

[0034] Embodiment 2: When working, turn on the power supply, and the high-voltage direct current with a voltage level of 60000V to 70000V forms a high-voltage electric field through the discharge electrode plate 2, and the surrounding gas is ionized by corona discharge through the metal thorns 22 on the discharge electrode plate 2 to form charged When ions and dust particles in the gas pass through the high-voltage electrostatic field from all around, they collide with the positive and negative ions and electrons between the electrodes and are charged (or charged during the ion diffusion movement), and the dust particles with electrons and ions are charged in the electric field force It moves to the dust collecting box 3 under the action of the action and electrostatic accumulation is attached on the dust collecting box 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com